Device and technology for repairing pipeline circumferential weld defects through epoxy steel sleeve

A technology of girth weld and epoxy steel, which is applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of embrittlement and cracking of filled resin materials, unsatisfactory requirements, and design of solidified bubble sleeves. Achieve the effect of solving embrittlement cracking, improving integrity and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

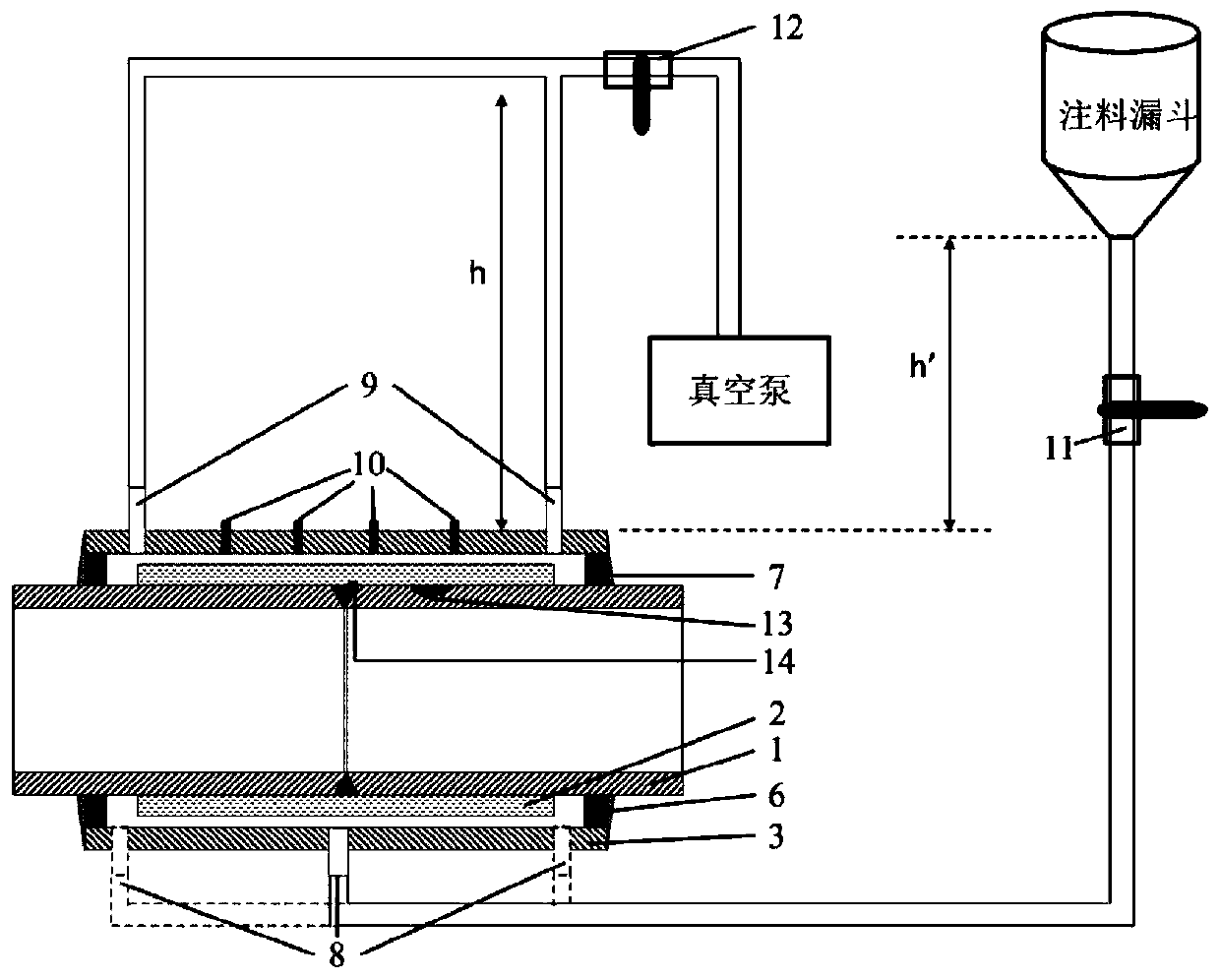

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

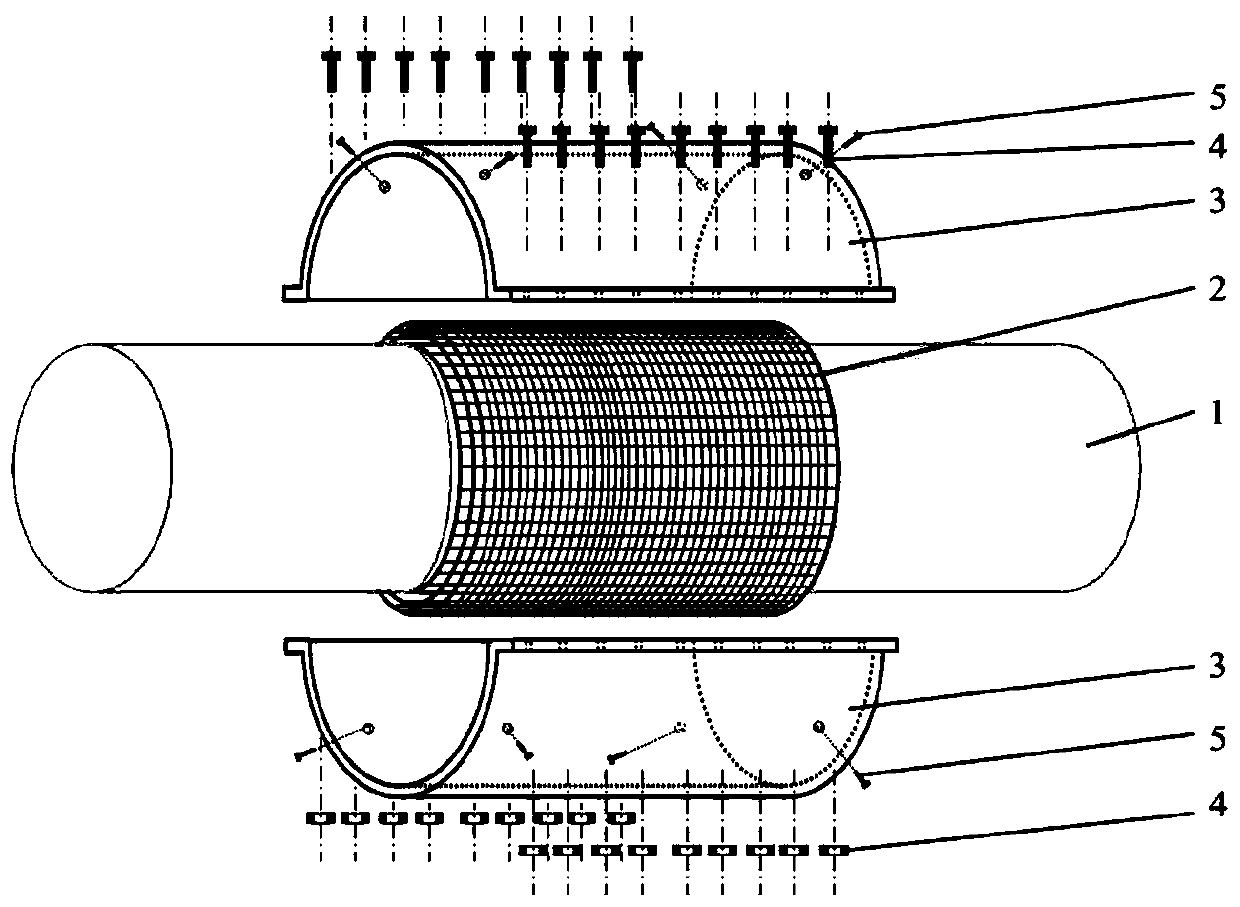

[0034] Devices for repairing defects in pipe girth welds such as figure 1 Shown:

[0035] Composite epoxy steel sleeve

[0036] 1) Sleeve material and size design

[0037] a) The material of the steel sleeve is made of the same material as the pipeline to be repaired 1 or higher than the steel grade of the pipeline. For high-grade steel pipelines, the use of high-grade steel sleeves can greatly reduce the wall thickness of the steel shell and reduce the weight. Provide convenience for construction.

[0038] b) The wall thickness of the steel sleeve is designed according to the following formula:

[0039]

[0040] In the formula: p - the maximum allowable pressure of the pipeline, in megapascals (MPa);

[0041] D - the inner diameter of the sleeve, in millimeters (mm);

[0042] σ s - the specified minimum yield strength of the sleeve material, in megapascals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com