Damping oil composition for damper as well as preparation method thereof

A damping oil and composition technology, applied in the field of damping oil composition and its preparation, can solve problems such as unsatisfactory buffering effect, difficulty in opening and closing, increased damping force, etc., achieve moderate speed, simple and easy preparation process, Effect of small change in viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to another aspect of the present invention, there is provided a method for preparing a damping oil composition for a damper, comprising: (a) heating polyisobutylene to 70-100°C, and then mixing it with silicone oil to obtain a mixed solution; (b) mixing liquid hydrocarbon adding the mixture into the mixed solution, and stirring to mix uniformly; and (c) adding hydrogenated rosin to the solution obtained in step (b), mixing and stirring uniformly to prepare a damping oil composition.

[0025] Preferably, in the step (a), since the polyisobutylene is mixed with the silicone oil with higher solubility, more organic matter can be dissolved, and the solubility of the mixed solution will be increased.

[0026] Preferably, the polyisobutene is heated to a temperature in the range of 70-100°C, more preferably 75-90°C, even more preferably 80°C.

[0027] According to a preferred embodiment of the present invention, the temperature of the mixed solution is maintained at...

Embodiment 1

[0032] Heat 5 parts by weight of polyisobutylene (produced by Shandong Hongrui Petrochemical Co., Ltd.) with an average molecular weight of 20,000 to 80°C, and mix with 1 part by weight of benzyl silicone oil with an average molecular weight of 2000 (produced by Dongguan Kefeng Textile Auxiliaries Industrial Co., Ltd.) were mixed uniformly to obtain a mixed solution. Then add 1.5 parts by weight of civil aviation kerosene JET B (produced by Xingxiang Chemical Co., Ltd.) to the mixed solution kept at 80°C and mix well, then add dihydrorosin (produced by Tianjin Jinweier Chemical Co., Ltd.) in the mixed solution Production) 0.5 parts by weight were mixed evenly to prepare damping oil 1.

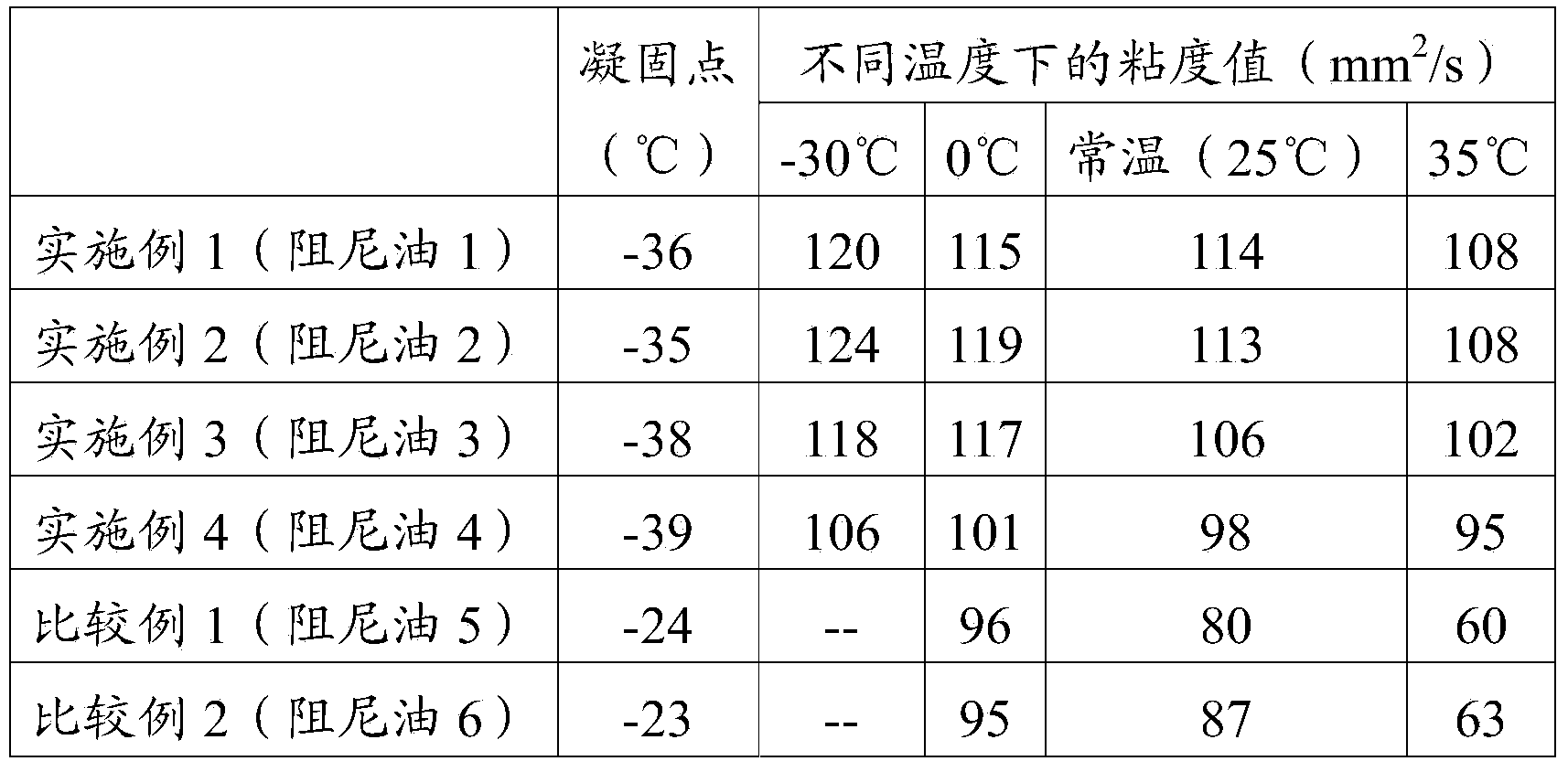

[0033] Use the freezing point detector TC20 to measure the freezing point of the damping oil 1, and use the SNB-3 digital (LCD) viscosity measuring instrument to measure the damping oil 1 at -30°C, 0°C, normal temperature (~25°C) and 35°C. Viscosity, measurement result is shown in table 1.

Embodiment 2

[0035] Heat 5 parts by weight of polyisobutylene (produced by Shandong Hongrui Petrochemical Co., Ltd.) with an average molecular weight of 10,000 to 80°C, and mix it with 1 part by weight of benzyl silicone oil with an average molecular weight of 2,500 (produced by Dongguan Kefeng Textile Auxiliaries Industrial Co., Ltd.) were mixed uniformly to obtain a mixed solution. Then add 2 parts by weight of civil aviation kerosene JET B (produced by Xingxiang Chemical Co., Ltd.) to the mixed solution kept at 80°C and mix well, then add dihydrorosin (produced by Tianjin Jinweier Chemical Co., Ltd.) in the mixed solution Production) 1 weight part was mixed uniformly, thereby preparing damping oil 2.

[0036] The freezing point of the damping oil 2 was measured using the freezing point detector TC20, and the damping oil 2 was measured at -30°C, 0°C, normal temperature (~25°C) and 35°C using the SNB-3 digital (LCD) viscosity measuring instrument. Viscosity, measurement result is shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com