Hydraulic axial plunger type transmission roller capable of adjusting speed

A transmission roller and axial column technology, which is applied in the field of hydraulic axial plunger transmission rollers and belt conveyor transmission rollers, can solve the problems of complicated installation and debugging, increased production costs, and increased maintenance costs of supporting facilities, and achieves The effect of reducing production costs and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

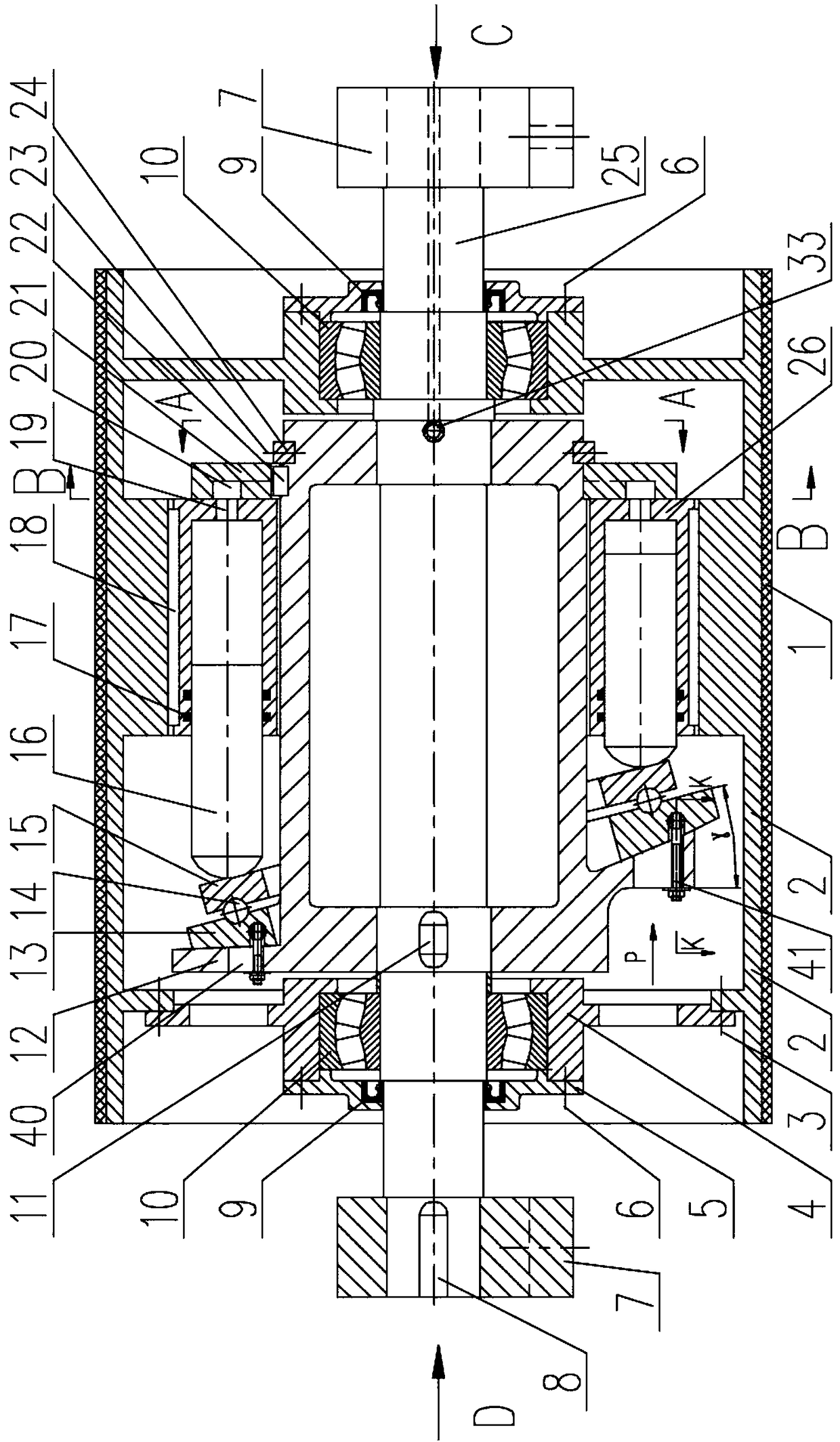

