Electrically-operated mechanism

An electric operating mechanism, the technology of the operating mechanism, applied in the protection switch operation/release mechanism, the power device inside the switch, etc., can solve the problems of high manufacturing cost, high noise, slow batch processing speed, etc., to save the manufacturing cost and mechanism. Simple volume, the effect of avoiding safety accidents

Inactive Publication Date: 2008-10-29

崔剑忠

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the current low-voltage electrical appliance industry, the existing electric operating mechanisms and motors generally use DC permanent magnet motors and AC series motors. The use of DC permanent magnet motors requires switching power supply technology that uses AC power to invert DC power. In my country's power grid When the quality of the power supply is not very good, in order to make the switching power supply operate more reliably, the manufacturing process of the switching power supply requires high manufacturing costs and is quite expensive, and the DC permanent magnet motor itself has the defects of high speed and low power, resulting in The number of stages of the reduction mechanism of the electric operating mechanism must be increased, the gear module must be small and the strength is poor, otherwise the DC motor will not be able to move the entire electric operating mechanism, making the structure of the electric operating mechanism complex, and the circuit board and the reduction mechanism occupy the power of the electric operating mechanism. Most of the space in the mechanism is relatively large, which greatly increases the manufacturing cost

The worm gear using the AC series motor deceleration mechanism requires high manufacturing precision, slow batch processing speed, and the noise when the motor rotates, the current when the motor starts is large, the manufacturing cost is high, and the volume is large. This structure has many disadvantages. The industry is in a phase-out trend

