Patents

Literature

61results about How to "Uniform rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

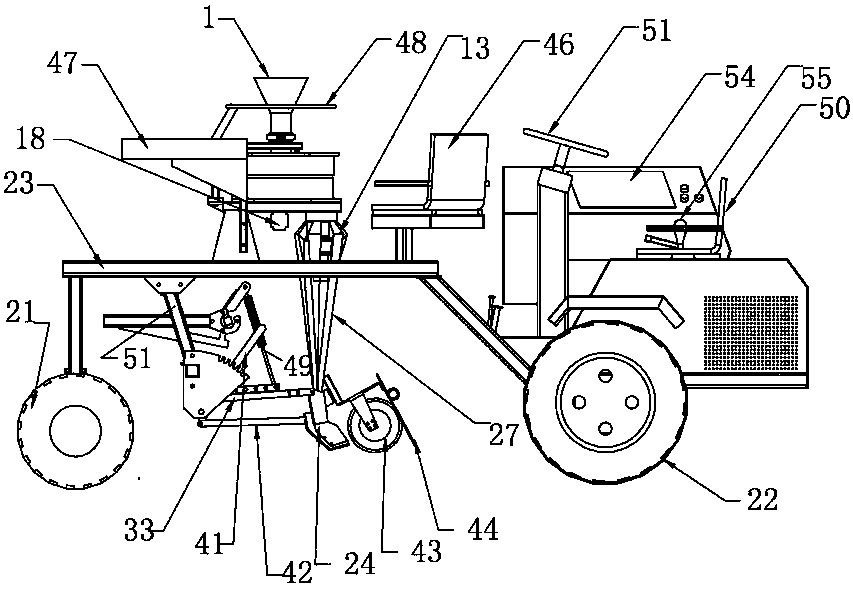

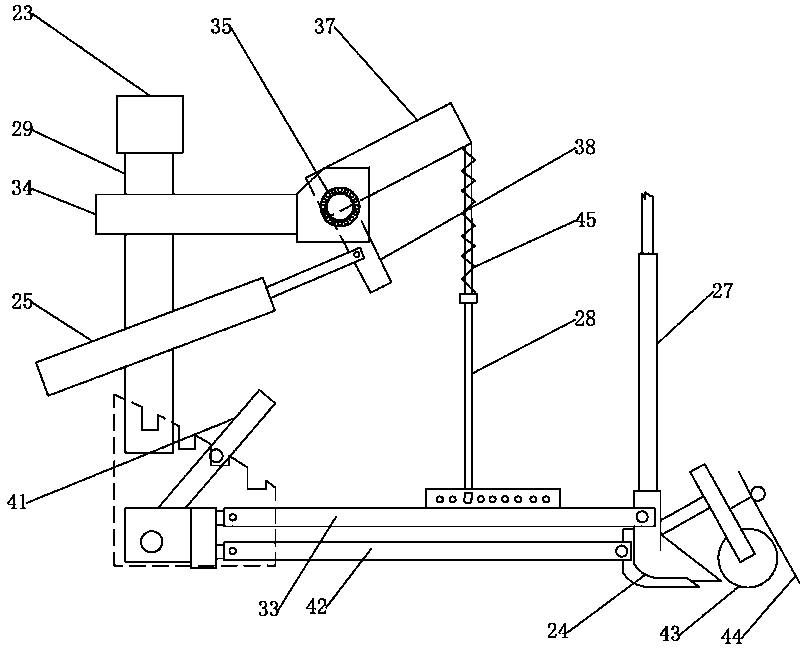

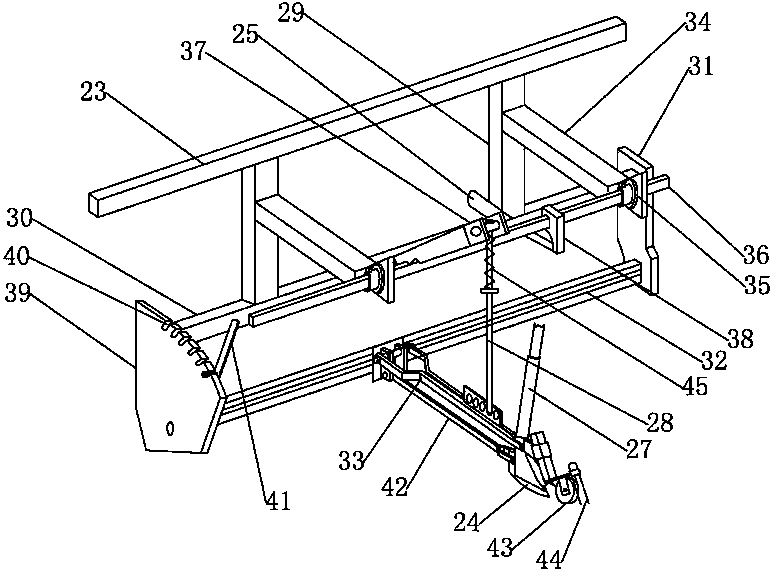

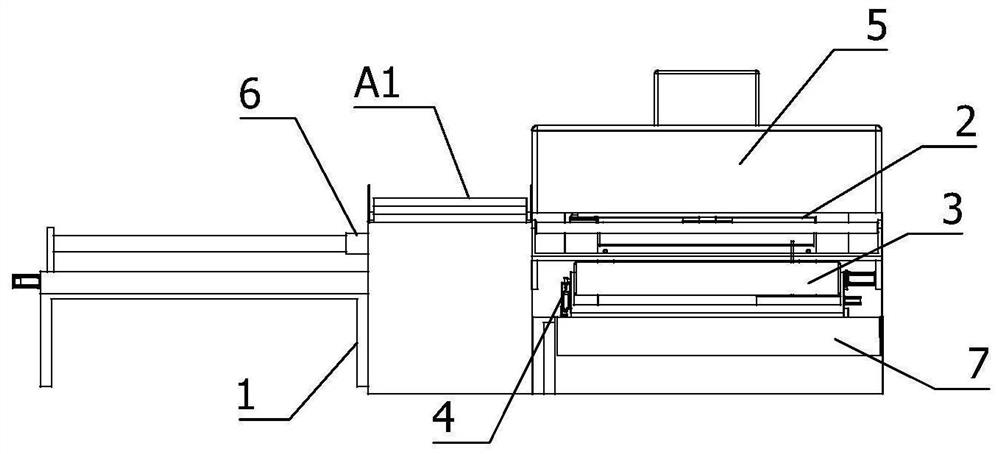

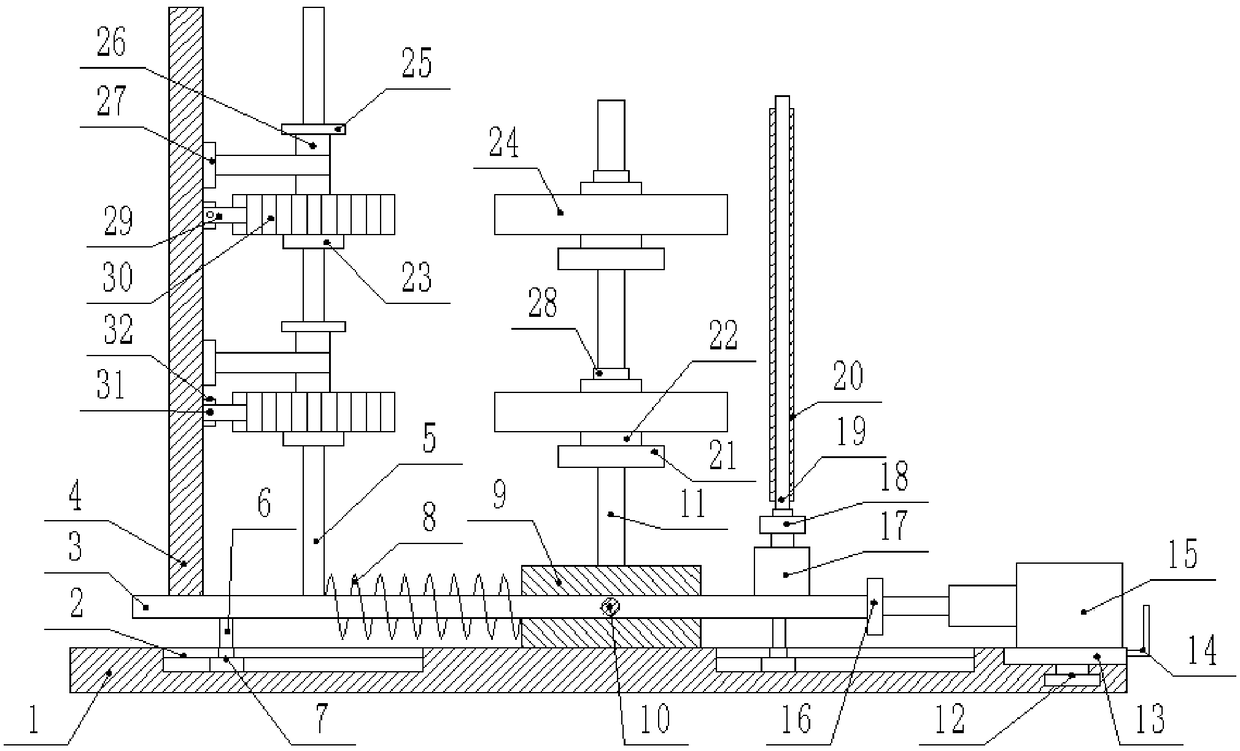

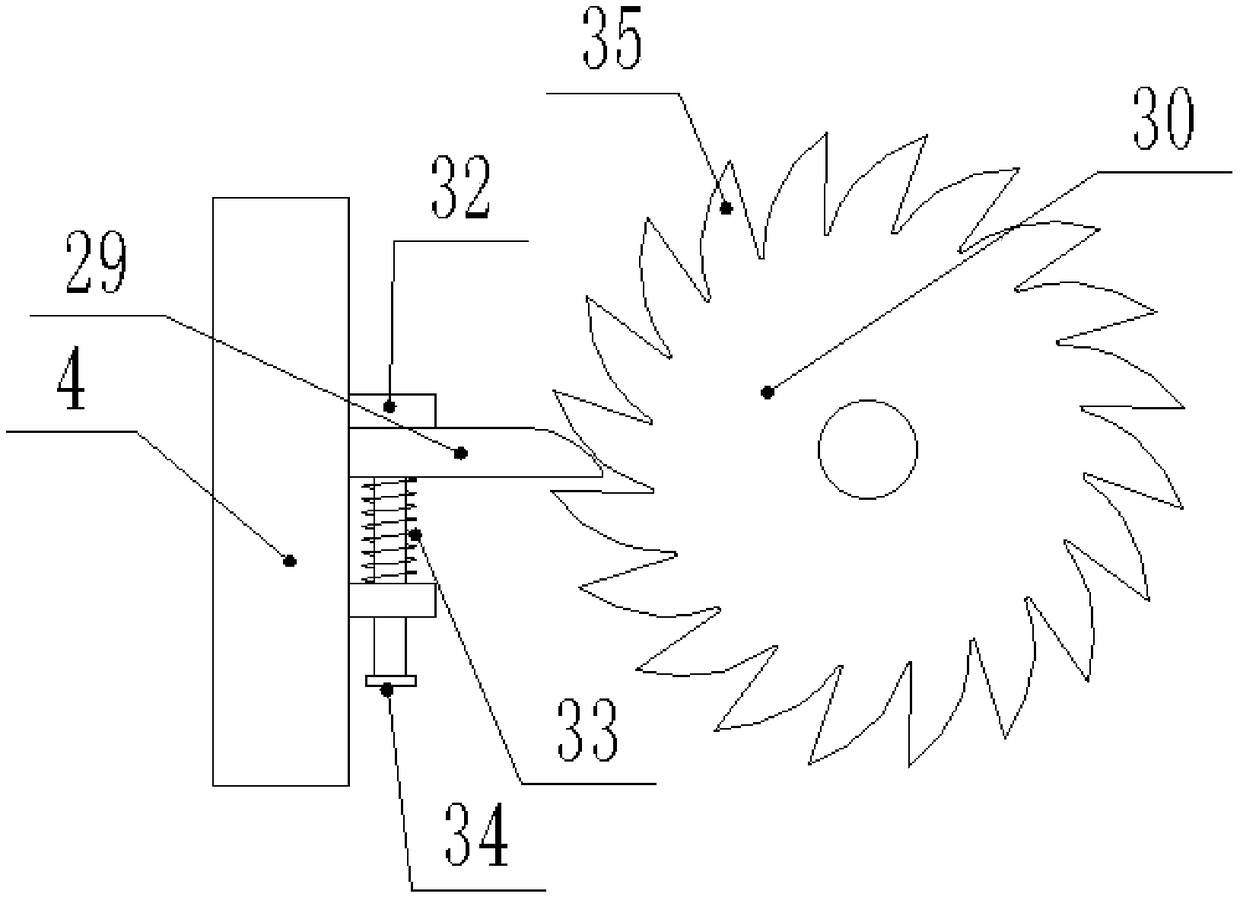

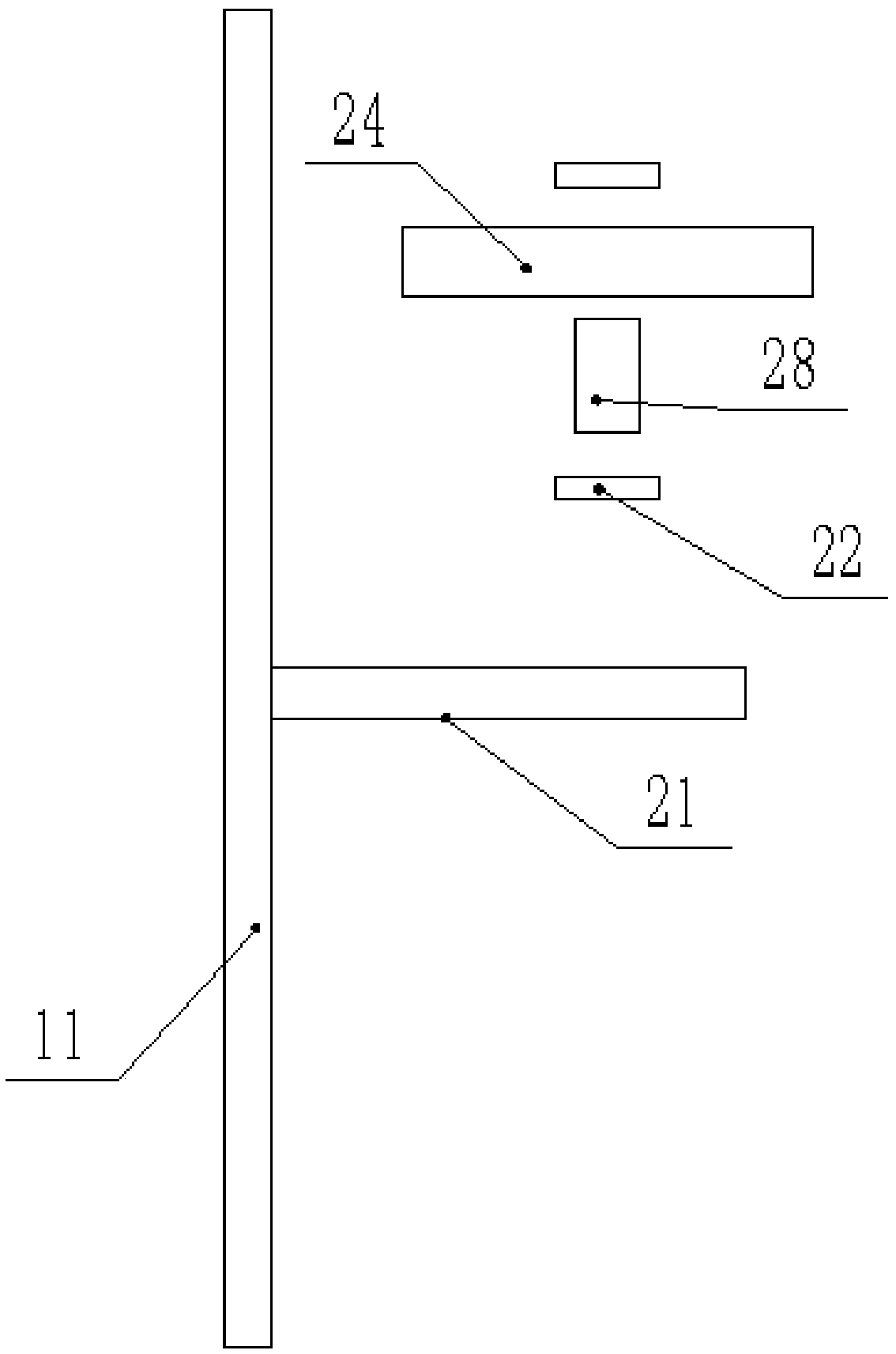

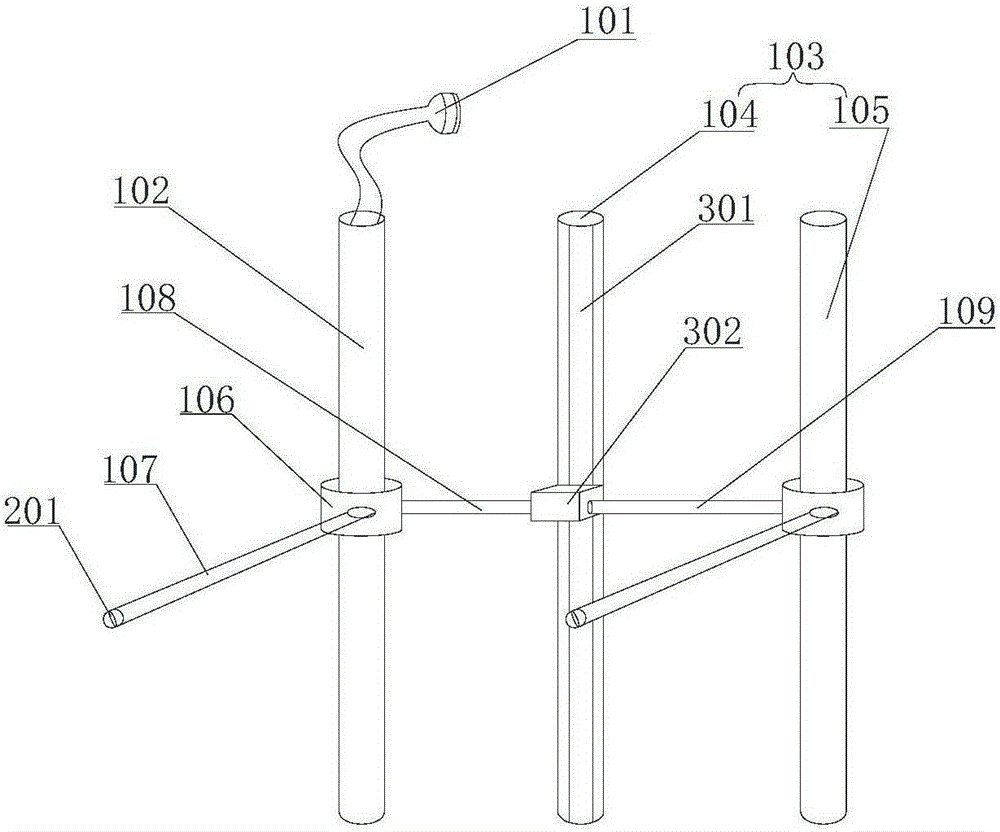

Electric self-propelled numerical-control plot drill seeder

ActiveCN104012222APrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlSeeder

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

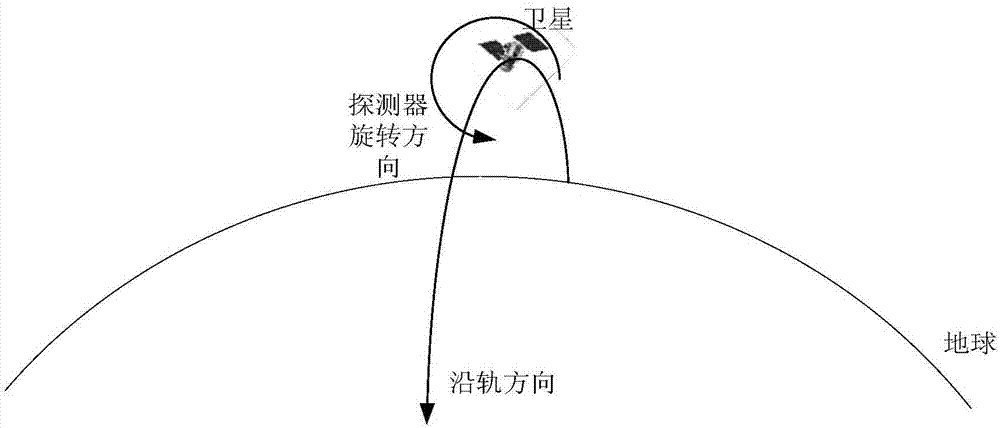

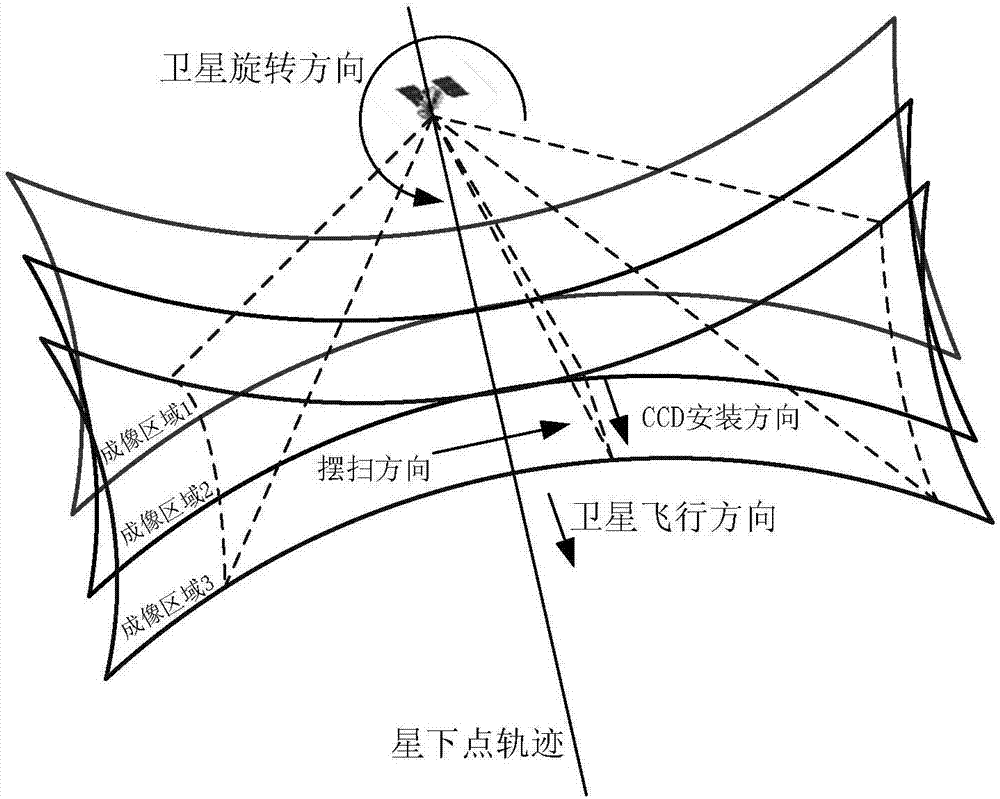

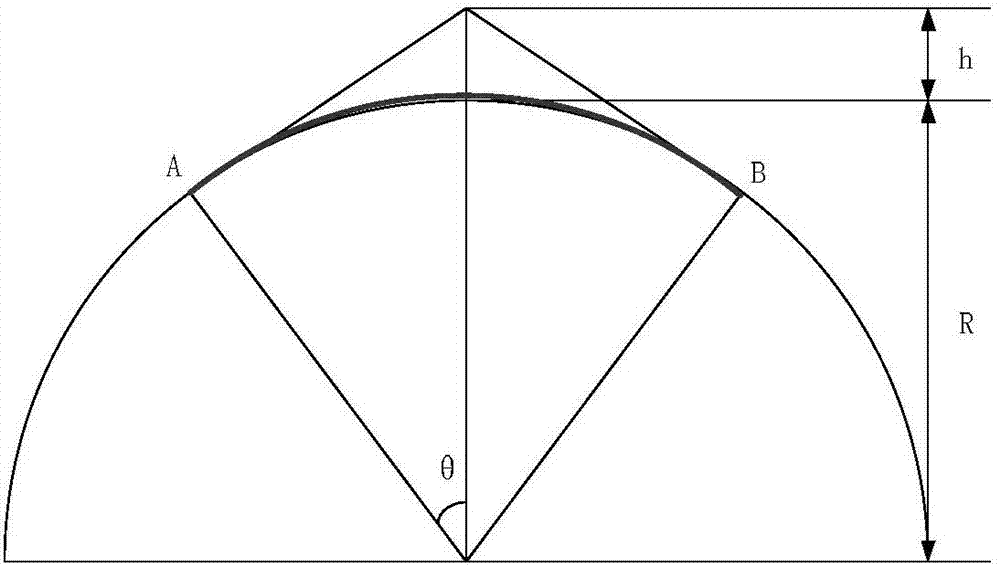

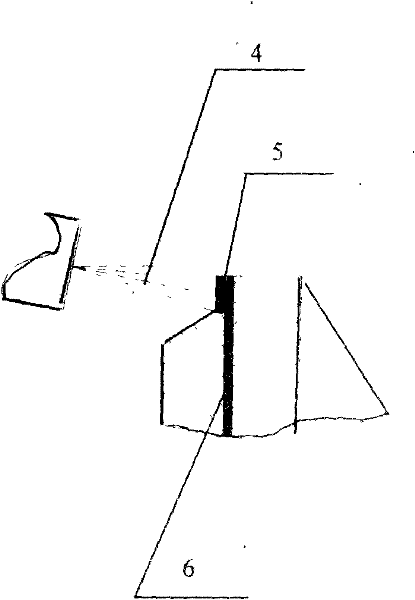

Quick rotary ultra-width pendular satellite imaging method

ActiveCN107152926ARealize ultra-large width swing-scan imagingIncrease coverageCosmonautic vehiclesCosmonautic partsFlight directionImage resolution

The invention discloses a quick rotary ultra-width pendular satellite imaging method, and relates to ultra-width pendular imaging methods. By the aid of the quick rotary ultra-width pendular satellite imaging method, the problems of incapability of meeting ultra-width imaging requirements on ground regions by conventional imaging methods and incapability of carrying out seamless splicing imaging on imaging regions of two adjacent orbits of a single satellite can be solved. The quick rotary ultra-width pendular satellite imaging method includes steps of firstly, computing the widths L<5> perpendicular to orbits; secondly, computing the widths L<1> in flight directions; thirdly, determining whether critical values of distances L2 of the centers of the optical axes of detectors on tracks of sub-satellite points on earth surfaces are the widths L<1> of the flight directions or not; fourthly, computing the spinning speeds of the detectors along the directions of the orbits; fifthly, computing corresponding resolution ratios A<c> of the detectors during ultra-width imaging under various orbit conditions; sixthly, computing horizontal frequencies F of CCD (charge coupled devices); seventhly, computing superposition distances L<6> among imaging regions of every two corresponding orbits and the like. The quick rotary ultra-width pendular satellite imaging method has the advantage that the quick rotary ultra-width pendular satellite imaging method can be applied to the field of ultra-width pendular imaging.

