Polarizer attaching device for liquid crystal display

A technology for attaching polarizers and liquid crystal displays. It is applied in the directions of instruments, optics, and nonlinear optics. It can solve the problems of low attachment positioning accuracy and affecting the quality of polarizer patches, and achieve good attachment effects and patch quality. Good, avoid the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

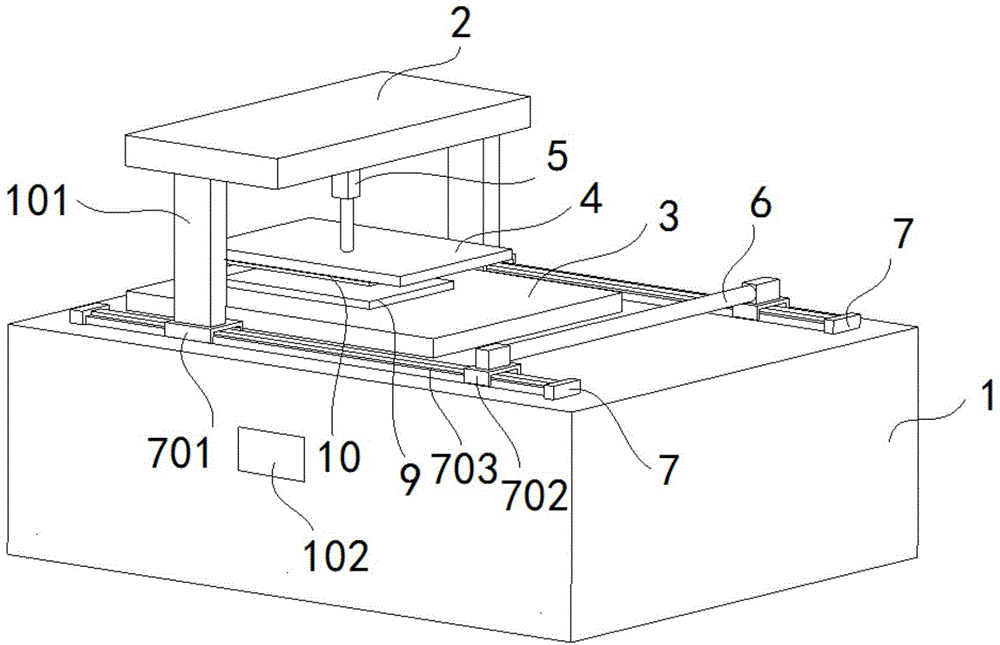

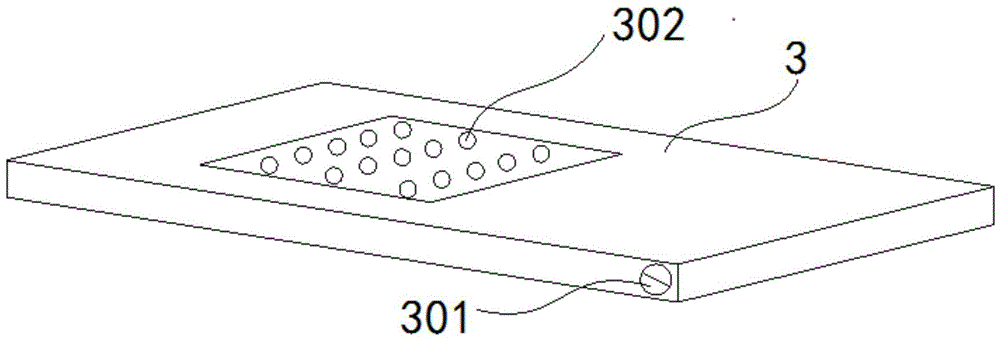

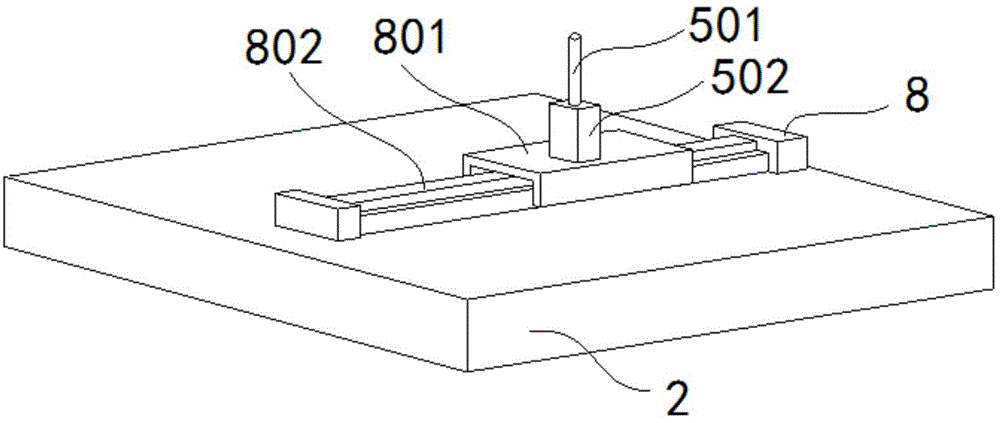

[0026] Such as figure 1 As shown, a polarizer attaching device for a liquid crystal display of the present invention includes: a base 1 , an attaching platform 3 , an adsorption plate 4 and a pressing roller 6 .

[0027] The base 1 is a rectangular parallelepiped abutment, the upper surface of the base 1 is provided with a sliding frame 101 respectively, and the upper surface of the base 1 is respectively provided with a first driving device 7 on both sides. In this embodiment, the The sliding frame 101 is a rectangular sliding frame, and the sliding frame 101 is movably arranged on both sides of the attachment platform 3 through the first driving device 7, the first driving device 7 is a linear slide rail device, and the first driving device 7 includes a first linear sliding rail 703 arranged on both sides of the base 1 and two first sliding blocks 701 and two second sliding blocks 702 that can slide on the linear sliding rails, the sliding frame 101 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com