Hole sealing process for magnesium-aluminum alloy

A magnesium-aluminum alloy, sealing technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of easy change of aluminum alloy color tone, unsatisfactory anti-corrosion effect, unstable sealing effect, etc. Anti-corrosion effect, good stabilizing effect and strong binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

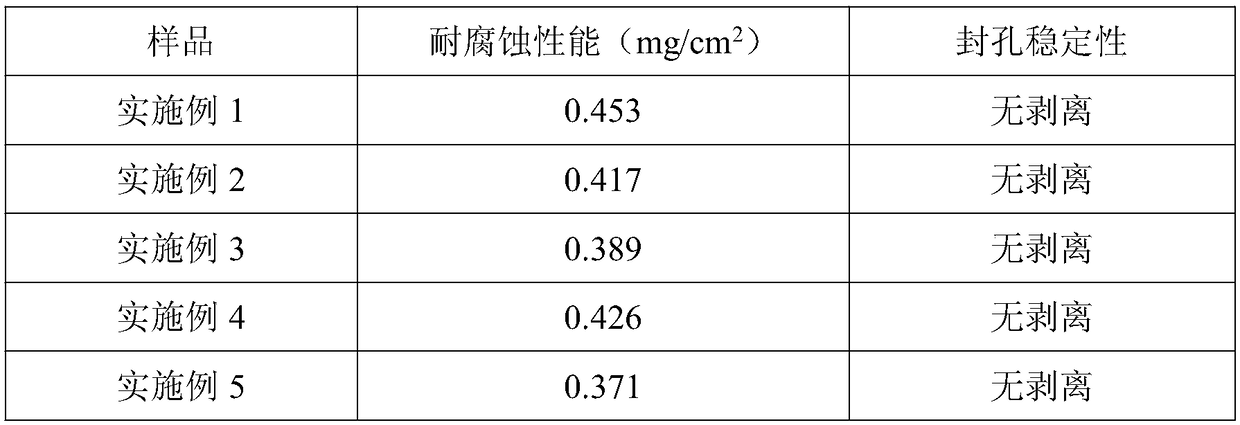

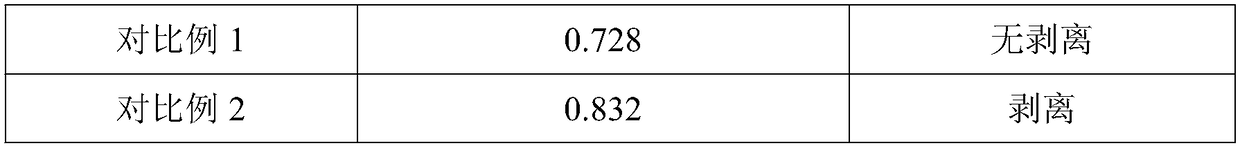

Examples

Embodiment 1

[0021] A magnesium-aluminum alloy sealing process, comprising the following steps:

[0022] S1. Wash the magnesium-aluminum alloy with water, degrease with lye, polish the electrolyte, anodize it, wash it with deionized water, and dry it with cold air to obtain a coated magnesium-aluminum alloy for use;

[0023] S2. In parts by weight, add 12 parts of ethyl orthosilicate to 40 parts of ethanol, then add 80% acetic acid to adjust the pH value to 4.6, and keep stirring for 35 minutes to obtain Sol A;

[0024] S3. In parts by weight, add 7 parts of butyl titanate to 60 parts of ethanol and mix evenly, then slowly add 70% acetic acid to adjust the pH value to 3.8, and continue stirring for 40 minutes to obtain Sol B;

[0025] S4. In parts by weight, add 30 parts of stearic acid to 90 parts of isopropanol and mix evenly, then add Sol A and Sol B, then raise the temperature to 78°C in a water bath, and stir at 1250r / min for 3min to obtain Sealing solution, put the coated magnesium-...

Embodiment 2

[0029] A magnesium-aluminum alloy sealing process, comprising the following steps:

[0030] S1. Wash the magnesium-aluminum alloy with water, degrease with lye, polish the electrolyte, anodize it, wash it with deionized water, and dry it with cold air to obtain a coated magnesium-aluminum alloy for use;

[0031] S2. In parts by weight, add 13 parts of ethyl orthosilicate to 40 parts of ethanol, then add 70% acetic acid to adjust the pH value to 5, and keep stirring for 40 minutes to obtain Sol A;

[0032] S3. In parts by weight, add 5 parts of butyl titanate to 60 parts of ethanol and mix evenly, then slowly add 75% acetic acid to adjust the pH value to 4, and continue stirring for 30 minutes to obtain Sol B;

[0033] S4. In parts by weight, add 35 parts of stearic acid to 90 parts of isopropanol and mix evenly, then add sol A and sol B, then raise the temperature to 80°C in a water bath, and stir at 1000r / min for 4min to obtain Sealing solution, put the coated magnesium-alum...

Embodiment 3

[0037] A magnesium-aluminum alloy sealing process, comprising the following steps:

[0038] S1. Wash the magnesium-aluminum alloy with water, degrease with lye, polish the electrolyte, anodize it, wash it with deionized water, and dry it with cold air to obtain a coated magnesium-aluminum alloy for use;

[0039] S2. In parts by weight, add 10 parts of tetraethyl orthosilicate to 40 parts of ethanol, then add 75% acetic acid to adjust the pH value to 5.3, and keep stirring for 30 minutes to obtain Sol A;

[0040] S3. In parts by weight, add 6 parts of butyl titanate to 60 parts of ethanol and mix evenly, then slowly add 80% acetic acid to adjust the pH value to 3.5, and continue stirring for 36 minutes to obtain Sol B;

[0041] S4. In parts by weight, add 38 parts of stearic acid to 90 parts of isopropanol and mix evenly, then add Sol A and Sol B, then raise the temperature to 80°C in a water bath, and stir at 1000r / min for 4min to obtain Sealing solution, put the coated magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com