Owner:HARBIN INST OF TECH

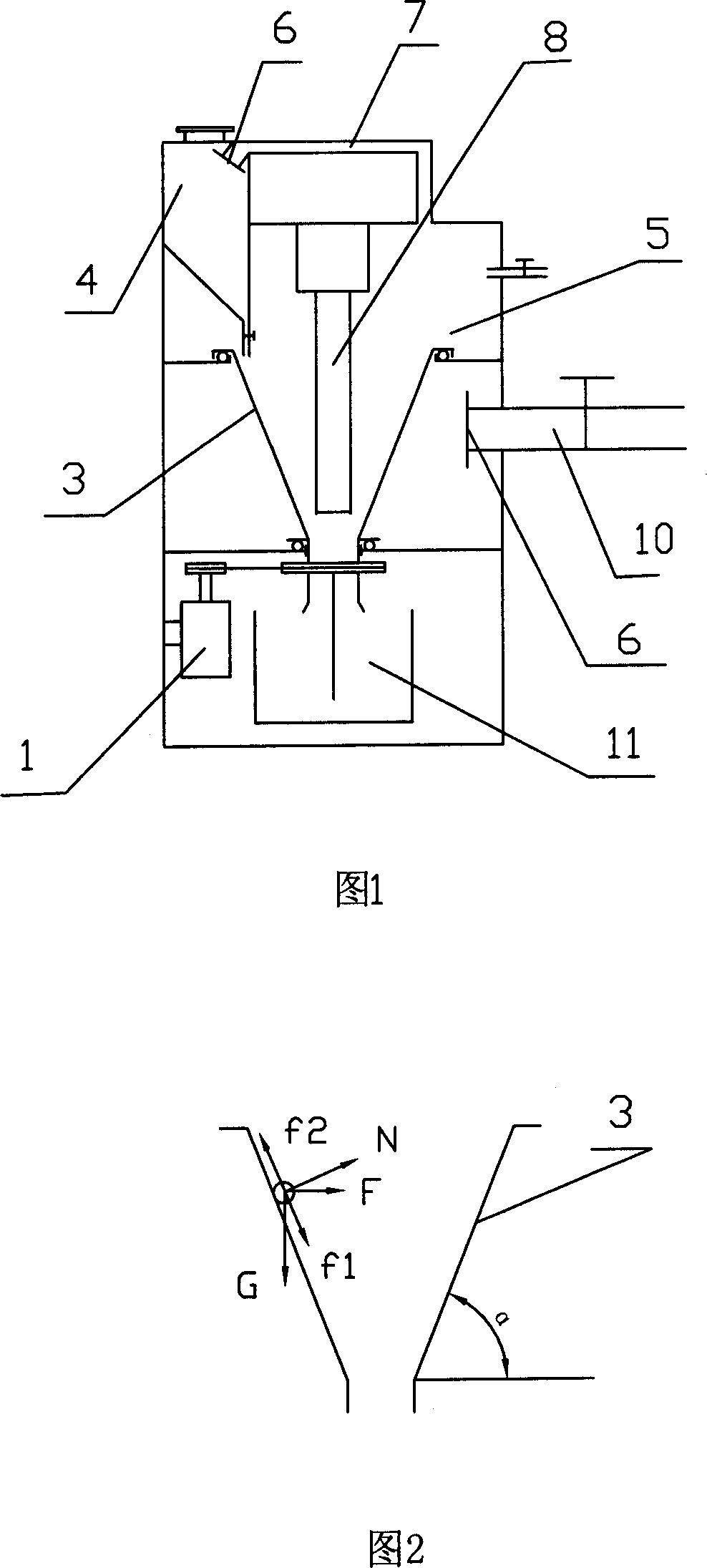

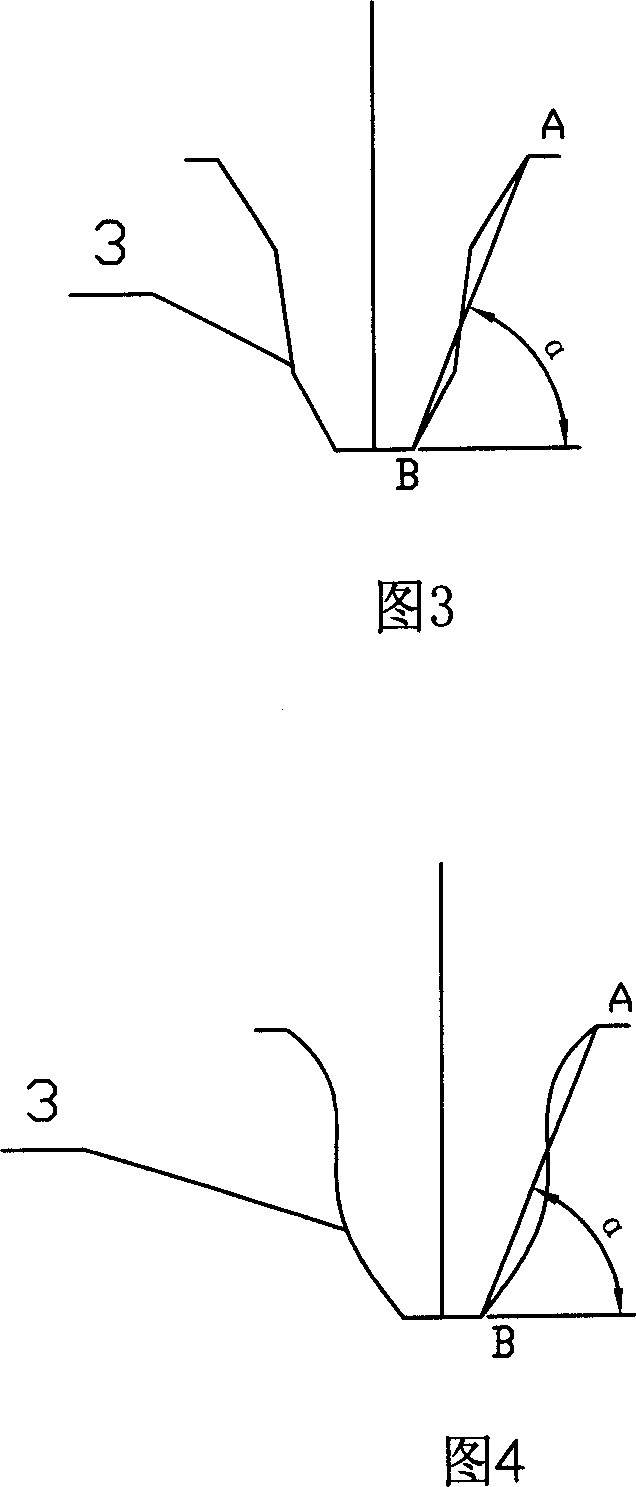

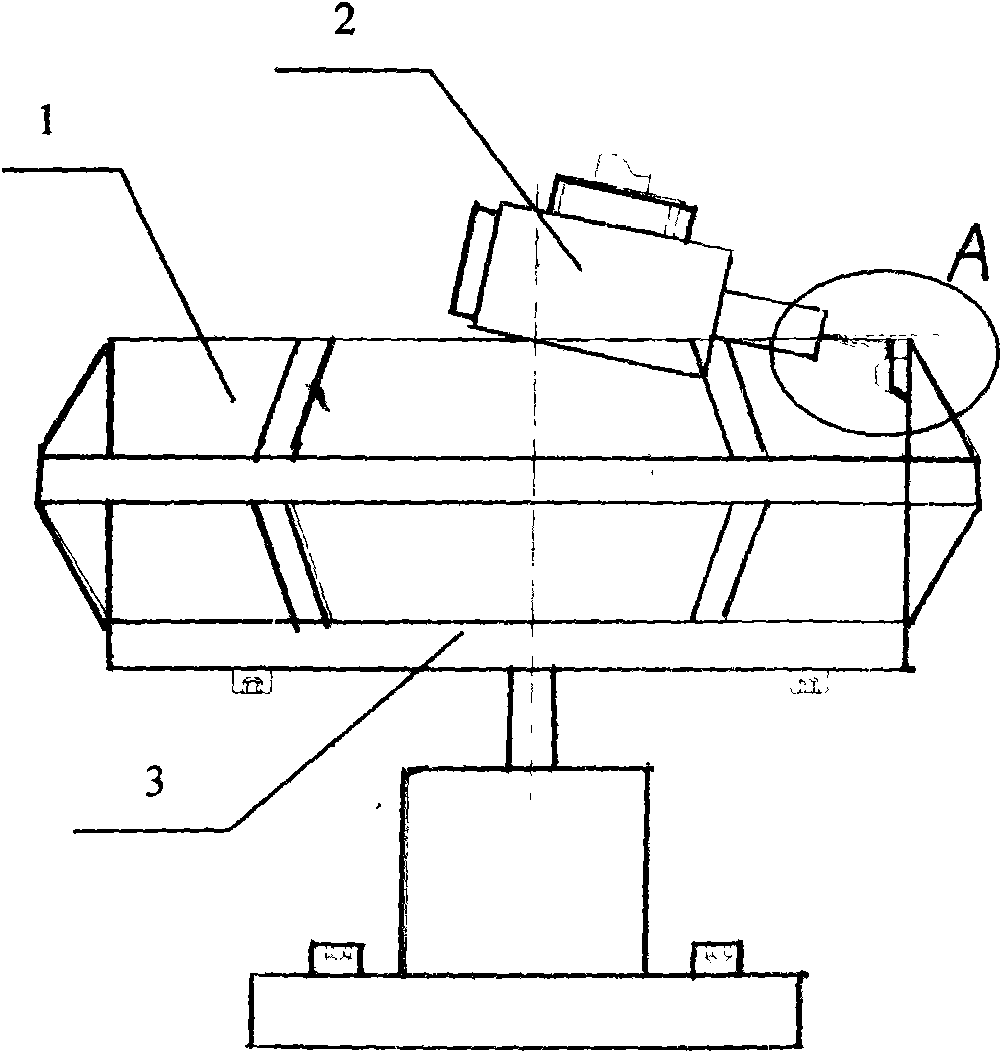

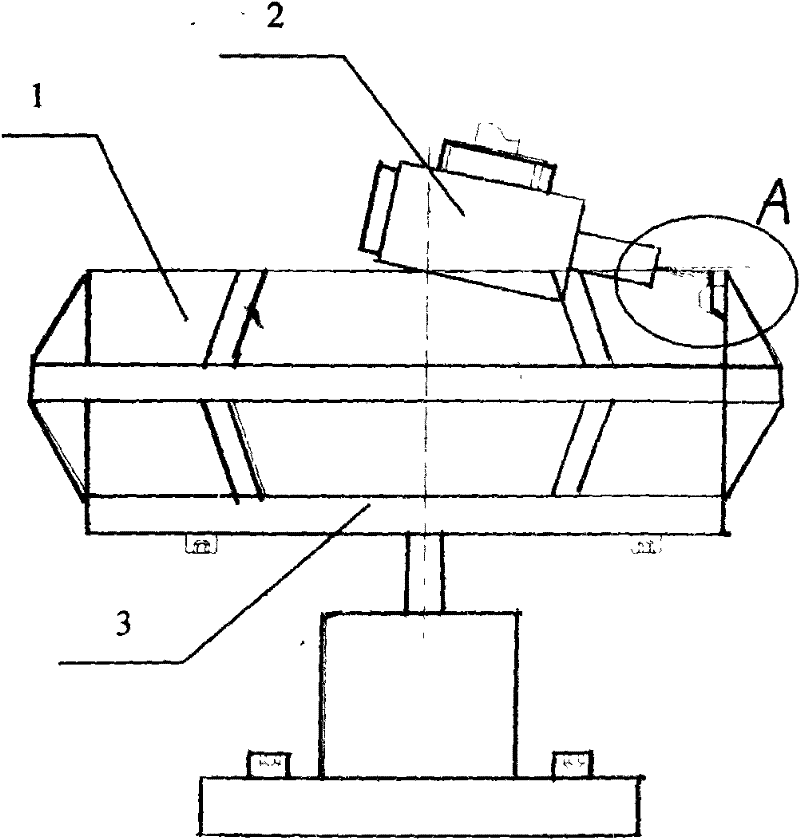

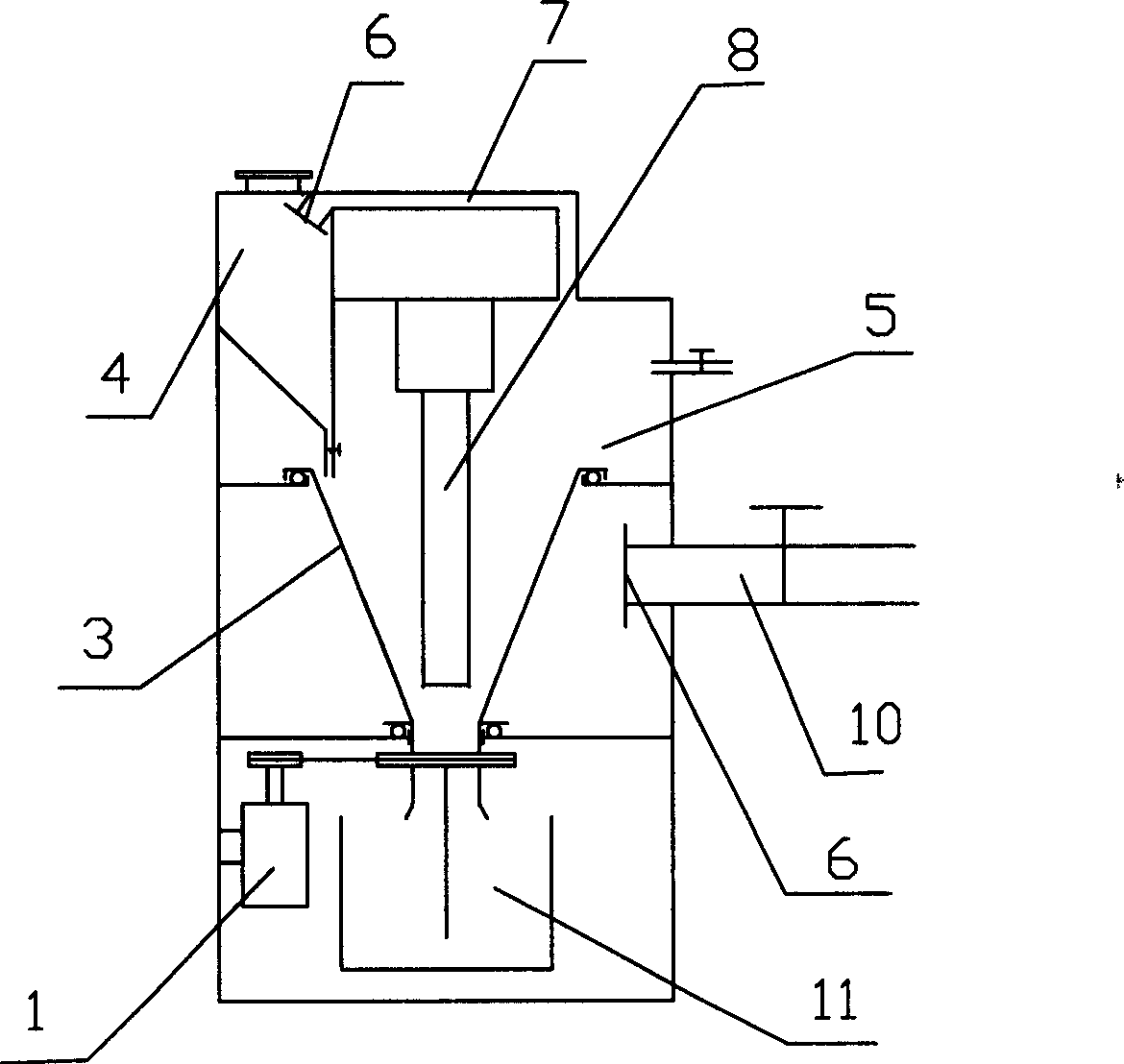

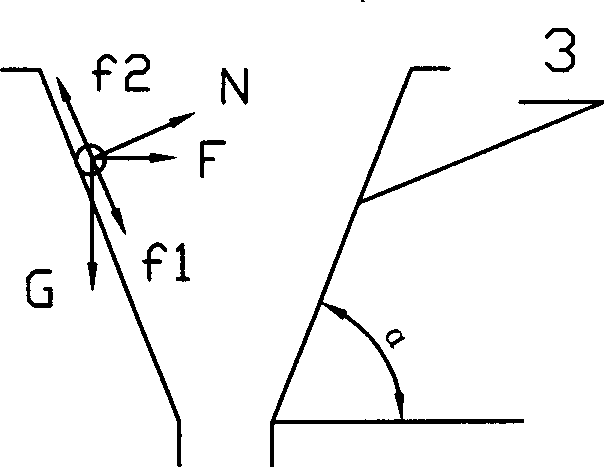

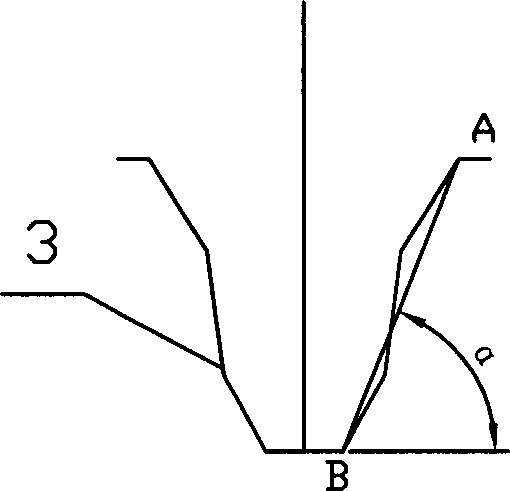

Technique for film plating on powder surface and equipment thereof

InactiveCN101082120AEasy flipWith speed control functionVacuum evaporation coatingSputtering coatingVacuum pumpingMetallurgy

The present invention is powder surface coating process and apparatus. During coating powder, the powder is made to fall spirally in a vacuum environment and a homogeneous cladding is formed on the surface of the powder. The apparatus for coating powder includes one vacuum chamber, a vacuum film coating source, and a vacuumizing system. Inside the vacuum chamber, there are one turned conic rotary hopper, one feeding chamber connected to the upper end of the hopper, and collecting chamber connected to its lower end. The vacuum film coating source mounted in the middle part inside the hopper has one speed adjustable motor for rotating the hopper. The present invention has great coating capacity and low running cost.