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

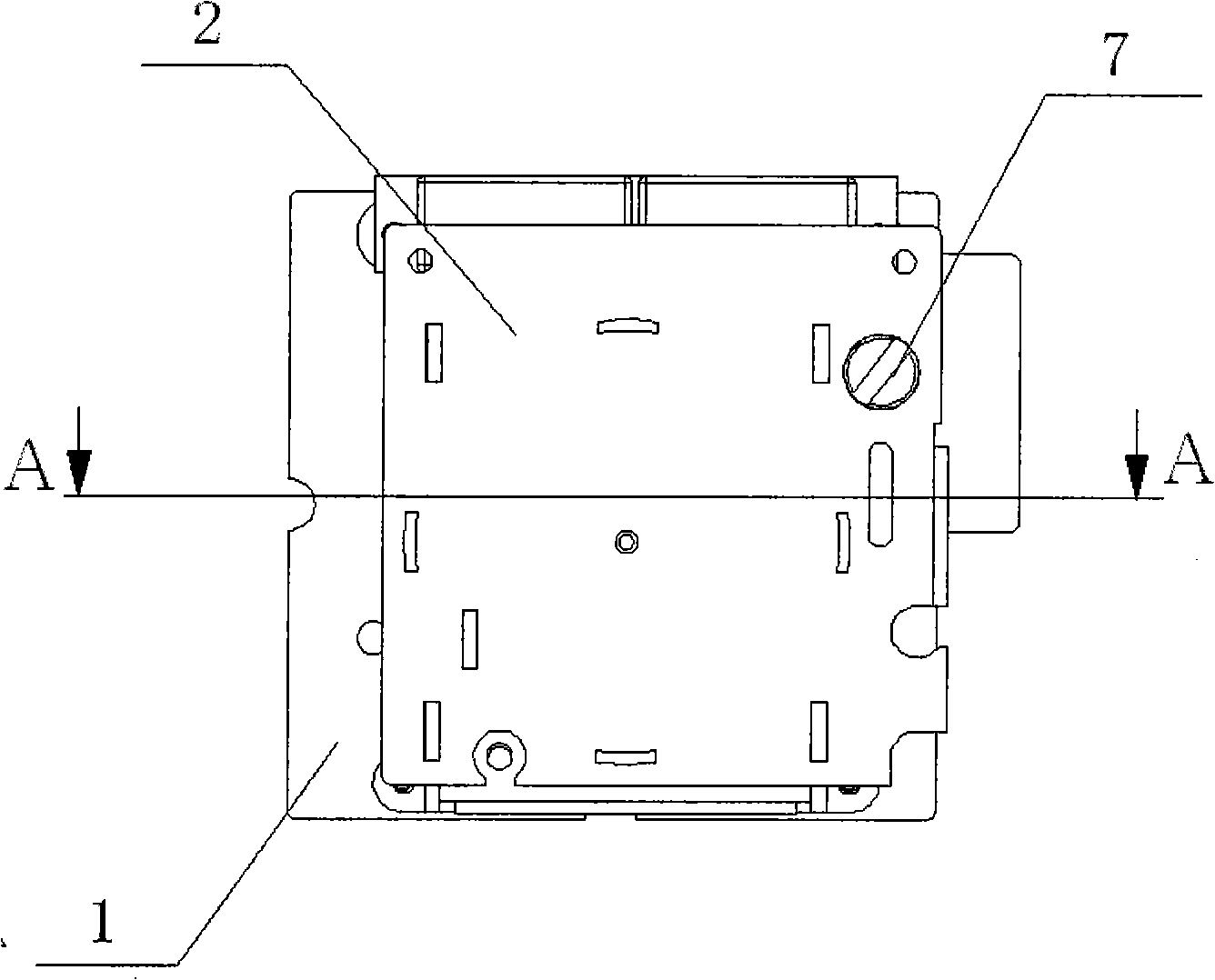

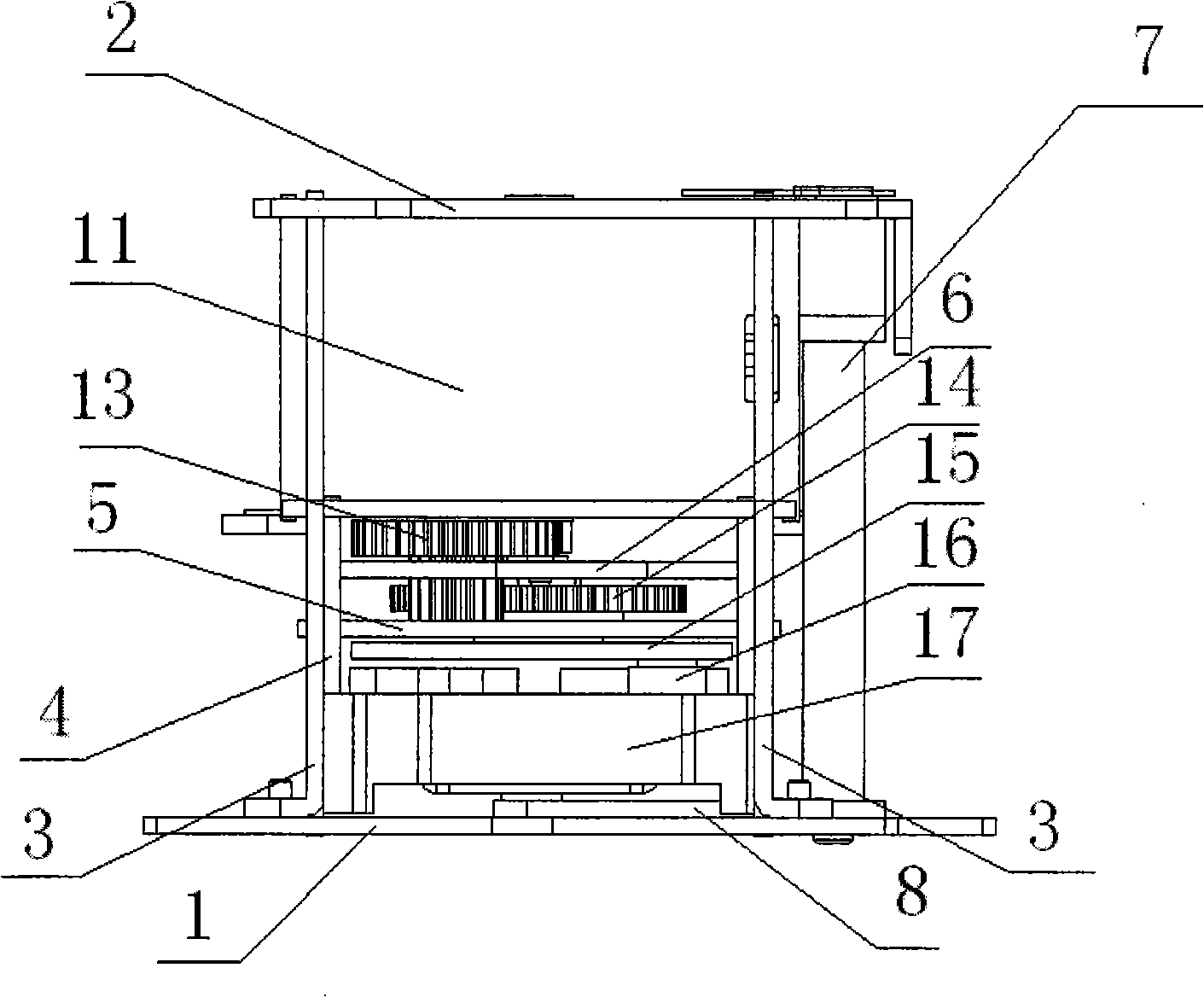

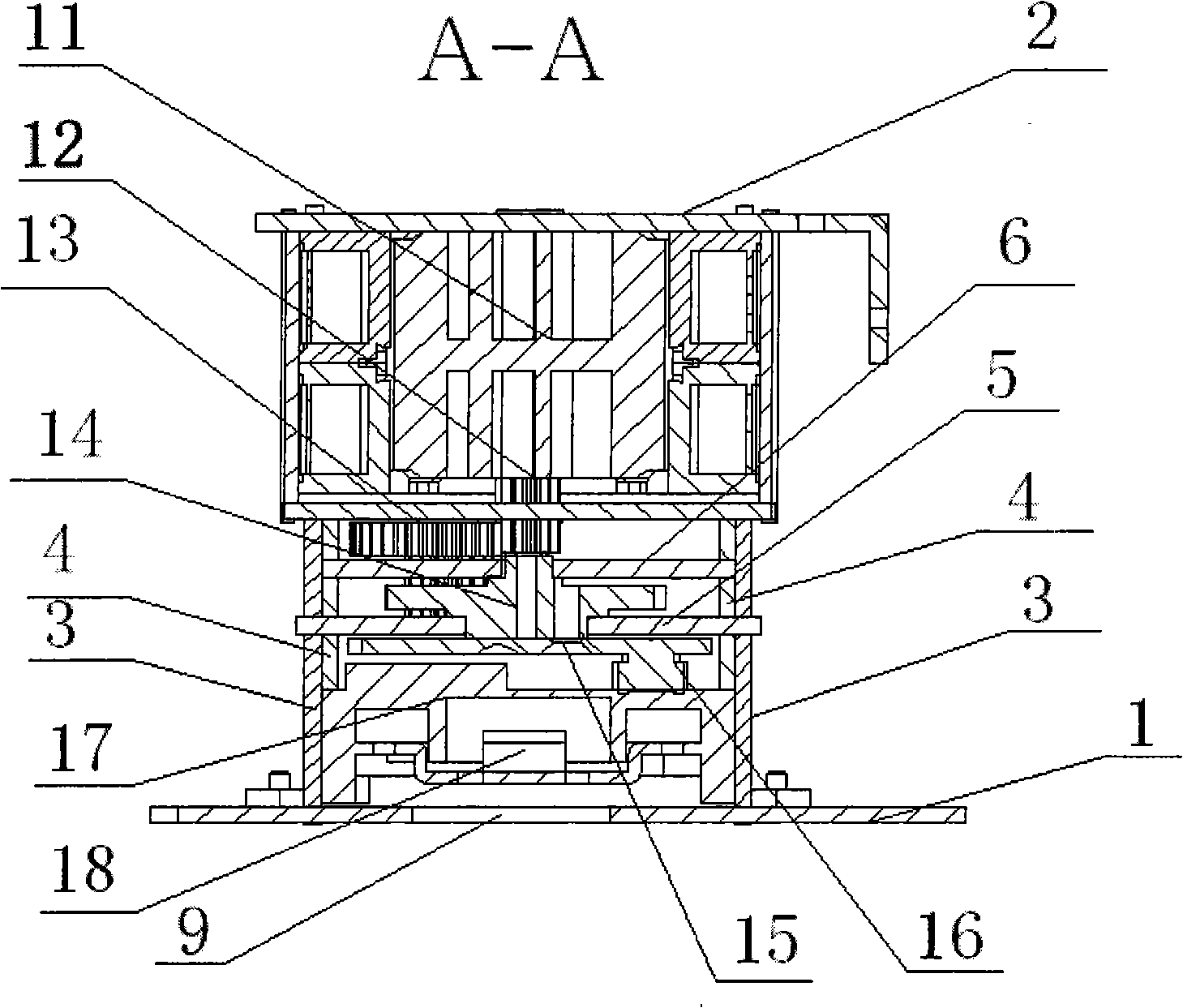

The invention relates to an electric operation mechanism which includes a bracket, a motor, a reducing mechanism and an operation mechanism. The invention is characterized in that the motor is an AC synchronous motor; the AC synchronous motor is connected with the reducing mechanism through a motor output shaft; the reducing mechanism is connected with the operation mechanism; the invention uses the AC synchronous motor to replace a traditional DC magnetoelectric machine and a traditional AC series excited machine; the AC synchronous motor has the advantages of simple mechanism, smaller size as well as proper rotating speed and power; therefore, the structure of the reducing mechanism connected with the AC synchronous motor is simple; both the AC synchronous motor and the reducing mechanism greatly save the size of electric operation and save the manufacture cost.

Description

Electric operating mechanism technical field The invention relates to a power distribution equipment, in particular to an electric operating mechanism of a molded case circuit breaker in a power distribution line. Background technique In the current low-voltage electrical appliance industry, the existing electric operating mechanisms and motors generally use DC permanent magnet motors and AC series motors. The use of DC permanent magnet motors requires switching power supply technology that uses AC power to invert DC power. In my country's power grid When the quality of the power supply is not very good, in order to make the switching power supply operate more reliably, the manufacturing process of the switching power supply requires high manufacturing costs and is quite expensive, and the DC permanent magnet motor itself has the defects of high speed and low power, resulting in The number of stages of the reduction mechanism of the electric operating mechanism must be incre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H3/26H01H71/70

Inventor 崔剑忠

Owner 崔剑忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com