Emulsified lipstick and preparation method thereof

A lipstick and hardening agent technology, applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of inability to produce finished product rate, limitation of lipstick function, and generation of a large number of bubbles, etc., to stimulate microvascular circulation, increase skin elasticity, and lighten lips. The effect of grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

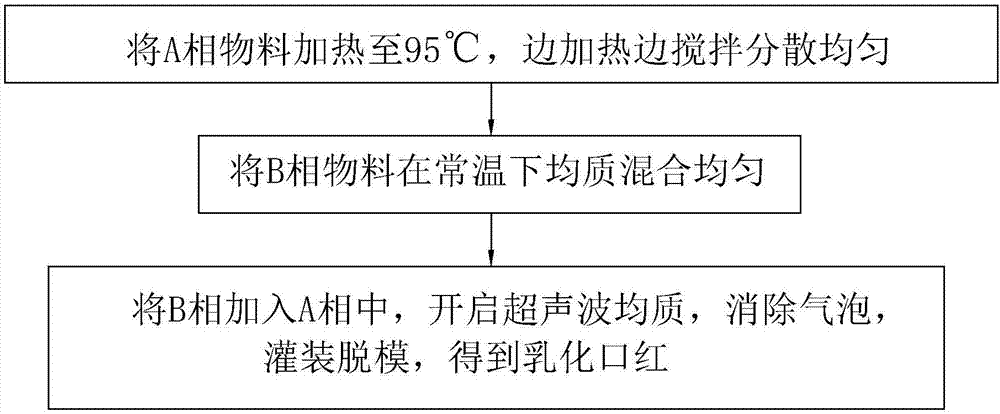

[0050] Embodiment 1: as figure 1 Shown, a kind of emulsified lipstick, each component and its corresponding weight percent are as shown in table 1,

[0051] and prepared by the following steps:

[0052] Step 1, tridecyl trimellitate, hydrogenated polyisobutylene, diisostearyl malate, caprylic / capric triglyceride, bis-diglyceryl polyacyl adipate-2, jojoba (SIMMONDSIA CHINENSIS) seed oil, polyethylene, beeswax, VP / hexadecene copolymer, diphenylsiloxyphenyl trimethicone, polyglyceryl-2 triisostearate, di Polypentaerythritol tri-polyhydroxystearate, phytosterol / octyldodecanyl lauroyl glutamate, preservatives, colorants are heated to 90°C, stirred while heating, the stirring speed is 30 rpm, dispersed After 4 hours, until the material body and pigment are evenly dispersed, and there is no obvious particle impurity, after passing the inspection, it is transferred to the molten material barrel of the filling machine, kept warm, and forms A phase;

[0053] Step 2, homogeneously mix...

Embodiment 2-10

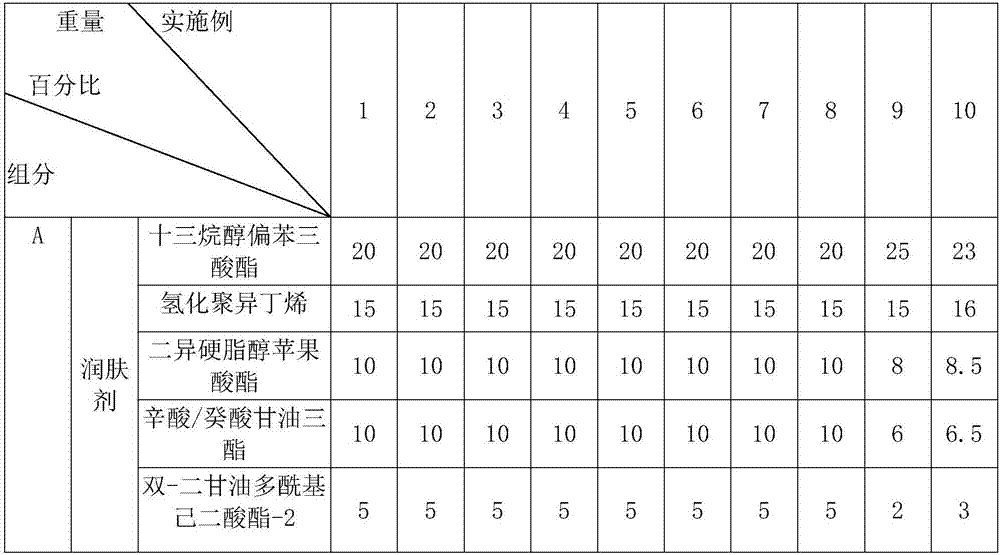

[0056] Example 2-10: An emulsified lipstick, the difference from Example 1 is that each component and its corresponding weight percentage are shown in Table 1.

[0057] Each component and its weight percent in table 1 embodiment 1-10

[0058]

[0059]

Embodiment 11-21

[0060] Examples 11-21: an emulsified lipstick, the difference from Example 3 is that each component and its corresponding weight percentage are shown in Table 2.

[0061] Each component and weight percentage thereof in table 2 embodiment 11-21

[0062]

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com