Owner:BYD CO LTD

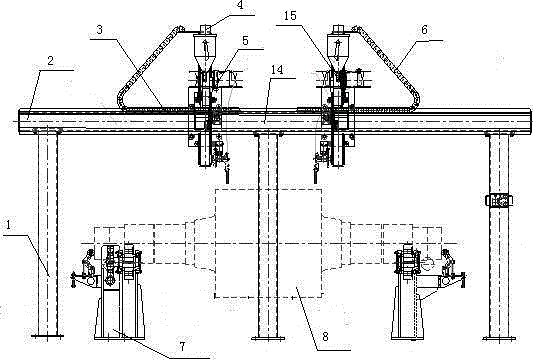

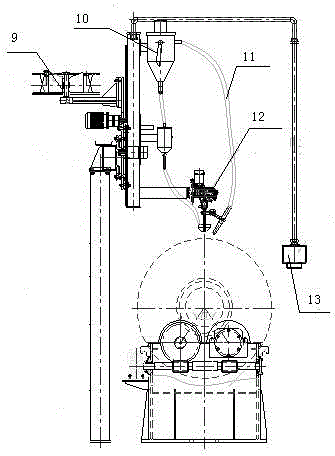

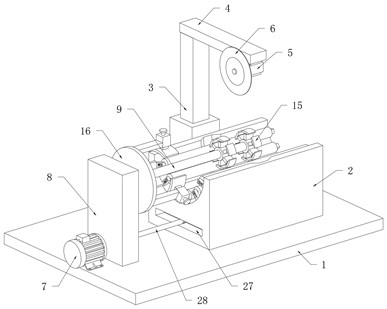

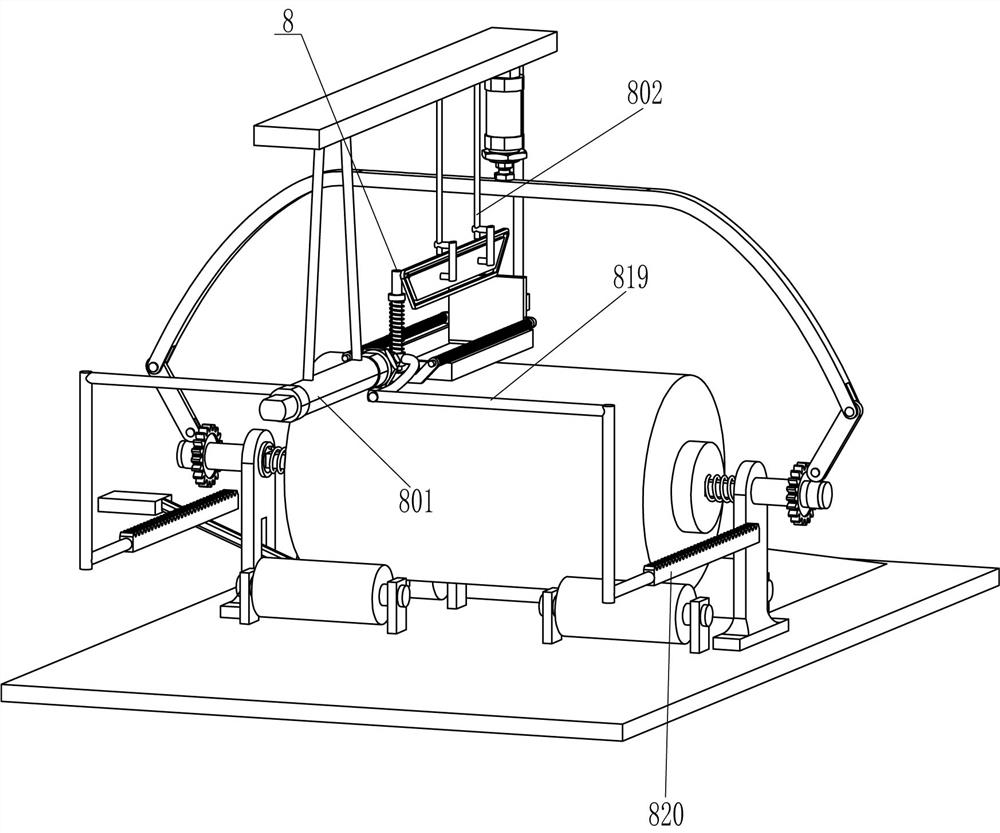

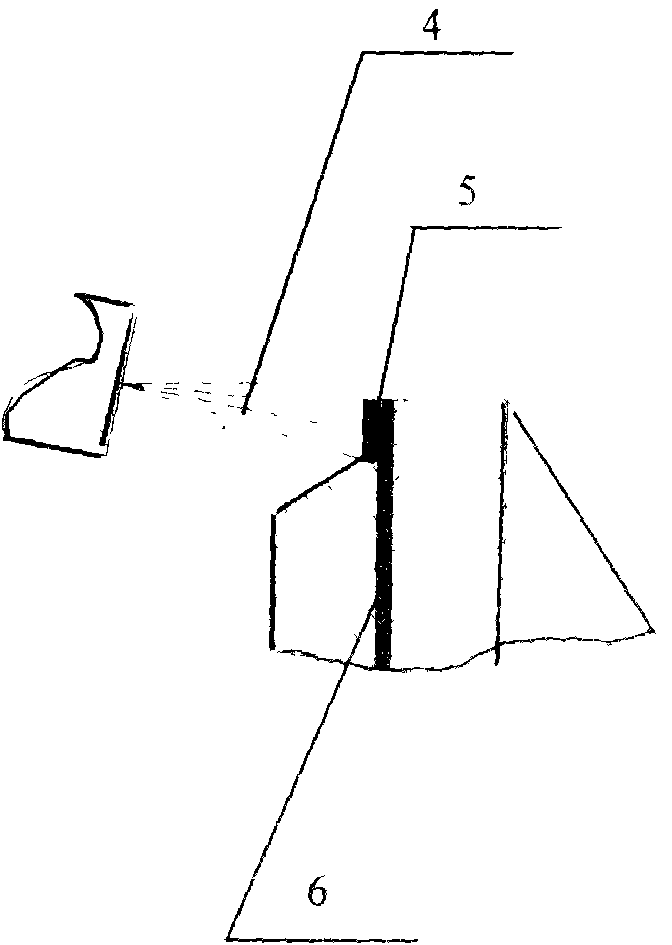

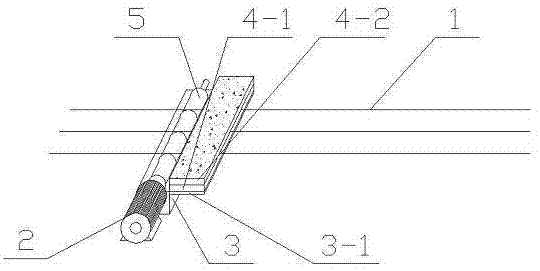

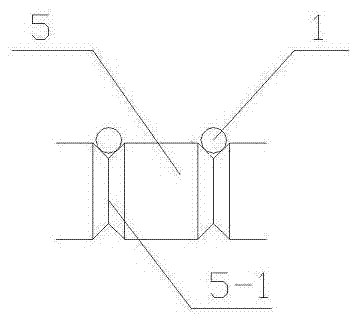

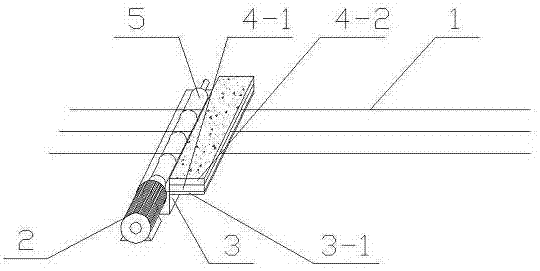

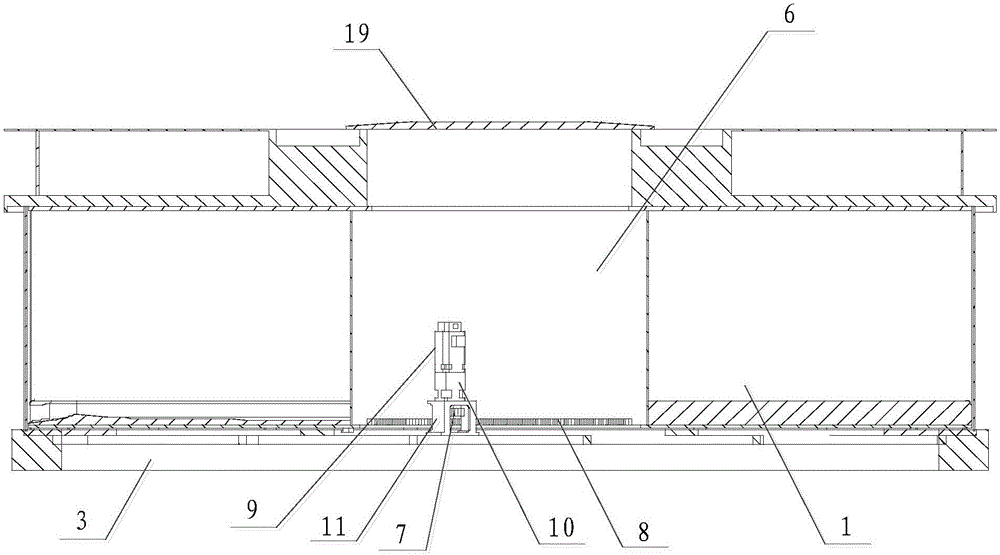

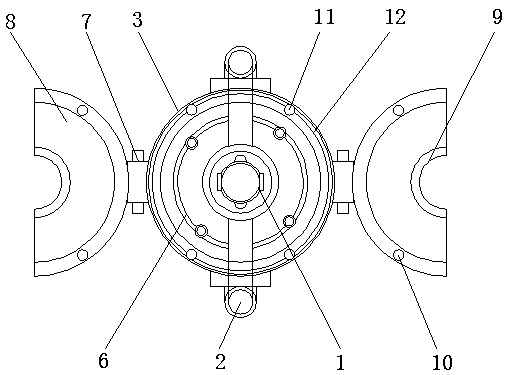

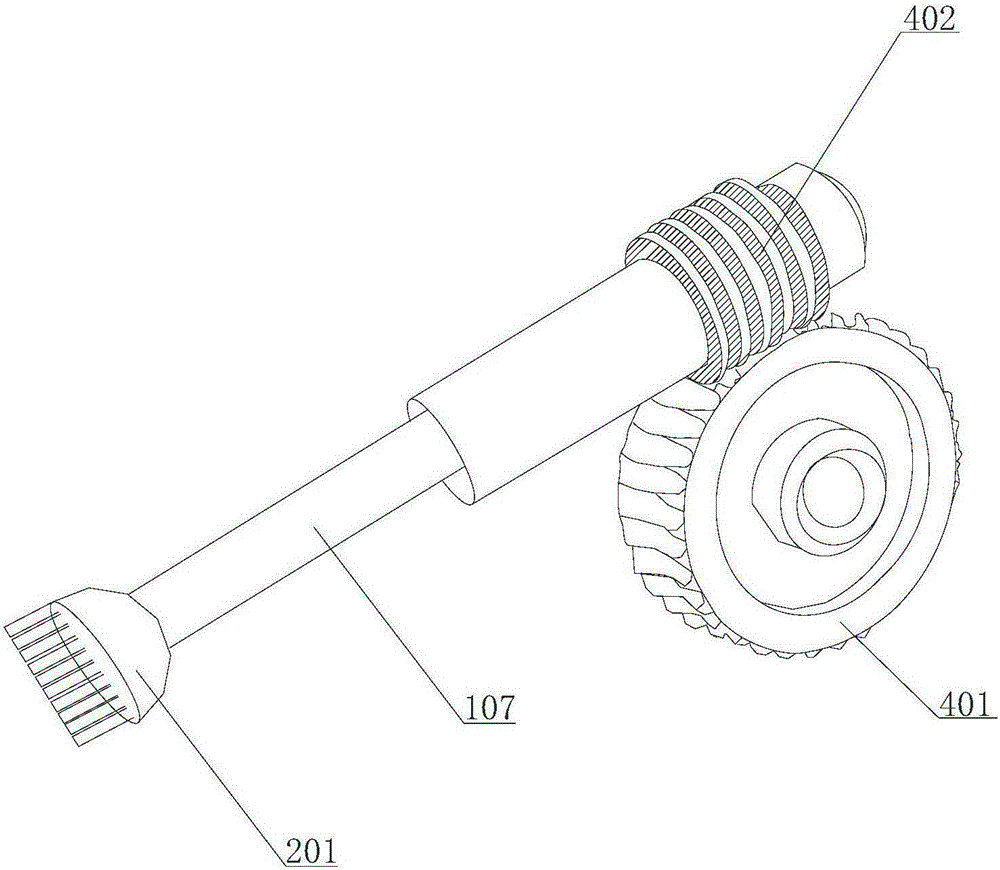

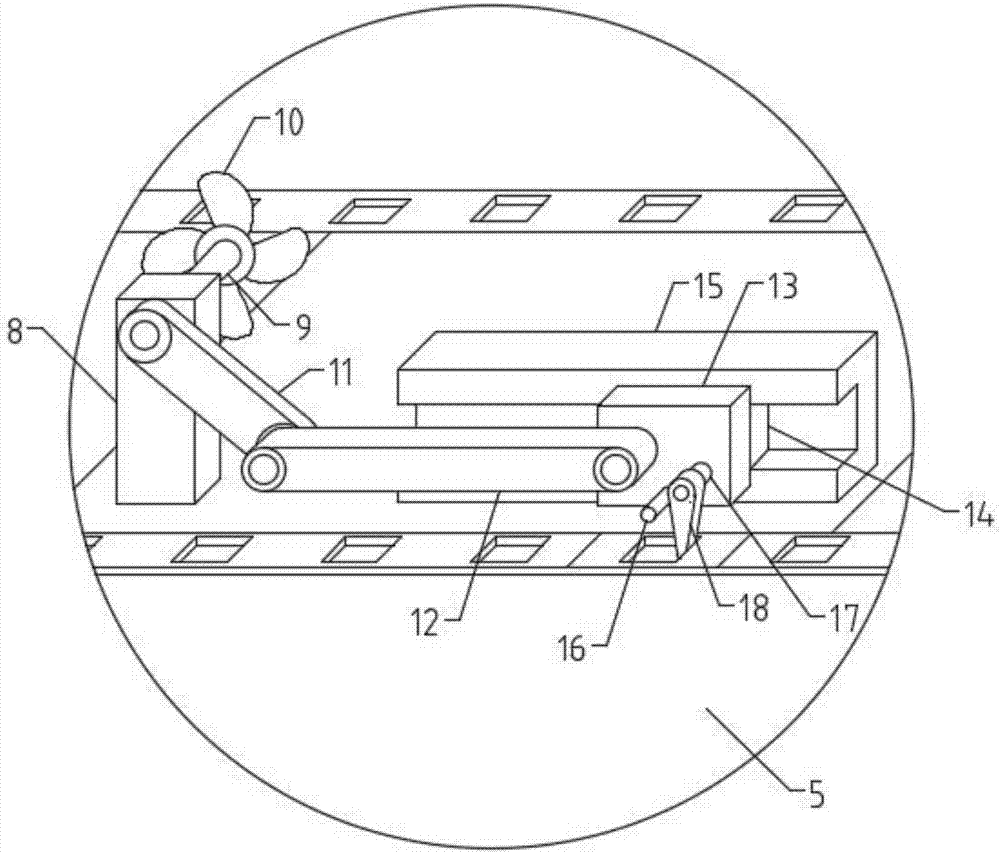

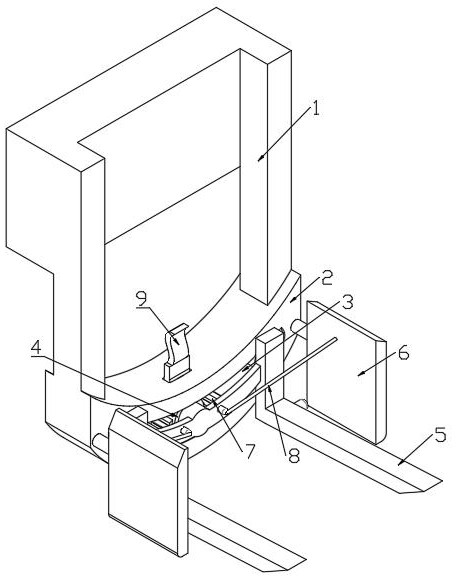

Special roll surfacing welding machine

InactiveCN104668722AUniform rotation speedSimple structureWelding/cutting auxillary devicesArc welding apparatusEngineeringSoldering gun

The invention belongs to the field of welding, and particularly relates to a special roll surfacing welding machine which comprises two welding mechanisms, a frame, two roller carriers and a welding gun moving mechanism. The welding mechanisms are mounted on the frame, the roller carriers are placed below the frame, and the welding mechanisms and the roller carriers are symmetric about the longitudinal center line of the frame. Each welding mechanism comprises a welding head, a flux hopper, a wire reel and a control box, wherein the flux hopper is connected with the welding head through a conveying pipe. The welding gun moving mechanism comprises a welding gun lifting mechanism, a welding gun travelling mechanism, a wiring drag chain and a travelling platform, wherein the travelling platform is arranged on the surface of the frame and connected with the welding gun lifting mechanism through the wiring drag chain. The special roll surfacing welding machine is simple in structure, low in cost and high in machining precision, and the rotating speed of a roll is uniform by the aid of the roller carriers.

Owner:CHENGDU HANYAN TECH

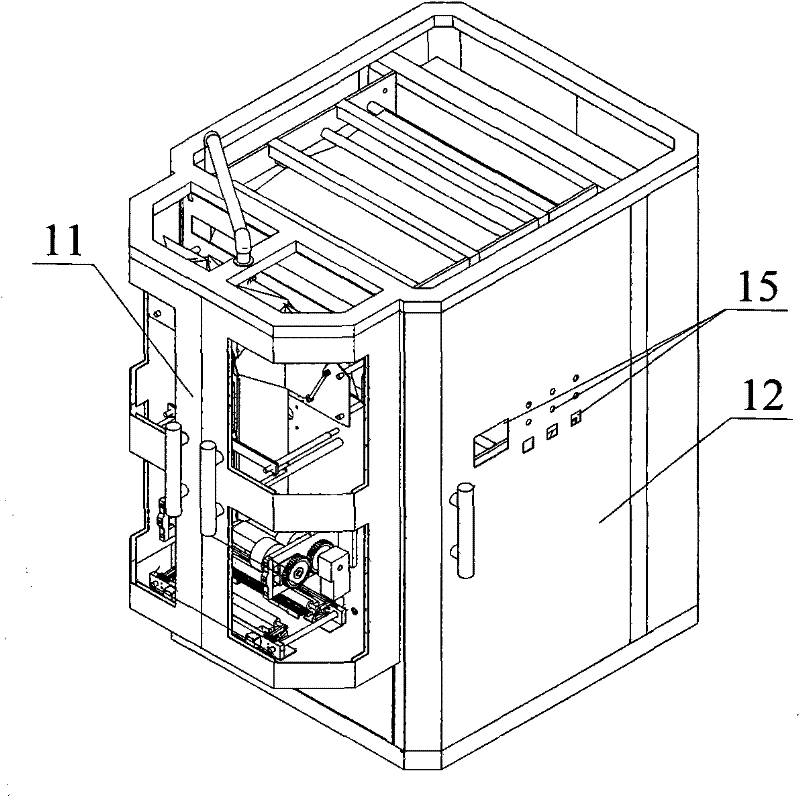

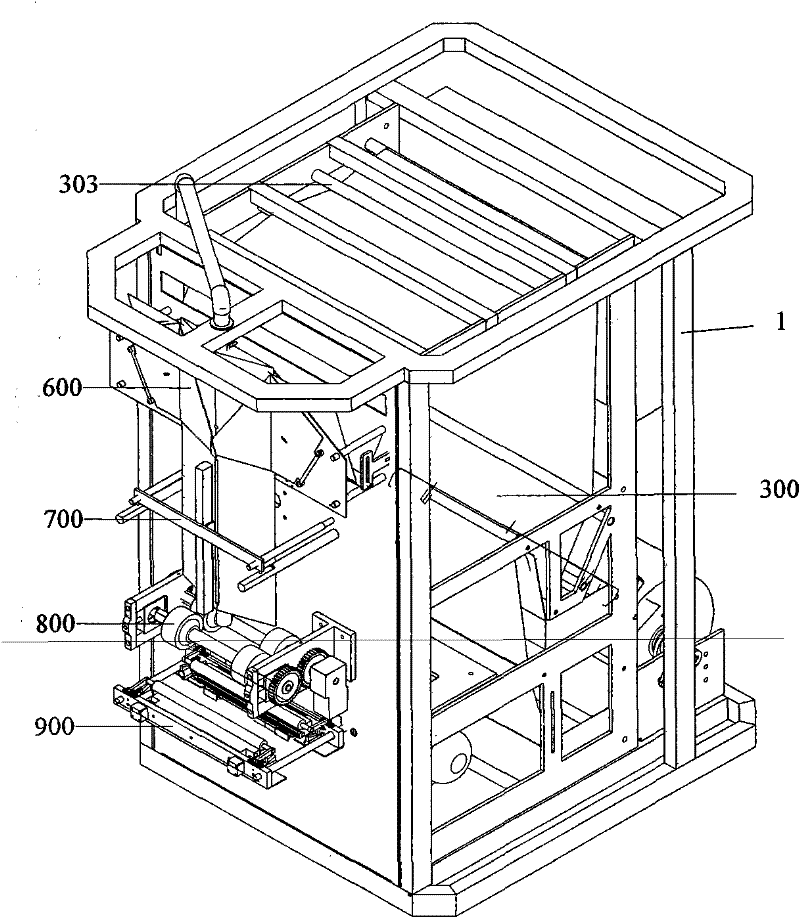

Automatic filling machine

ActiveCN102442628ANo manual operationRealize automatic controlBottle-handling machinesEngineeringElectric control

