Glass fiber reinforced plastic double-deck oil tank and manufacture technology thereof

A double-layer oil tank and manufacturing process technology, applied in the direction of container, packaging, transportation and packaging, etc., can solve the problems of many bubbles in the outer tank, insufficient sensitivity of interlayer detection, and unsightly appearance, so as to ensure permeability and reduce human hazards , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

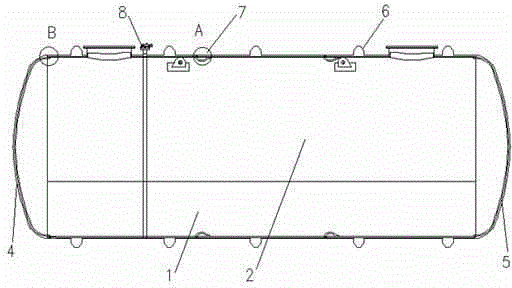

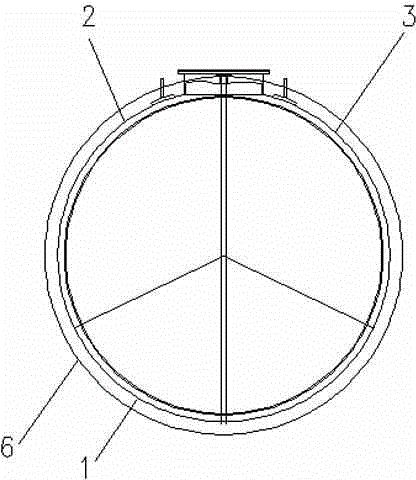

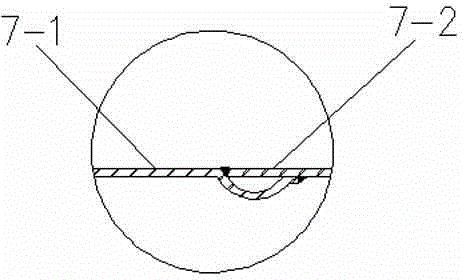

[0027] Such as Figure 1-4 As shown, a fiberglass double-layer oil tank is a kind of fiberglass double-layer oil tank, which includes an oil tank body with an oil inlet on the top, a leak detector 8, and a circumferential support structure 6 for transportation and installation. The oil tank body A steel tank body including an inner layer, the steel tank body includes a middle steel plate 7-2, side steel plates 7-1 are connected to both sides of the middle steel plate 7-2, and the openings at both ends of the side steel plate 7-1 A sealing steel plate 4-1 is connected, and the middle steel plate 7-2, the side steel plate 7-1 and the sealing steel plate 4-1 are fixedly connected to form a closed cavity; the periphery of the steel tank body is wrapped with an intermediate interlayer, and the The outer periphery of the middle interlayer is provided with a glass fiber reinforced plastic outer cladding, and the glass fiber reinforced plastic outer cladding includes the first RTM are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com