Rigid panel adhesion method and smearing module utilized thereby

A hard board and coating technology, applied in the directions of bonding methods, chemical instruments and methods, and devices for coating liquids on the surface, etc., can solve the problems of increasing time, cost, difficulties, etc. The effect of improving the bonding strength and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0046] The method for laminating rigid boards of the present invention is suitable for bonding between two rigid boards, such as pasting a rigid touch panel on the surface of a liquid crystal display. The present invention is not limited to this embodiment, so it will be described in detail below "Rigid board" collectively refers to all rigid boards to be pasted.

[0047] Please refer to figure 1 As shown, it is a preferred embodiment of the present invention, and the hard board bonding method includes a coating step S1 and a pressing step S2.

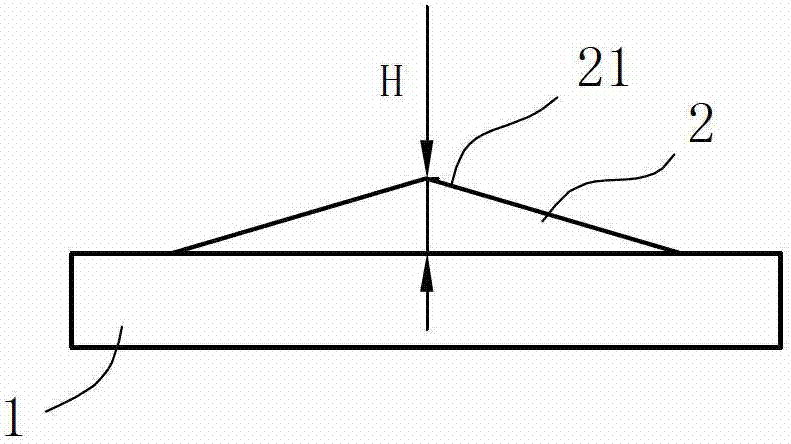

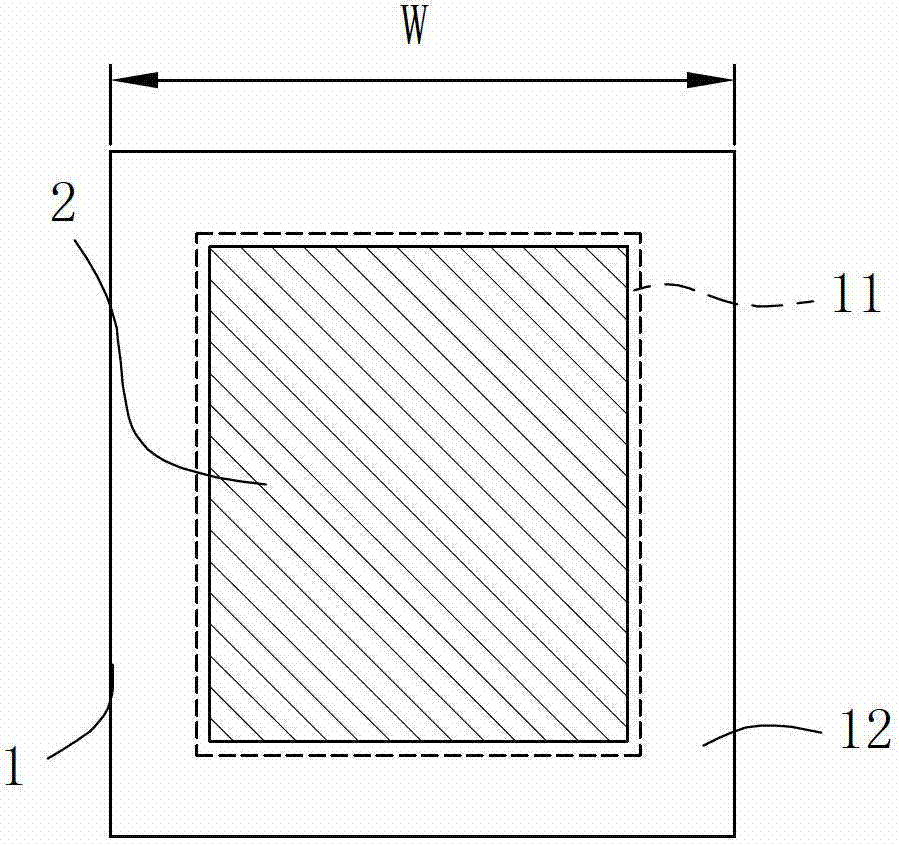

[0048] Please refer to Figures 2a to 2f As shown, the coating step S1 is to coat a glue 2 on the surface of a hard board 1, and the glue 2 only has a contact portion 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com