The invention discloses an automatic filling machine, which comprises a machine frame and an electric control device. A film rolling device for storing and releasing a film, a film connecting device for connecting the film, a disinfecting and cleaning device for disinfecting and cleaning the pulled film, a filling device for filling liquid in a film bag, a forming device for turning and rolling the film into a cylindrical structure, a vertical sealing device for vertically piecing and sealing the cylindrical film, a film pulling device for pulling the film to move and a transverse closing andcutting device for transversely closing and cutting the cylindrical film are arranged on the machine frame in turn. The automatic filling machine provided by the invention is high in production efficiency, lower in cost and high in automation degree.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

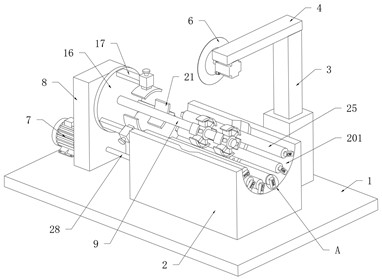

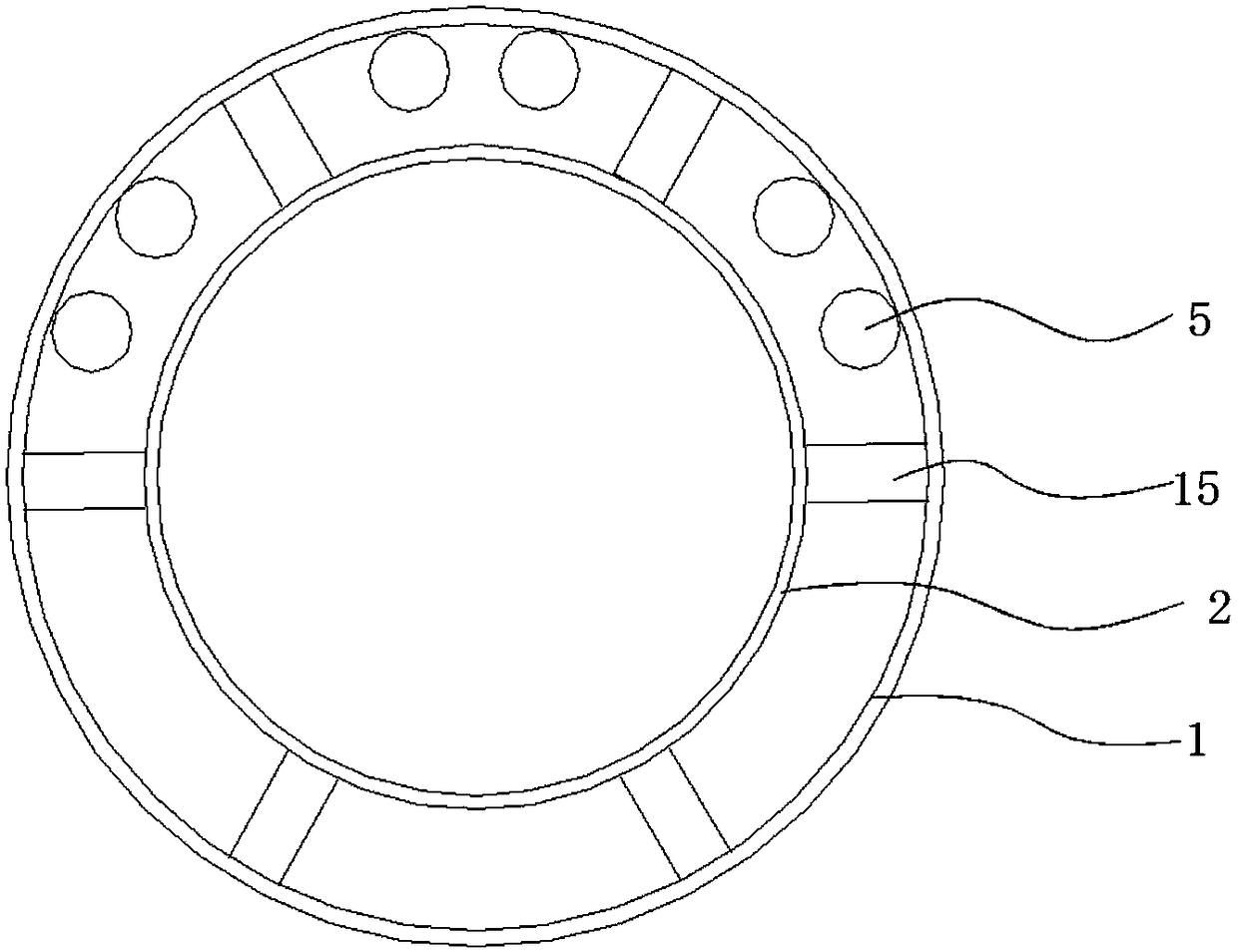

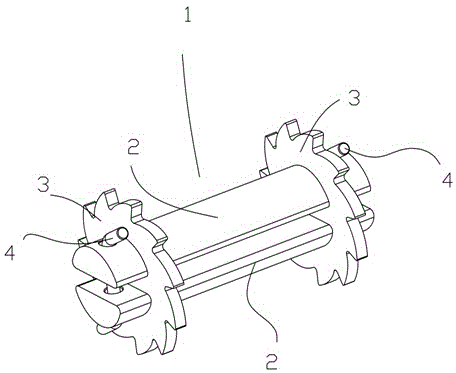

Anti-deformation metal pipe cutting device

ActiveCN113510296AIncrease clamping and fixing strengthExtended service lifeTube shearing machinesMaintainance and safety accessoriesElectric machineryStructural engineering

The invention discloses an anti-deformation metal pipe cutting device which comprises a base. A cutting table is fixedly connected onto the base; a second motor is fixedly connected to the side, away from the cutting table, of the base; a gearbox is fixedly connected to the position, close to the second motor, of the cutting table; an output shaft of the second motor is connected with the gearbox; a main shaft is rotationally connected onto the outer wall of the upper end of the gearbox; a clamping and fixing device is arranged on the main shaft; and a cutting groove with a semi-arc-shaped section is formed in the cutting table. According to the equipment, the clamping and fixing strength of a metal pipe is improved, so that the cutting stability is improved; the inner walls, located on the two sides of a cutting opening, of the metal pipe can be supported during cutting, so that the cutting opening is prevented from deforming; the rotating speed of the metal pipe is controlled to be balanced, so that cutting is more neat, and damage to a cutting blade is greatly reduced; and water spraying cooling treatment is added to improve the cutting quality and prolong the service life of the blade.