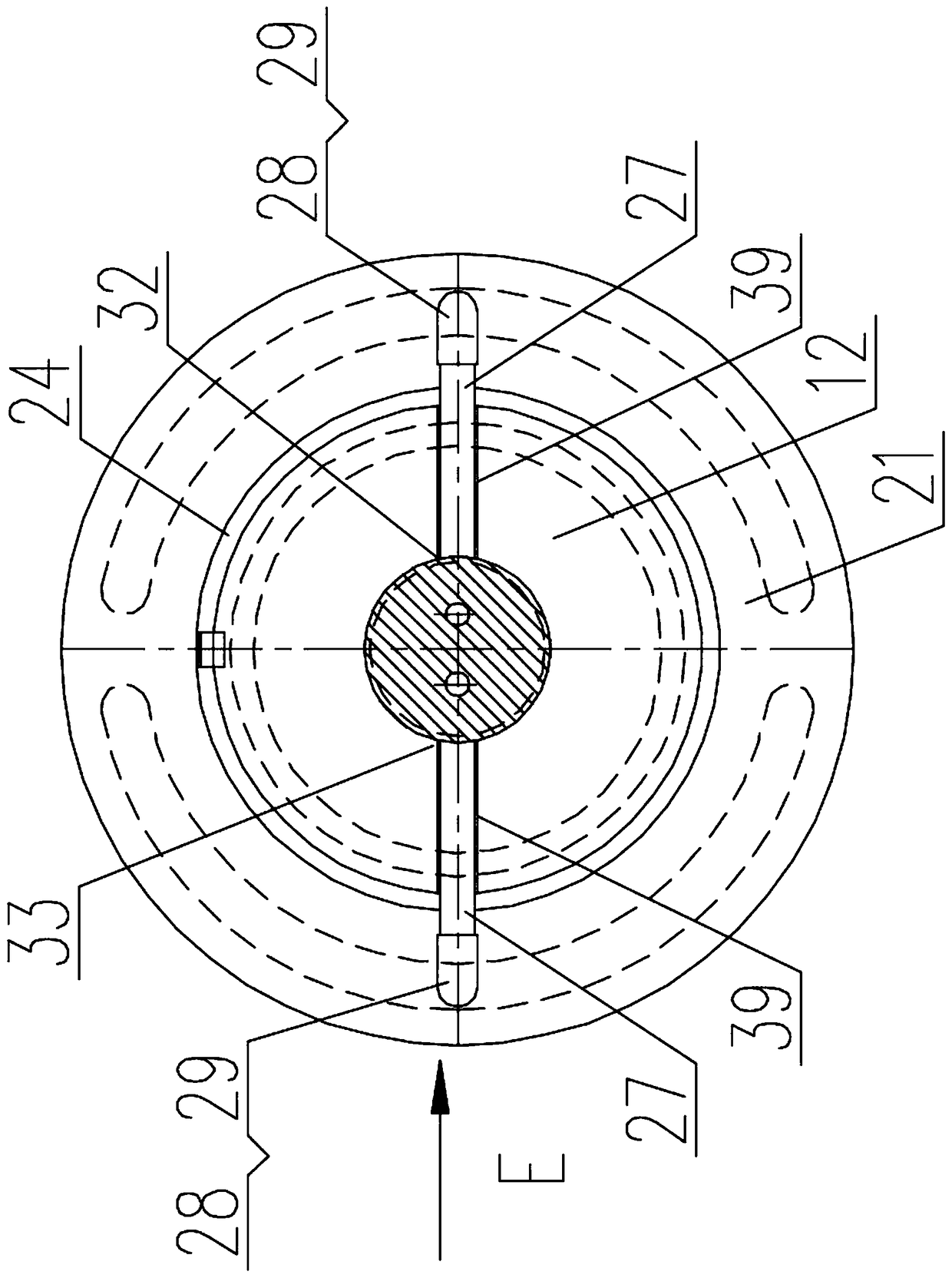

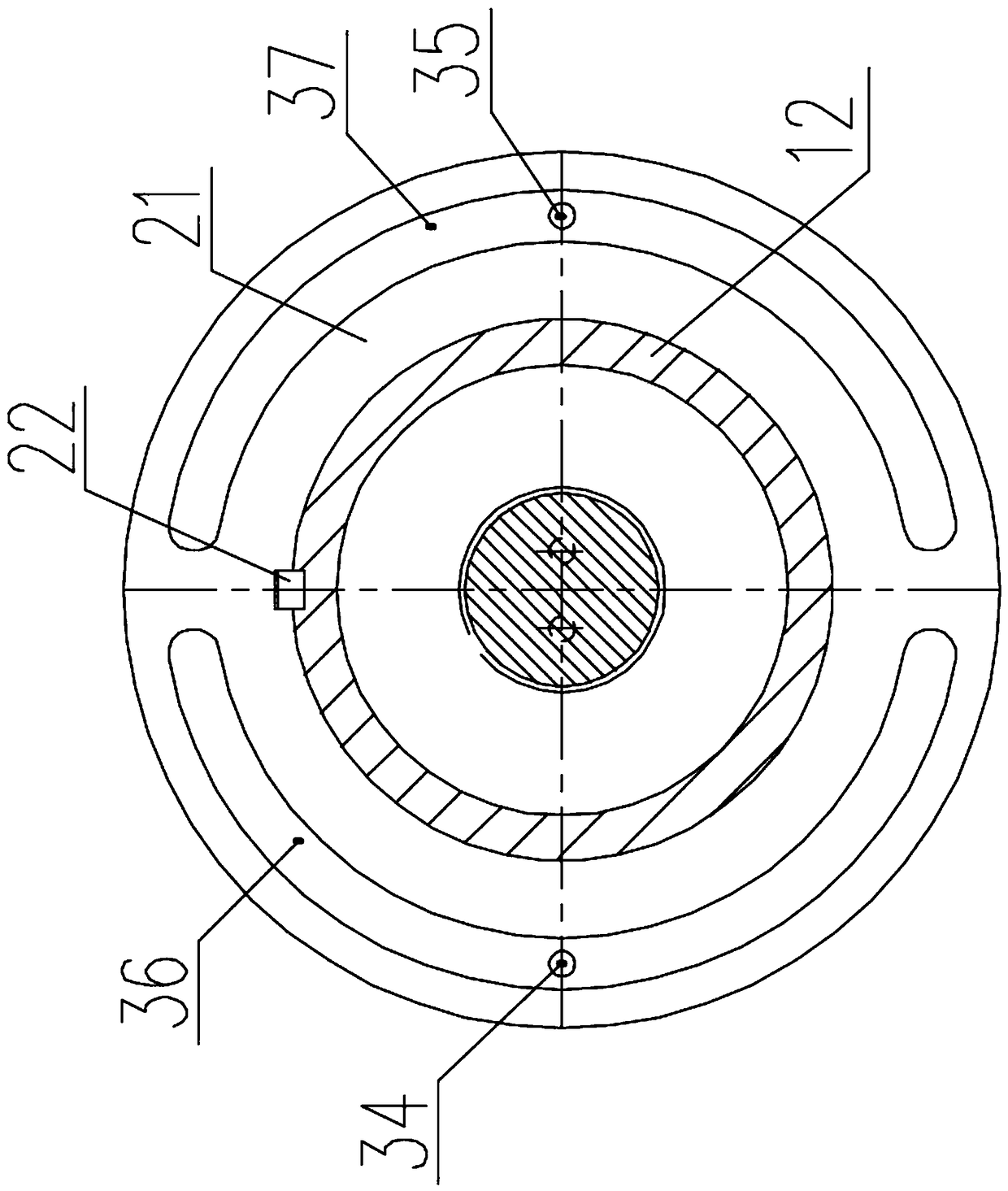

[0031] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The direction to the right of the front is described as the front).

[0032] Such as figure 1As shown, the speed-adjustable hydraulic axial plunger type transmission drum includes a cylinder body 2, a web plate 4, and a drum shaft 25; the outer surface of the cylinder body 2 is covered with a rubber layer 1, and two web plates 4 are fixed symmetrically front and back. Inside the cylinder body 2, at least one web plate 4 is fixedly installed in the interior of the cylinder body 2 through the web plate mounting bolts 3. The center position of the web plate 4 is provided with a bearing seat structure, and the bearing seat structure is provided with a bearing 10 inside and outside A bearing end cover 5 is provided, and a dust-proof seal 9 is also provided inside the bearing end cover 5. The bearing end cover 5 is fixedly installed on the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com