Manufacturing technology of oil inflow valve casting

A manufacturing process and oil inlet valve technology, which is applied in the field of oil inlet valve casting manufacturing technology, can solve the problems of inability to set up gas outlet risers, inability to place core bones, easy formation of air bubbles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A manufacturing process for oil inlet valve castings, the innovation of which is: the steps are as follows

[0020] 1) First, use metal to make the metal template required for the oil inlet valve;

[0021] 2) Next, heat the metal template to 180~280°C, and then cover the mold sand hardened by heat on the metal template to solidify the molding sand;

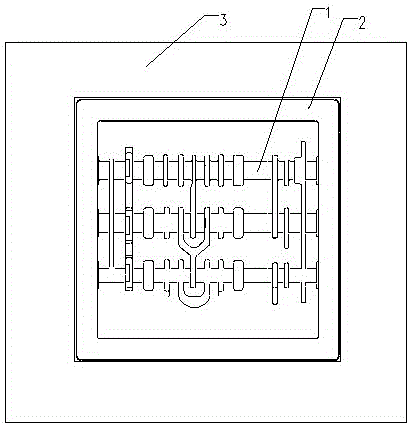

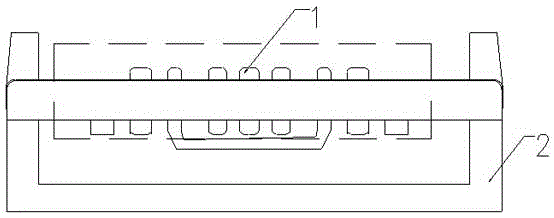

[0022] 3) Then, heat and solidify the molding sand to form the upper and lower shells 2. The top of the upper shell 2 has several frustum-shaped cavities for forming bosses on the surface of the valve body. The upper shell above the cavities Type 2 is provided with a vertical vent connecting the cavity and the outside of the shell, and on the upper surface of the upper shell there are several horizontal diversion grooves connecting the upper port of the vertical vent;

[0023] 4) Then, form the sand core 1 of the oil inlet valve through chromite sand, and set the sand core 1 horizontally in the shell type 2, and form an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com