Owner:南通赫爵金属制品有限公司

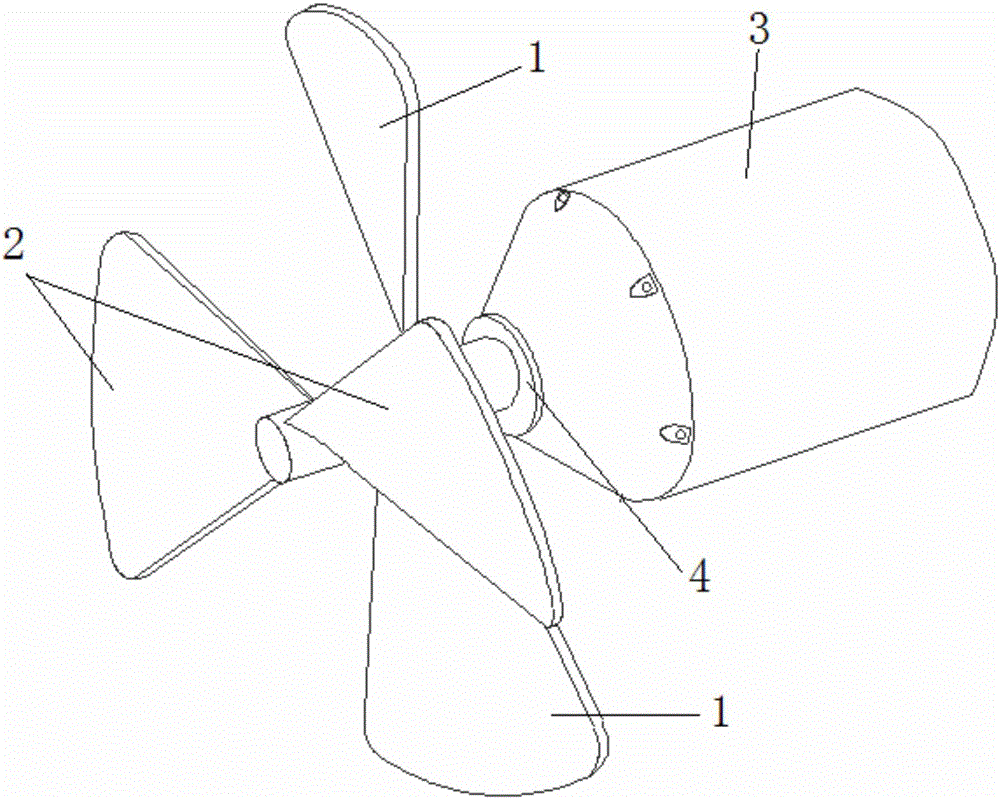

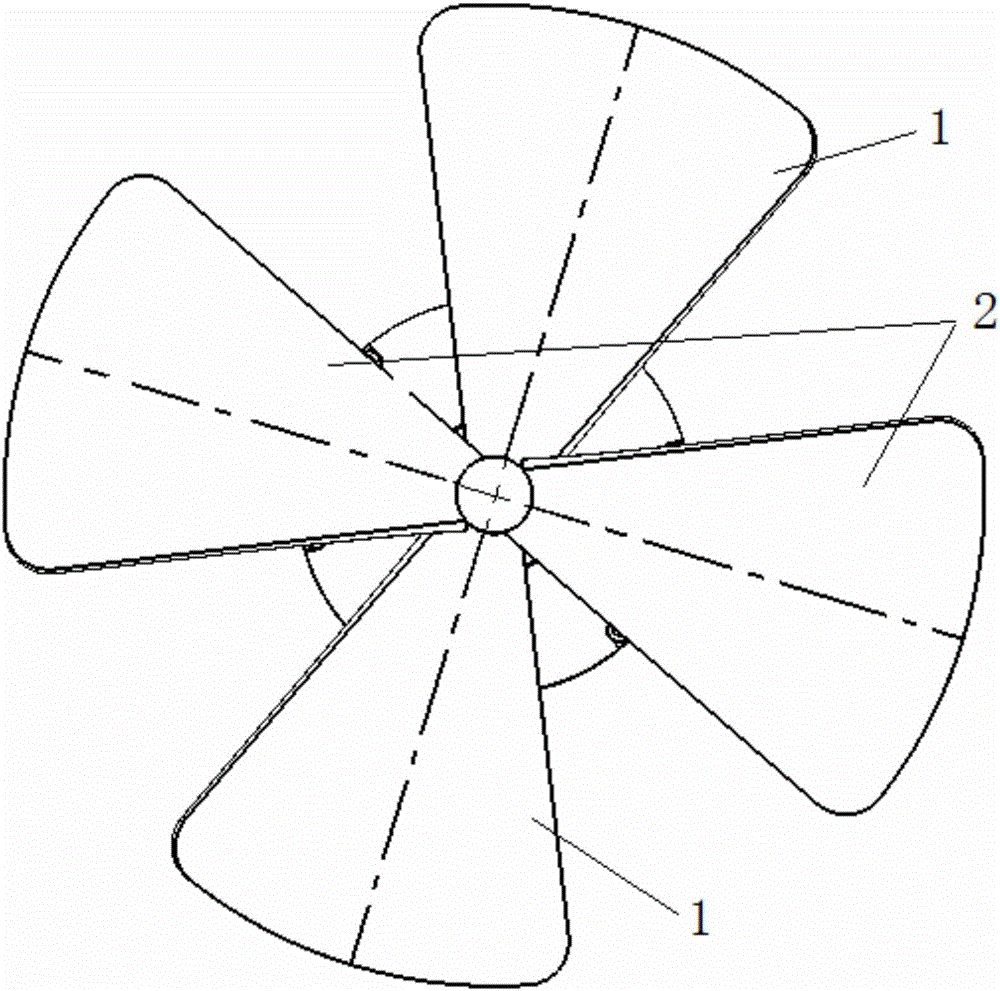

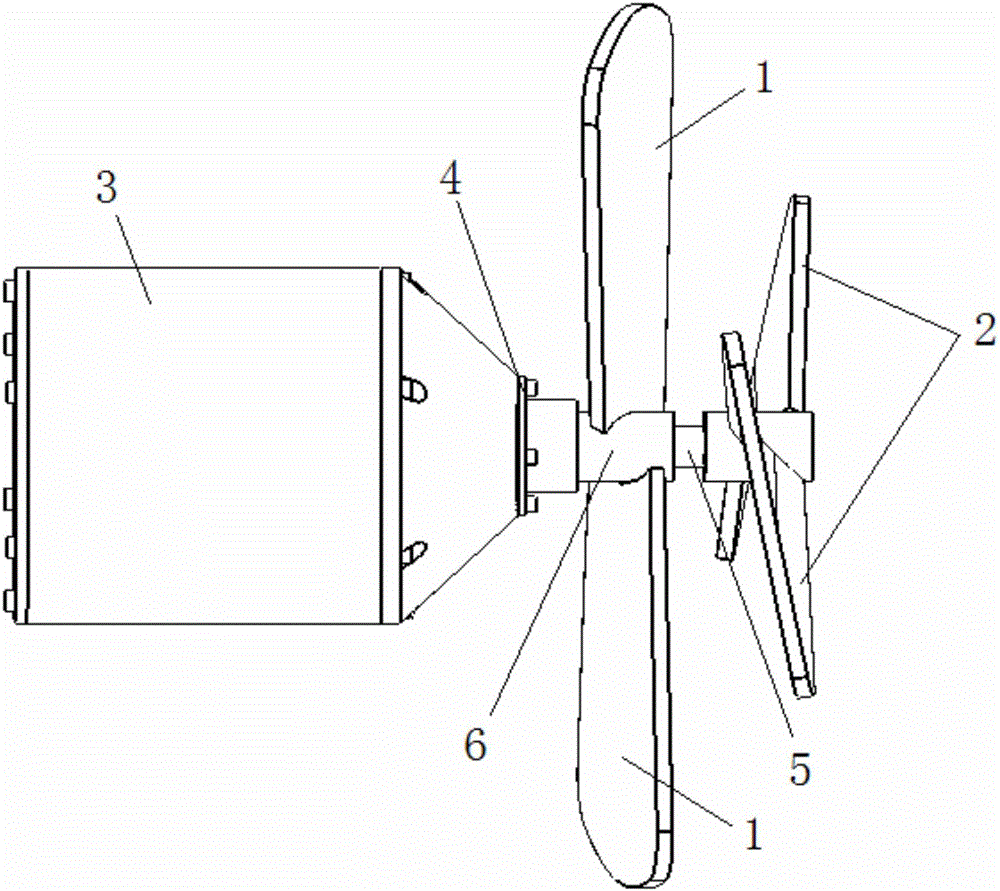

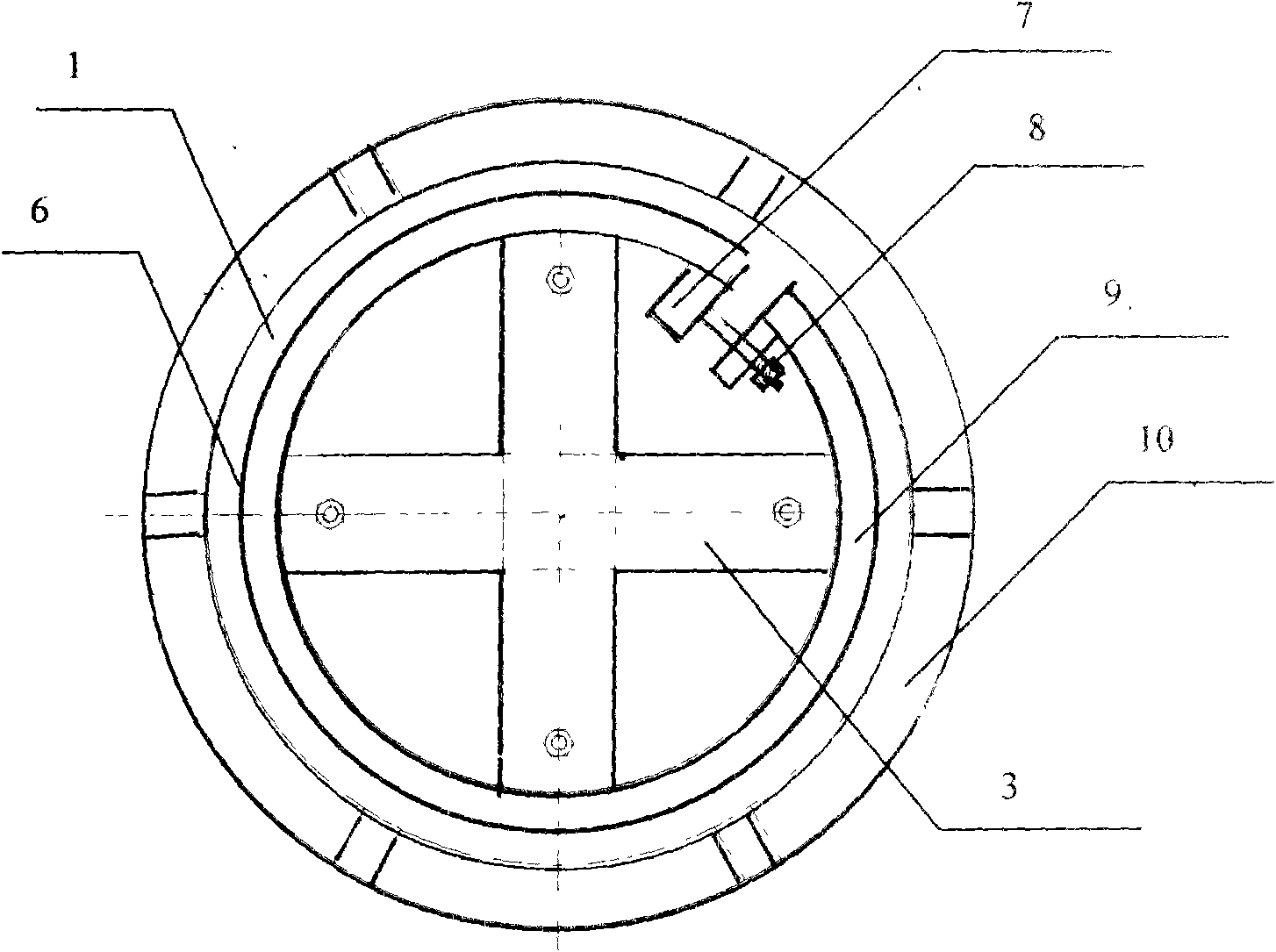

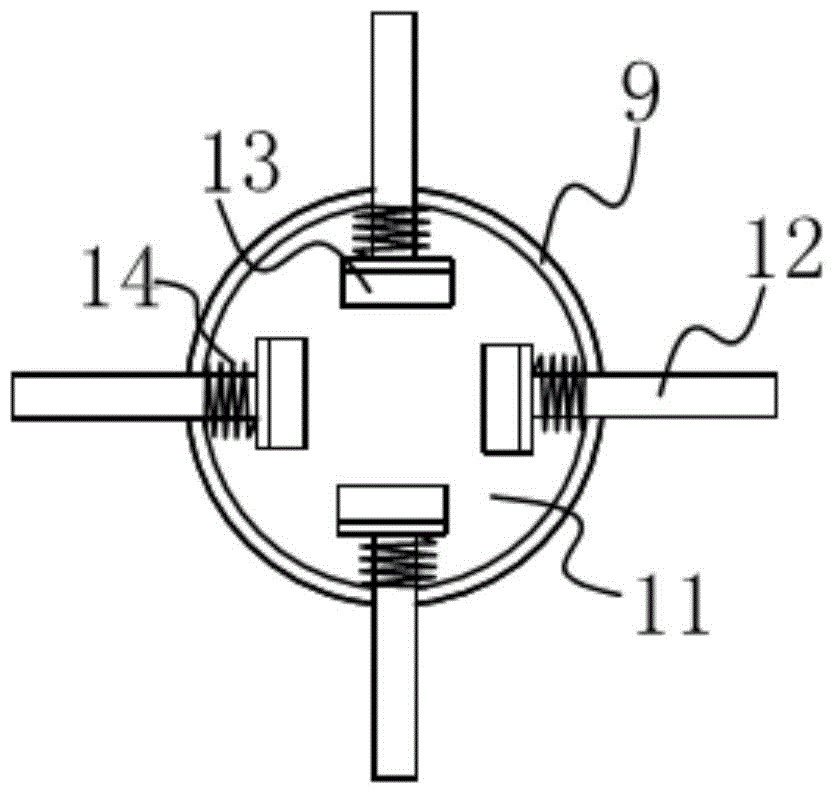

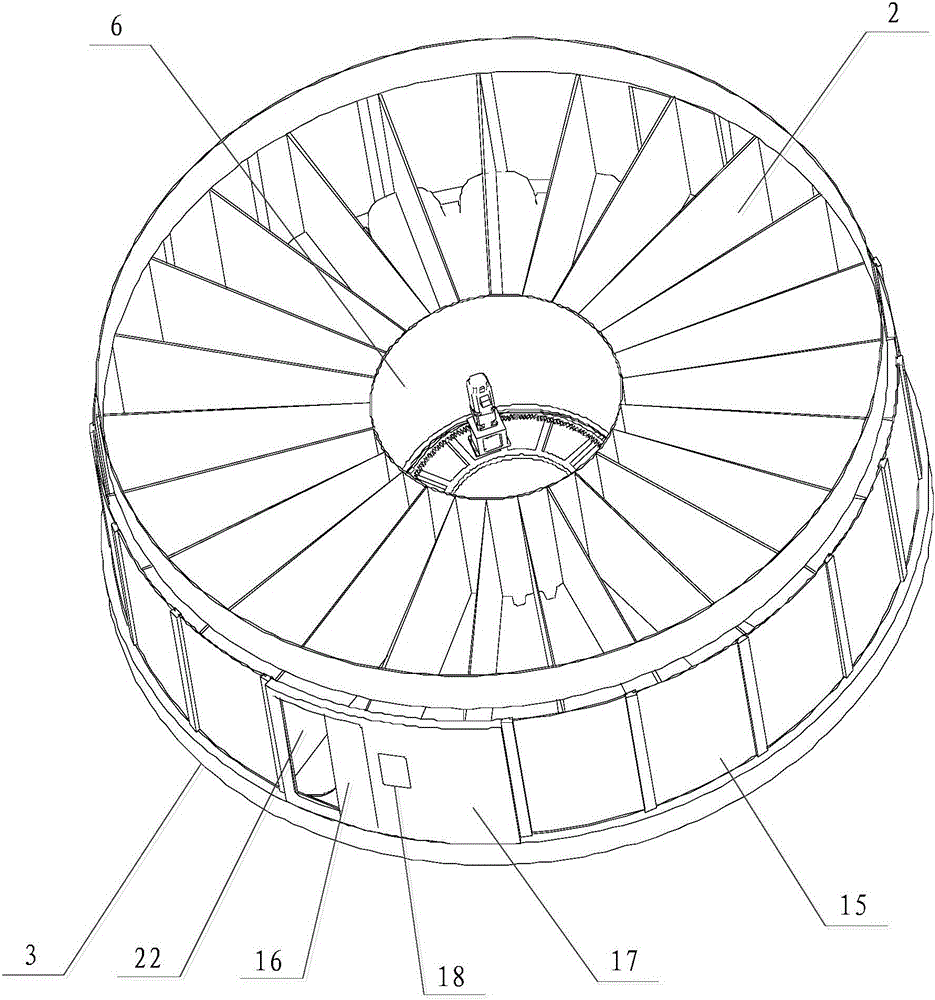

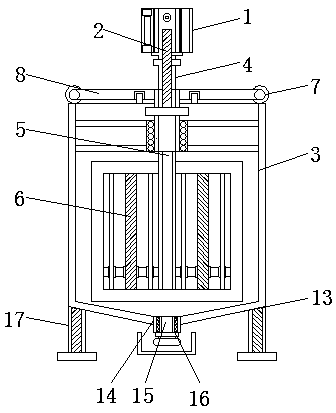

Coaxial double-blade submersible mixer for large fermentation tank

ActiveCN106367312AEnhance push flowImprove streaming effectBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMulti phase

The invention relates to a gas-liquid-solid multi-phase mixing device for a fermentation tank, in particular to a coaxial double-blade submersible mixer for a large fermentation tank. The coaxial double-blade submersible mixer comprises a submersible motor, an inner rotating shaft, an outer rotating shaft, a first bevel gear, a second bevel gear and two groups of blades of which the installation directions are opposite; the first bevel gear and the second bevel gear are arranged in the submersible motor and driven by a rotor arranged in the submersible motor to synchronously rotate, the outer rotating shaft is installed on the submersible motor, the end, located in the submersible motor, of the outer rotating shaft is fixedly connected with the second bevel gear, the end, located outside the submersible motor, of the outer rotating shaft is fixedly connected with the first groups of blades, the inner rotating shaft is arranged in the outer rotating shaft, one end of the inner rotating shaft stretches out of the outer rotating shaft and penetrates through the second bevel gear to be fixedly connected with the first bevel gear, and the other end of the inner rotating shaft stretches out of the outer rotating shaft to be fixedly connected with the second groups of blades. According to the coaxial double-blade submersible mixer, coaxial opposite-blade mixing can be achieved, and the mixing and stirring effects achieved in the large fermentation tank are greatly improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

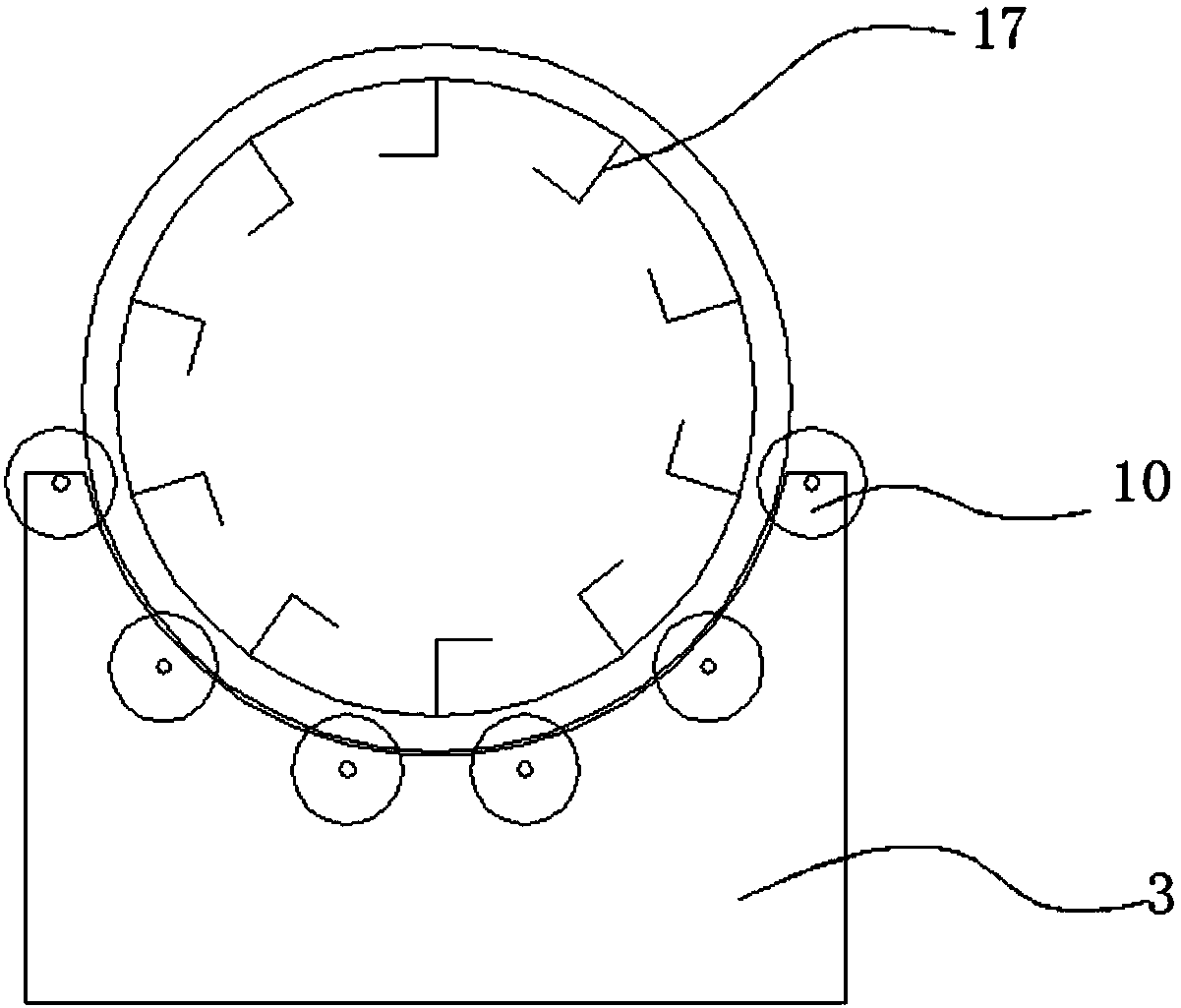

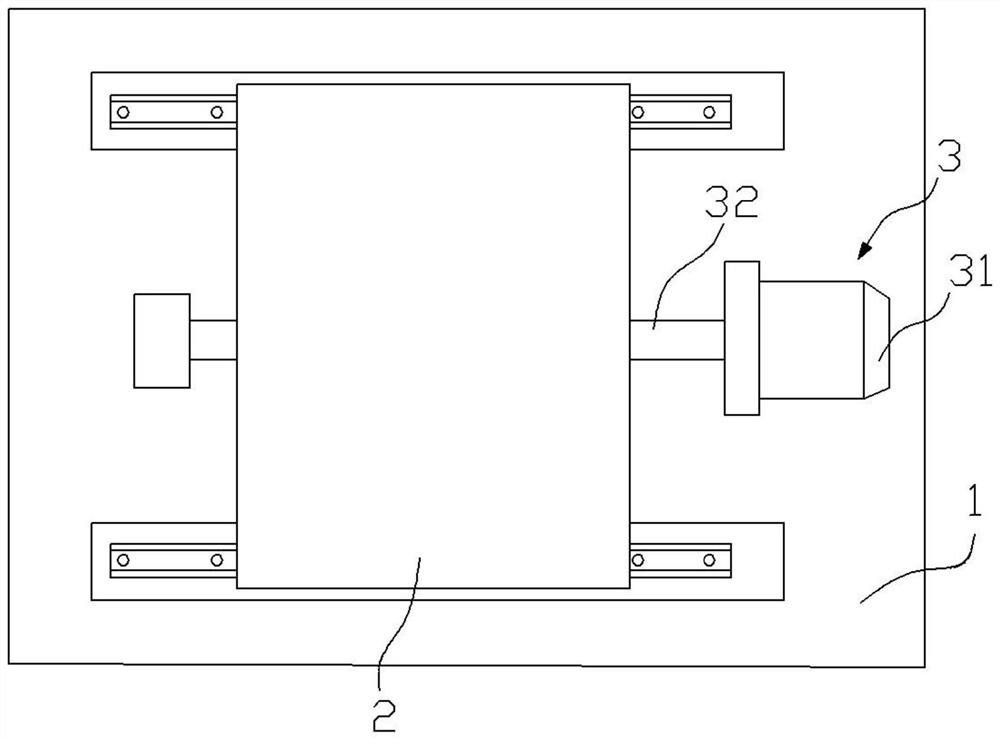

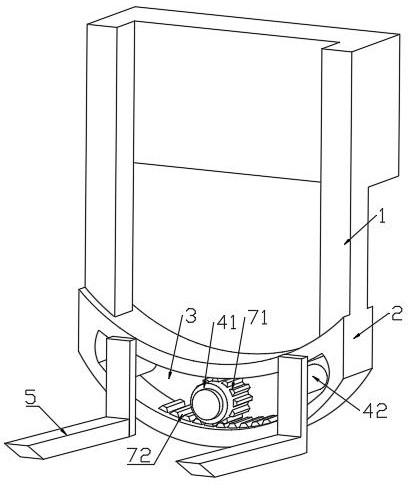

Oil drum rotating printing device

InactiveCN111619206AUniform rotation speedDoes not affect print qualityScreen printersScreen printingPhysicsEngineering

The invention relates to a printing device, in particular to an oil drum rotating printing device. The invention aims to provide the oil drum rotating printing device which enables the rotating speedof an oil drum to be more uniform and does not influence the printing quality. The oil drum rotating printing device comprises a bottom plate and supports, wherein a rack and an inclined plate are bolted on the upper side of the bottom plate, and rollers for reducing friction force are rotatably mounted on two sides of the top of the bottom plate; and at least two supports are provided and arranged on two sides of the top of the bottom plate, an idler wheel is located between the supports at the both sides, and the rollers and the supports are all located between the rack and the inclined plate. According to the oil drum rotating printing device, the oil drum is driven to rotate through a printing assembly, the oil drum can be printed, and the oil drum can be rotated mechanically instead of manually, so that the rotating speed of the oil drum is more uniform, and the printing quality is not influenced.

Owner:夏伟

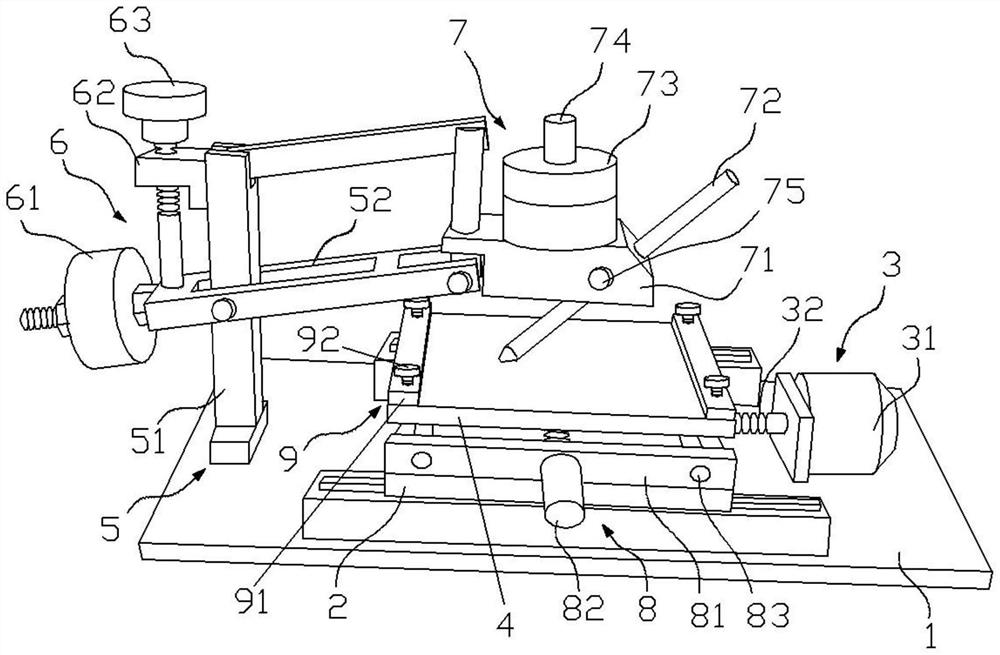

Spraying method of wear-resistant coating of coating scraper and spraying mounting and clamping tool thereof

InactiveCN101886240AIncrease stiffnessImprove impact resistanceMolten spray coatingThermal sprayingWear resistant

The invention discloses a spraying method of a wear-resistant coating of a coating scraper and a mounting and clamping tool thereof, and the mounting and clamping tool consists of a workbench which is driven by a speed adjusting motor and rotates horizontally and a metal outer hoop and a tension inner hoop mounted on the workbench, wherein the tension inner hoop is provided with an opening, a puller bolt and a tension stop block are arranged at the opening, a ring of step is arranged on the inner wall of the metal outer hoop, and the height of the step is equivalent to the width of the coating scraper. When in spraying, the coating scraper is firstly mounted on the mounting and clamping tool, then a sand blasting gun is used for firstly carrying out sand blasting treatment on the coating scraper, and a plasma spraying gun is finally used for spraying the wear-resistant layer. The spraying method and the mounting and clamping tool can solve the technical problem of deformation of the coating scraper due to heating during the thermal spraying process.

Owner:SHANDONG UNIV OF SCI & TECH

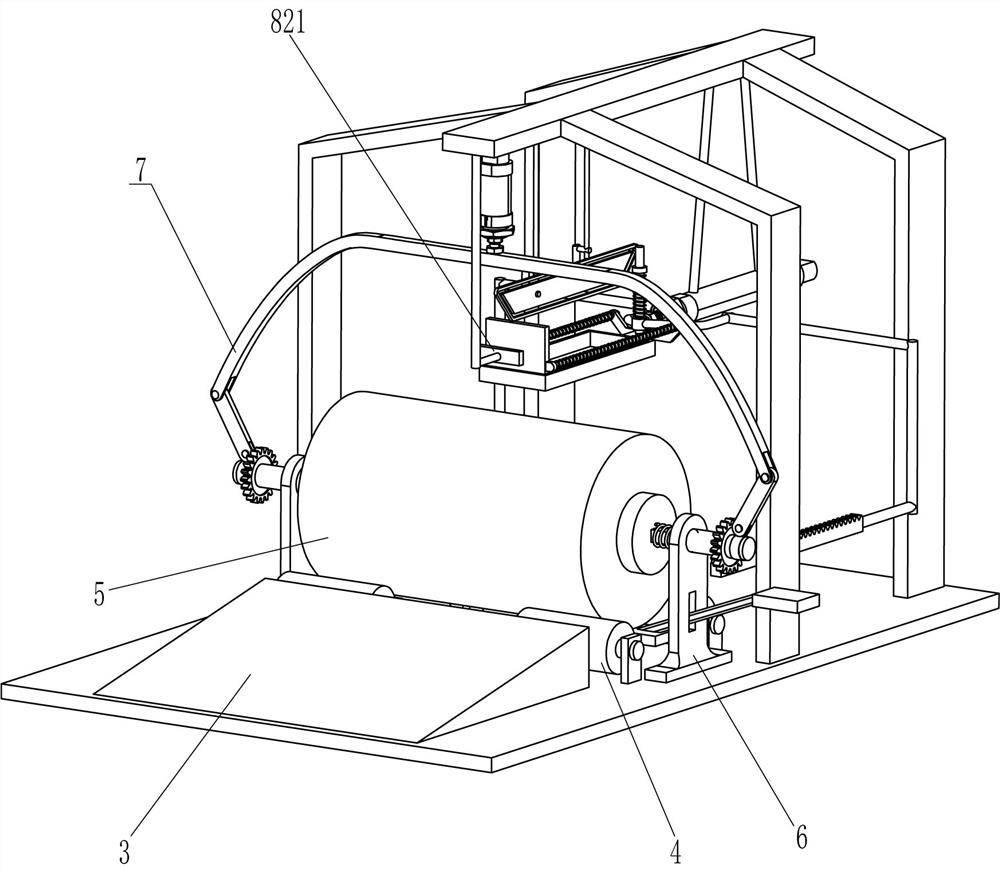

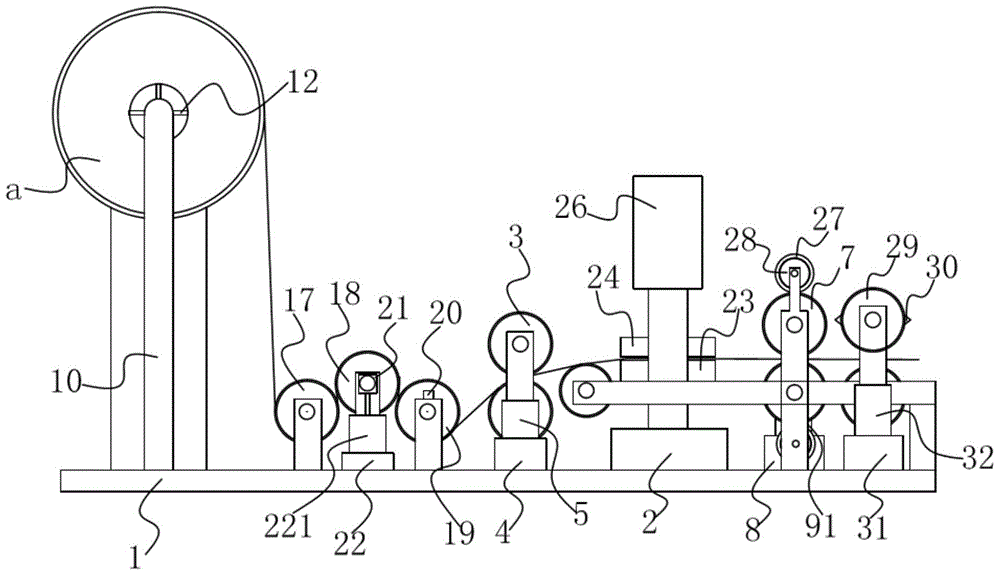

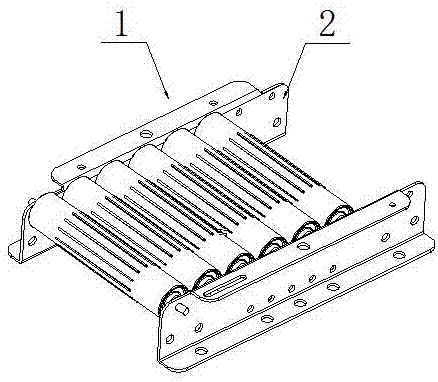

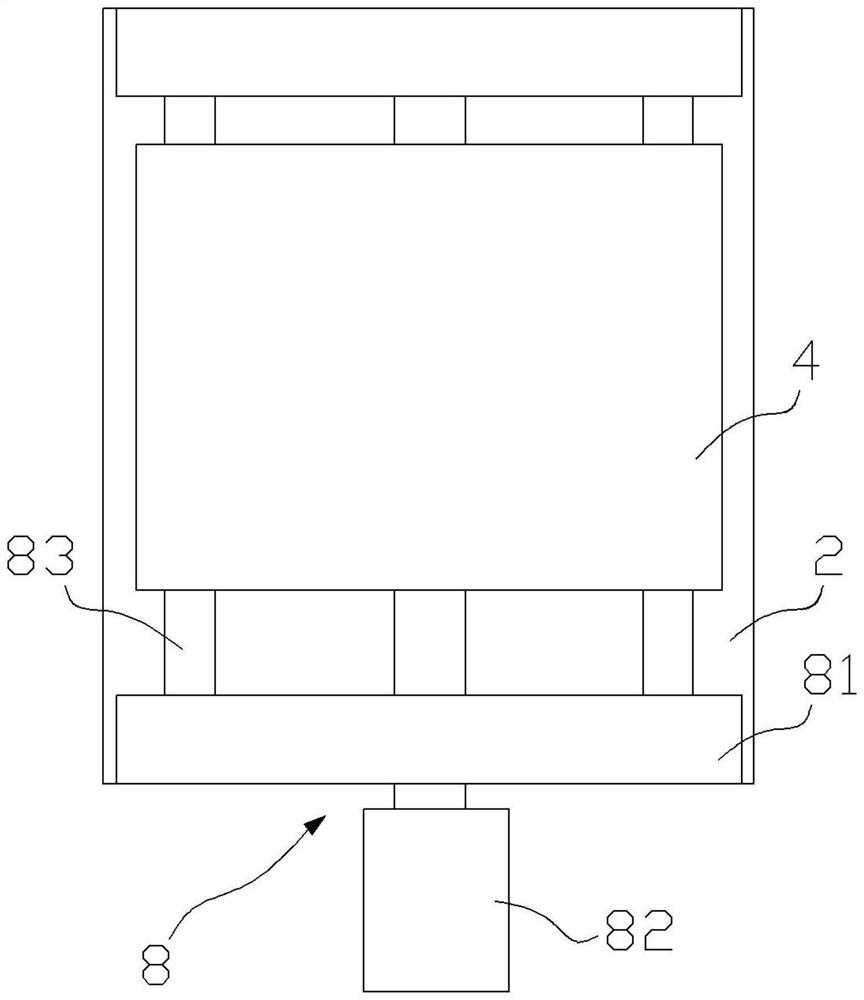

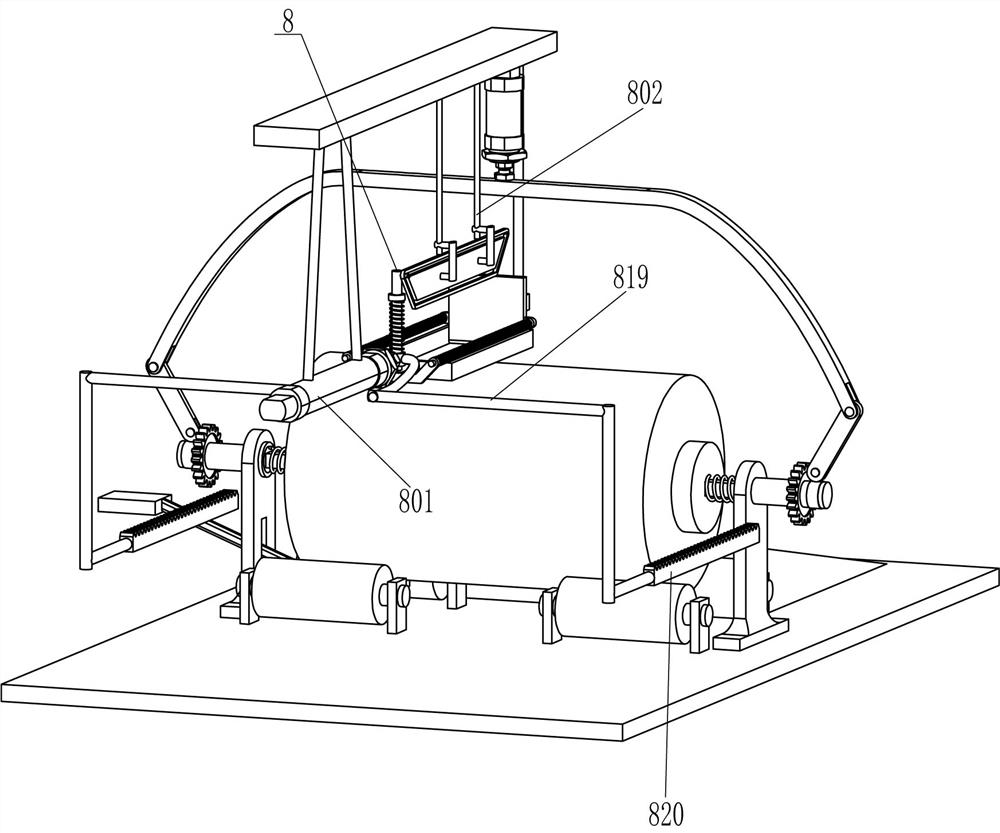

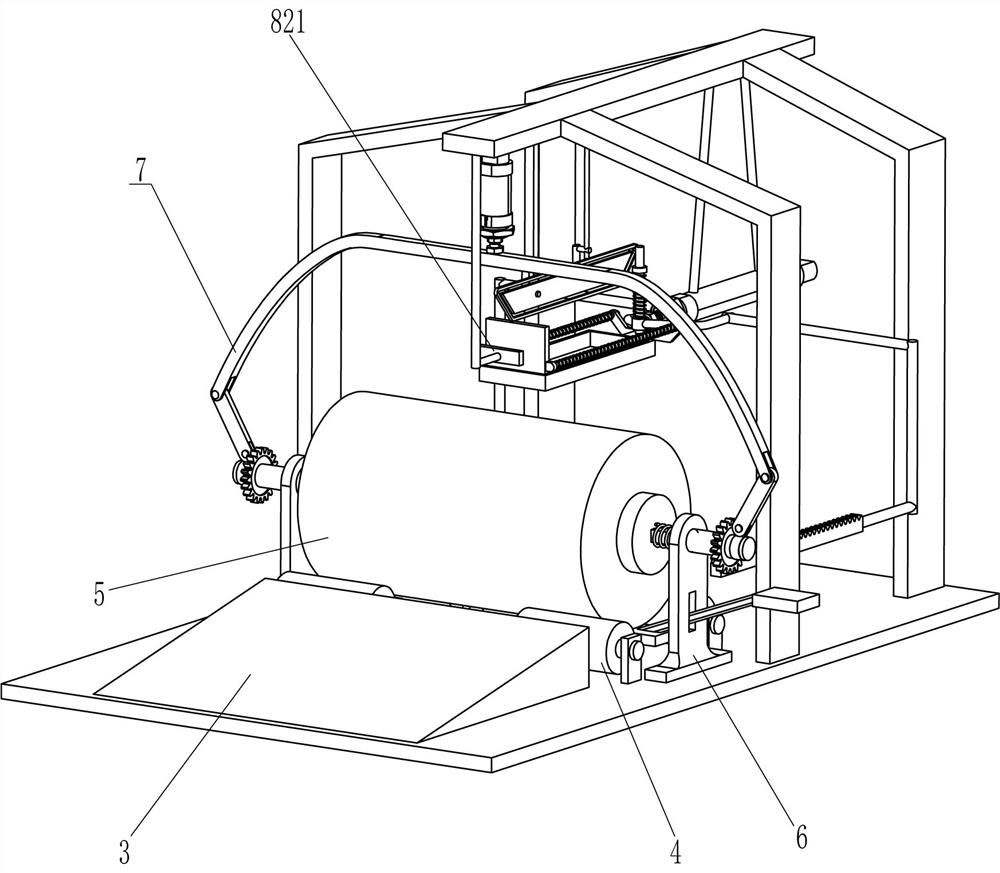

Heat dissipation belt forming system

ActiveCN104858662ASimple structureUniform rotation speedOther manufacturing equipments/toolsFrequency conversionMechanical engineering

The invention discloses a heat dissipation belt forming system. The system comprises an unrolling mechanism, a feeding mechanism, a straightening and flattening mechanism, a rolling mechanism and a programmable controller. The unrolling mechanism is arranged on a rack and used for fixing a heat dissipation belt piece roll. The feeding mechanism, the straightening and flattening mechanism, the rolling mechanism and the programmable controller are sequentially located on one side of the unrolling mechanism. A tension detection assembly is arranged on a tensioning roll, an adjusting channel is formed in the straightening and flattening mechanism, is parallel with the moving direction of the heat dissipation belt piece, and is used for passing of the heat dissipation belt piece so that the heat dissipation belt piece can be straightened and flattened, and the rolling mechanism is composed of a pair of rolling die rolls capable of rotating oppositely and an oil coating assembly, the surfaces of the rolling die rolls are coated with lubricating oil through the oil coating assembly, and a first frequency converter and a second frequency converter are connected with the programmable controller. Compared with the prior art, the structure is simplified, speeds and tension of all the mechanisms are controlled accurately to be constant through frequency conversion by the programmable controller so that conveying rolls and the rolling die rolls can be uniform in rotation speed; the lubricating oil is provided for the rolling die rolls through the oil coating assembly, in this way, abrasion to the rolling die rolls after long-time using is prevented, product quality is improved, and smooth production is guaranteed.

Owner:ZHEJIANG CHUANGXIN AUTO AIR CONDITIONER

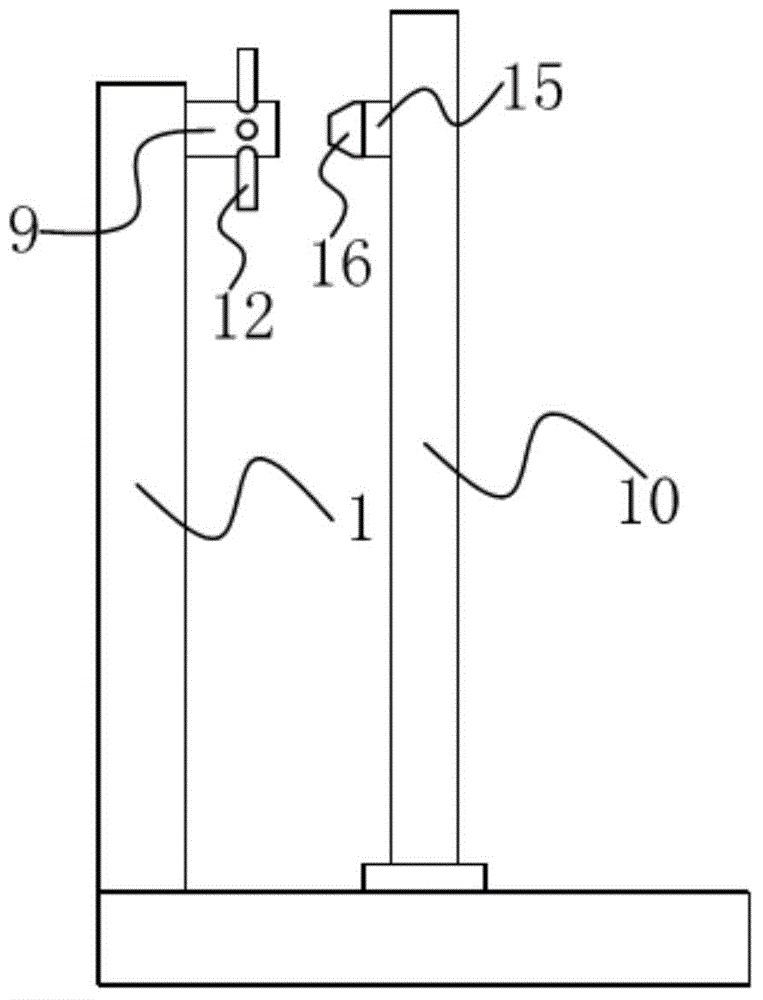

Mechanism for coating oil on enameled wire by using liquid paraffin

InactiveCN102364610AImprove oiling effectUniform rotation speedCable/conductor manufactureOil canElectric machine

The invention discloses a mechanism for coating oil on an enameled wire by using liquid paraffin. The mechanism is arranged on a main body of a processing mechanism and comprises a motor, an oil groove, a felt and a rotary roller, wherein the rotary roller is arranged on the oil groove; the motor is arranged on one side of the oil groove and connected with the rotary roller to control the rotary roller to rotate; a roller groove which corresponds to the enameled wire to be subjected to oil coating is formed on the rotary roller; the roller groove makes a circle on the rotary roller; the enameled wire to be subjected to oil coating passes through the roller groove of the rotary roller; liquid lubricating oil is arranged in the oil groove; the rotary roller is immersed in the liquid lubricating oil; a protruded bracket is arranged in the front of the oil groove; the felt is placed on the protruded bracket of the oil groove; the felt comprises a lower felt and an upper felt; and the enameled wire to be subjected to oil coating passes between the lower felt and the upper felt. By designing the mechanism for coating the oil on the enameled wire by using the liquid paraffin, the enameled wire can be subjected to oil coating by using the liquid paraffin, so that the oil can be more uniformly coated on the enameled wire.

Owner:SUZHOU XINDI ELECTRICAL

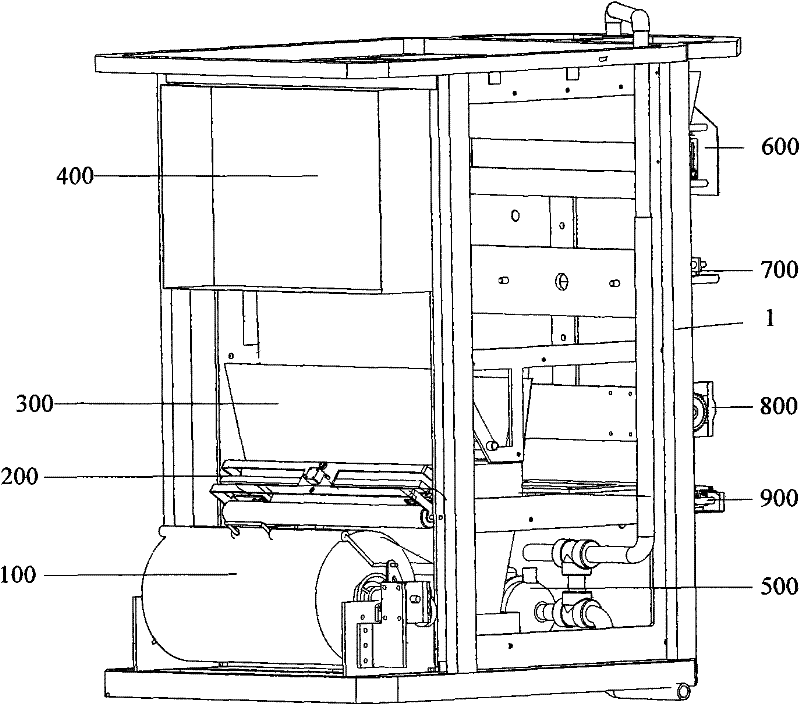

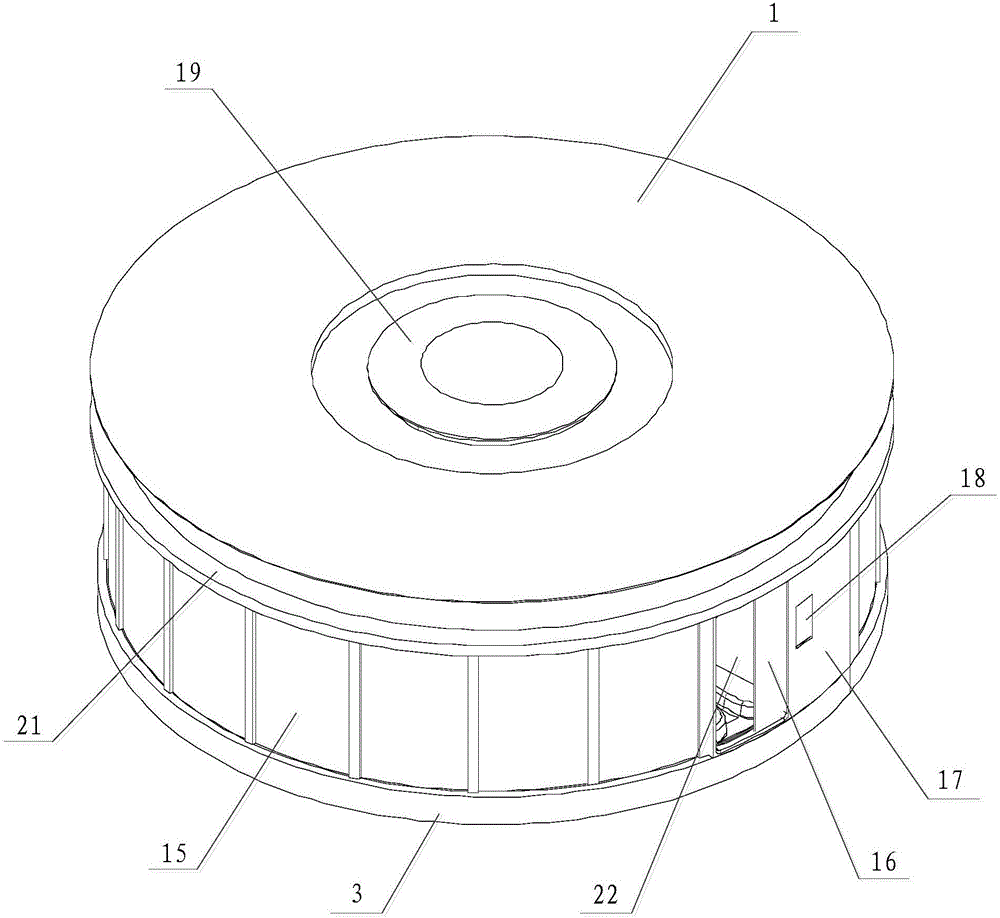

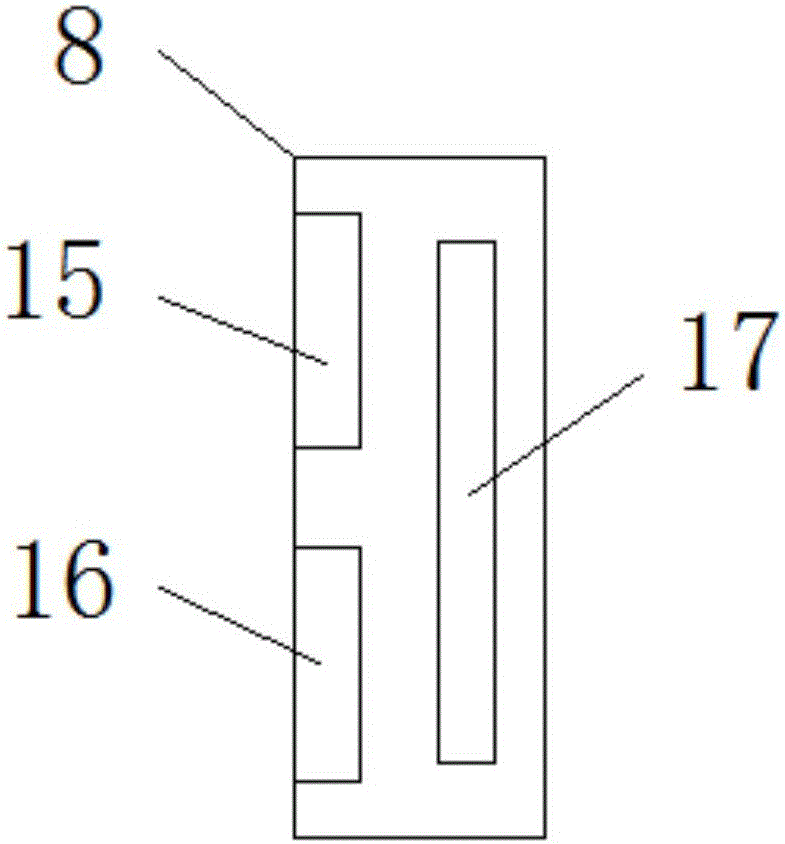

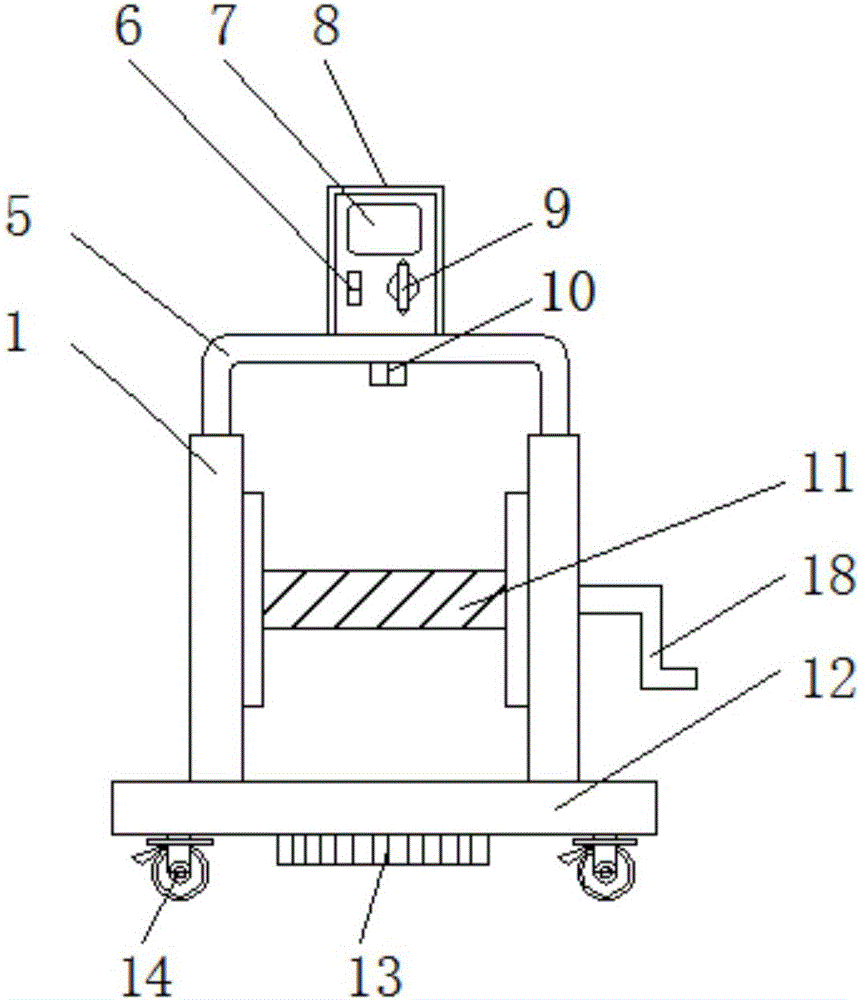

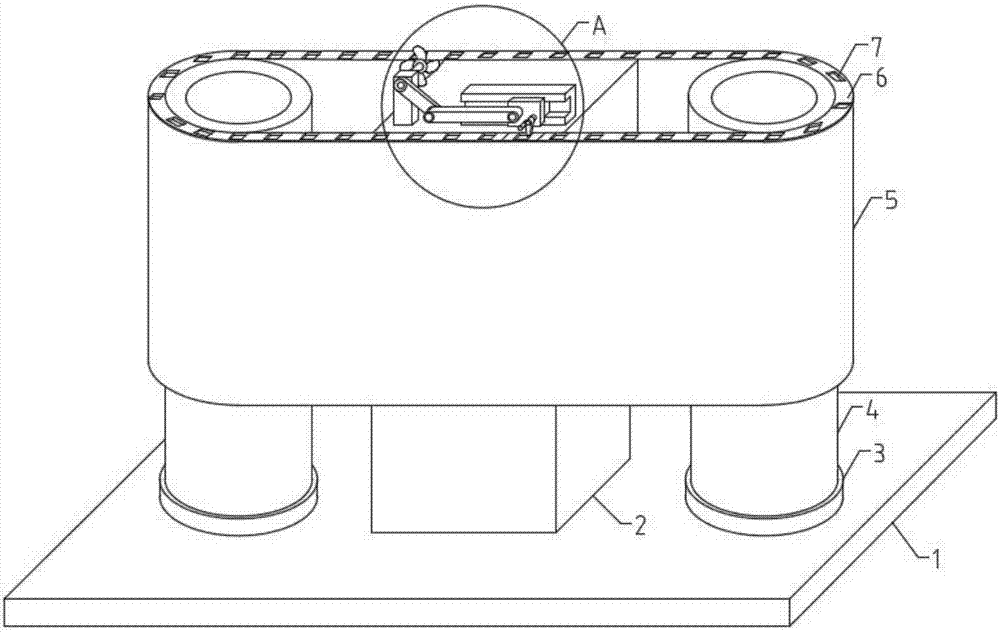

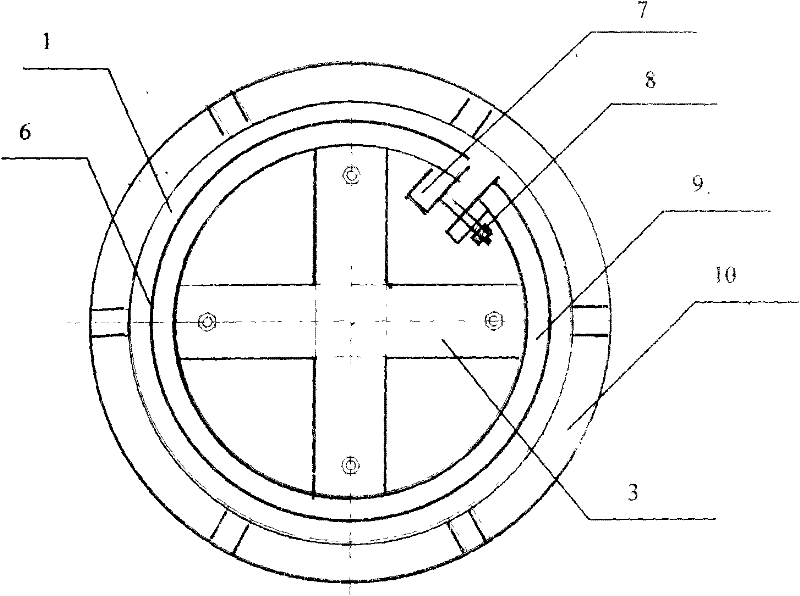

Bicycle depositing management device

The invention relates to a bicycle depositing management device. The bicycle depositing management device comprises a depositing device main body, an intelligent control device, and a rotation control device; the depositing device main body comprises at least one layer of a depositing database; the depositing compartments of different layers are stacked successively up and down; the depositing compartment of each layer consists of a plurality of rotatable depositing units; a rotary control device is arranged inside the depositing device main body for driving the depositing units to rotate; and an intelligent control device is arranged on the outer side wall of the depositing device main body and is in signal connection with the rotary control device. The technical scheme of the bicycle depositing management device provides a management device which can intelligently store bicycles and can realize intelligent bicycle storage and picking-up through intelligently controlling a rotary platform, which is simple, convenient and efficient.

Owner:许志雄

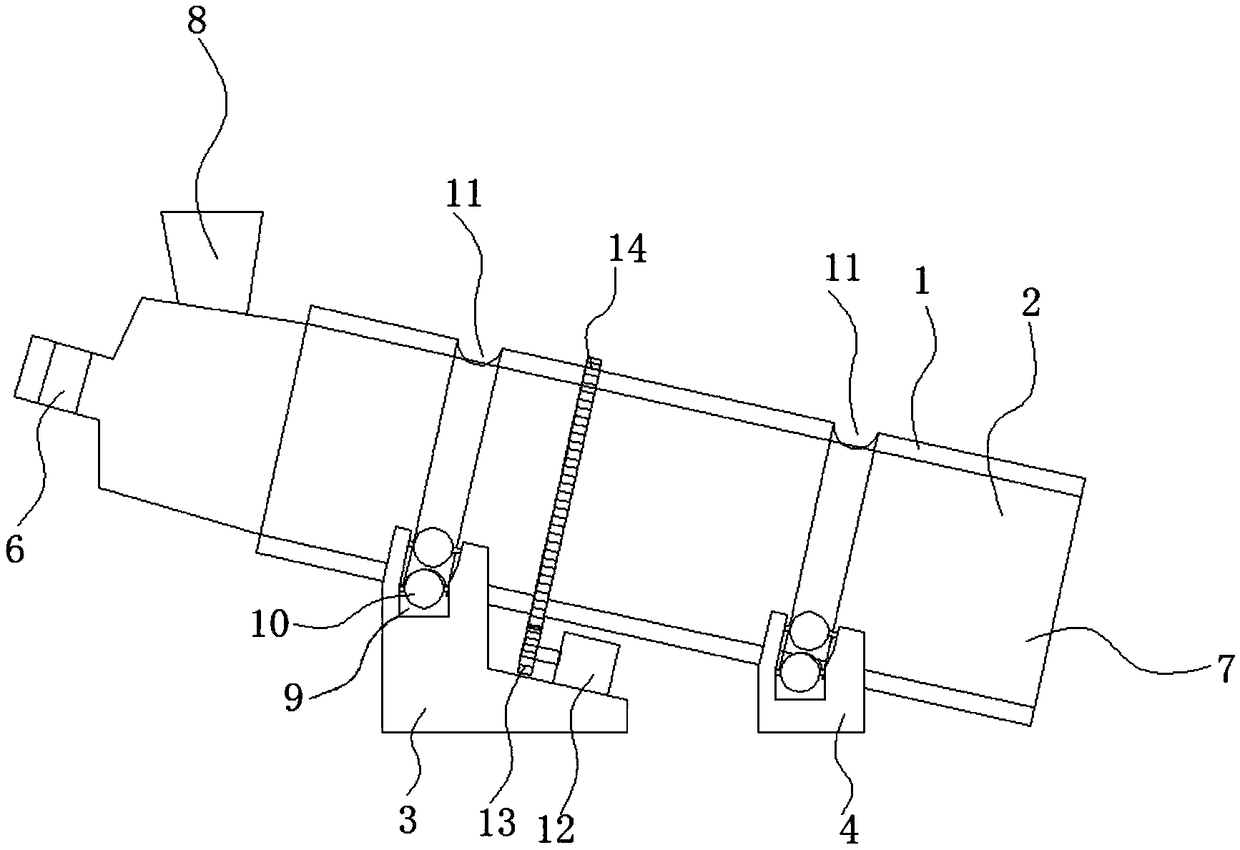

Rotary drum drier

InactiveCN108317826AImprove drying efficiencyImprove balanceDrying gas arrangementsDrying machines with non-progressive movementsBalance performanceFriction force

The invention discloses a rotary drum drier which comprises an outer drum, an inner drum, a first base, a second base and a driving device. The inner drum and the outer drum are arranged on the firstbase and the second base in an inclined manner, a heater is arranged between the outer drum and the inner drum, an air blower is arranged at the front end of the inner drum, a discharging opening is formed in the back end, and a putting opening is formed in the front portion of the inner drum; and installing grooves and balls are arranged on the first base and the second base, the balls are hingedinto the installing grooves, and an arc-shaped groove rail allowing the balls to roll therein is formed in the outer drum. According to the rotary drum drier, the arc-shaped groove rail is arranged on the exterior of the outer drum, the multiple balls with the good wear-resisting property are arranged on the first base and the second base, when the drier rotates, the balls roll in the arc-shapedgroove rail, the friction force generated during drum rolling is reduced, the drum rotating speed is more even, and the drying efficiency is higher; and the two rings of balls are arranged, the overall drier balance performance is more excellent, gear abrasion is reduced, and the maintenance period of the driving device is prolonged.

Owner:扬州益洋科技发展有限公司

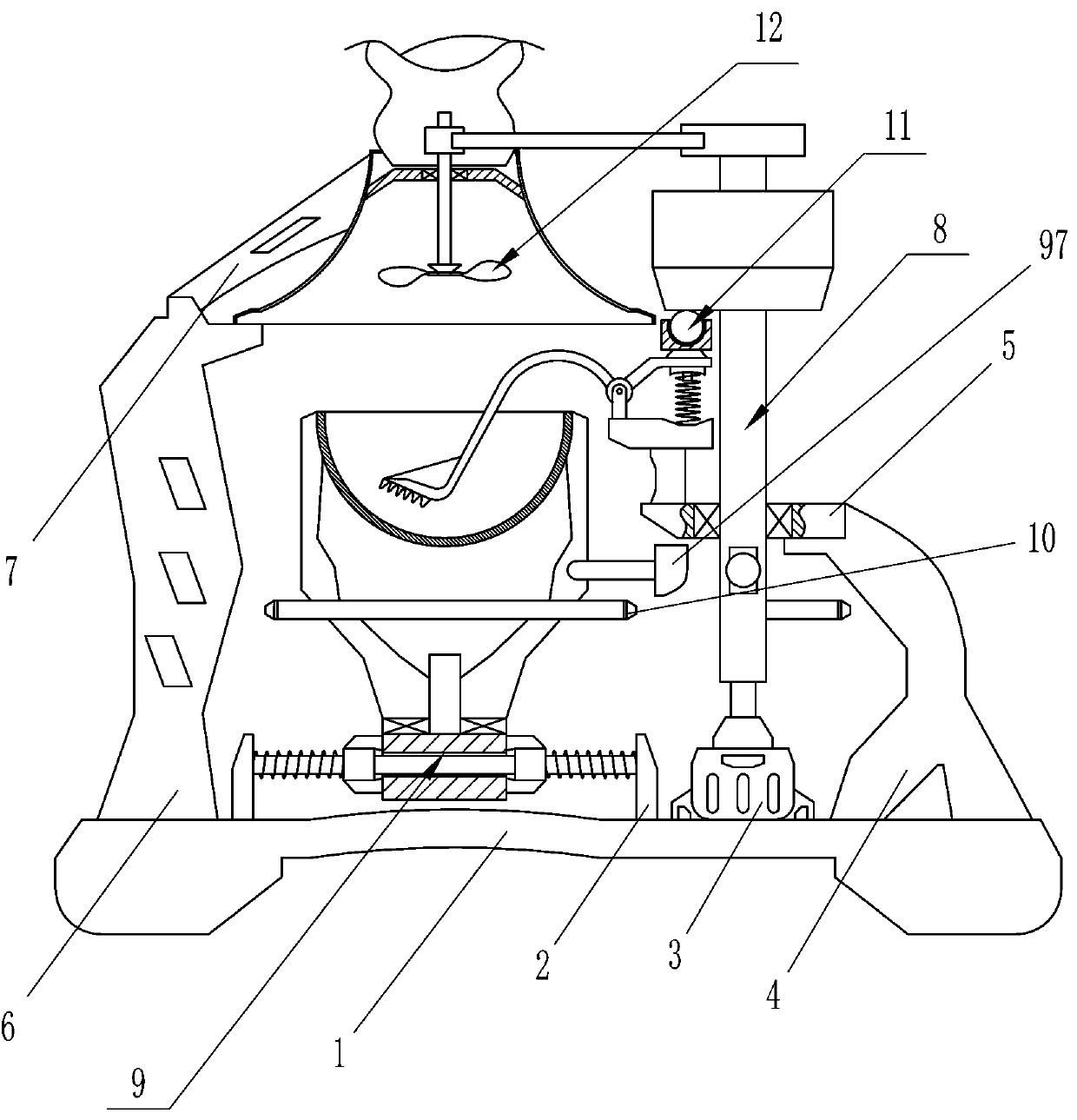

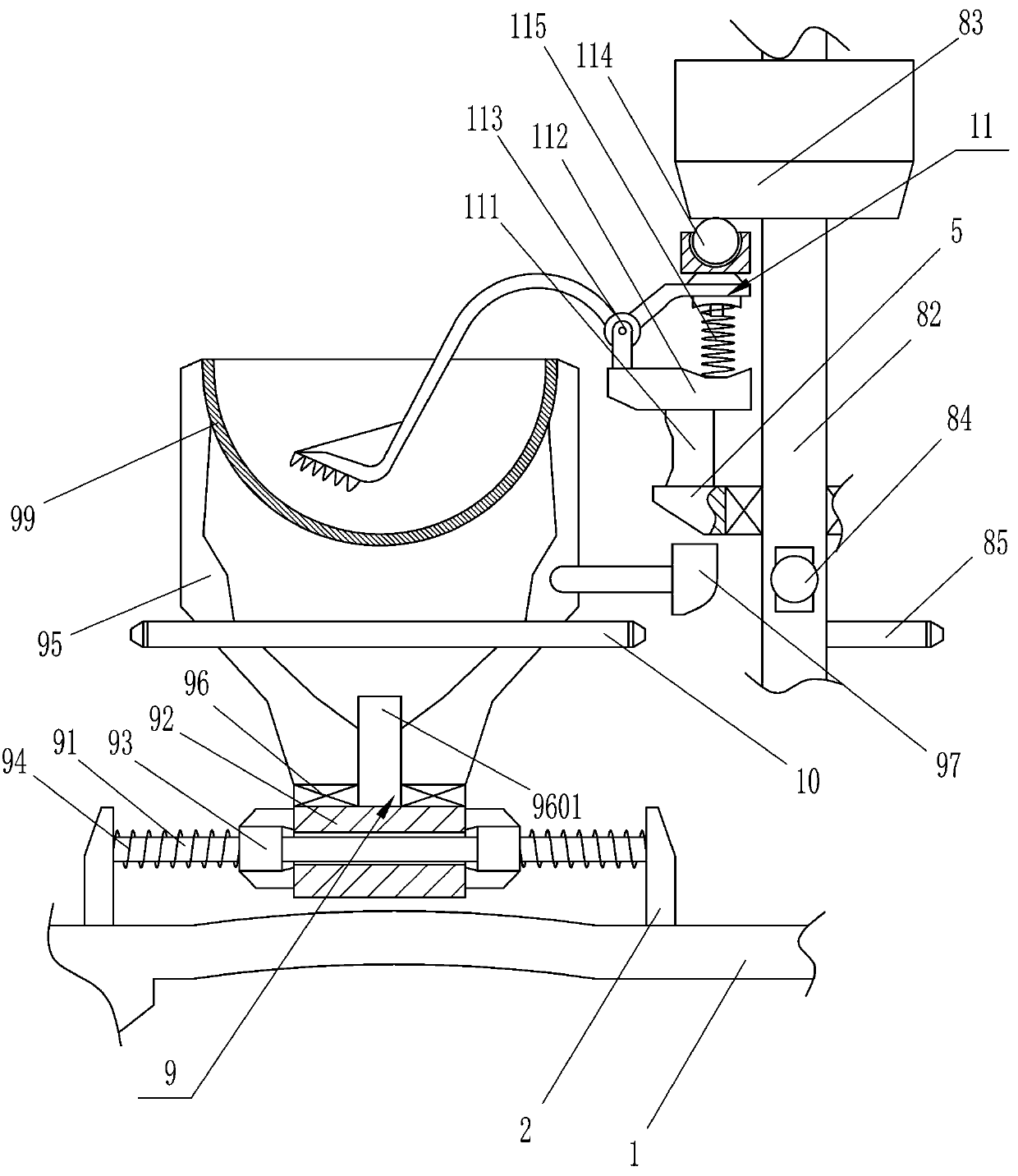

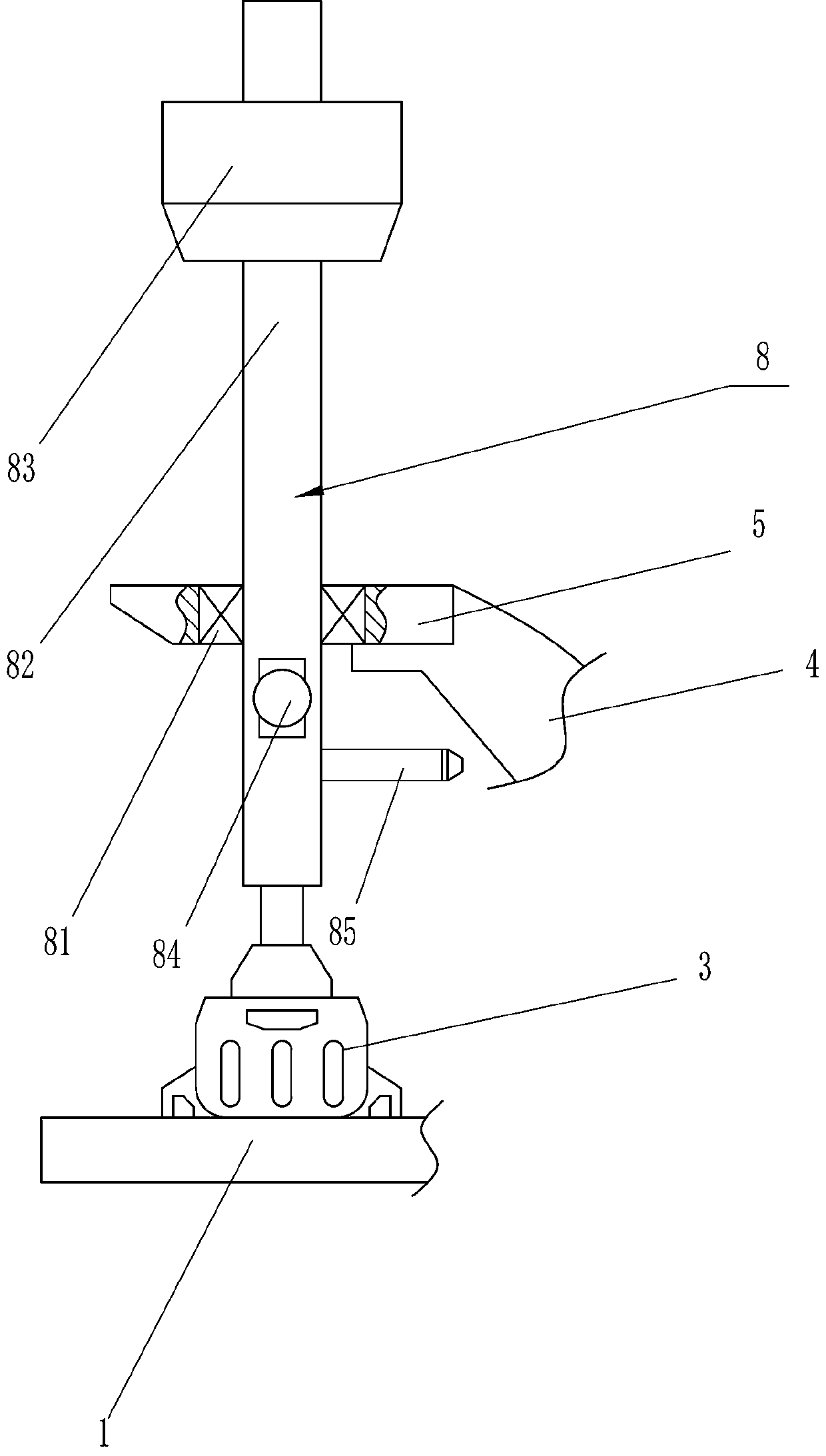

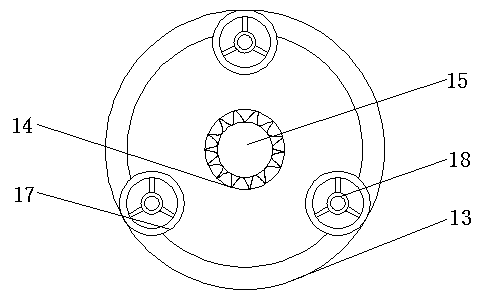

Automatic stir-frying equipment for kaffir lily fertilizer cannabis sativa seeds

The invention relates to fertilizer processing, in particular to automatic stir-frying equipment for kaffir lily fertilizer cannabis sativa seeds. According to the automatic stir-frying equipment forthe kaffir lily fertilizer cannabis sativa seeds, manual direct participation is not needed in stir-frying processing of the cannabis sativa seeds, the automation degree is high, and the cannabis sativa seeds are heated evenly. The automatic stir-frying equipment for kaffir lily fertilizer cannabis sativa seeds comprises a bottom plate, first supports, a motor and a second support; two sets of first supports are connected to the bottom plate, the motor is connected to the right side of the bottom plate, the second support is connected to the right side of the bottom plate, and the second support is located on the right side of the motor. A first cam, a first connecting rod and a single gear on a power device are used for stir-frying, shaking and rotating the cannabis sativa seeds respectively, so that the stir-frying spatula is automatic, and the cannabis sativa seeds are uniformly heated due to uniform stir-frying force and uniform rotating speed in the stir-frying process.

Owner:吴彦坤

Conveniently cleaned honey extractor for beekeeping

PendingCN109197681AReduce labor intensityEasy to take outHoney collectionDrive shaftElectric machinery

The invention discloses a conveniently cleaned honey extractor for beekeeping, which comprises a motor, cover plates and an inclined panel, and is characterized in that the outer side of the motor iswelded with a motor frame, a transmission shaft is installed below the motor, the lower end of the transmission shaft is connected with a main rod, the outer side of the main rod is fixedly provided with a stainless steel frame, the left and right sides of the upper surface of a sealed barrel are provided with rotating shafts respectively, the outer surface of each cover plate is provided with anarc slot, the lower surface of each cover plate is provided with a limit slot, the upper surface of the sealed barrel is covered with a dust screen, and the lower end of the inclined panel is fixed with a discharge pipe. The conveniently cleaned honey extractor for beekeeping provides a centrifugal force through the motor, thereby reducing the labor intensity of workers. In addition, the strengthand speed of the centrifugal force can be accurately controlled, thereby being conducive to extracting honey from the honey comb; and secondly, the honey extractor is not directly contacted with the outside air after being cleaned, thereby avoiding dust adsorbing inside the honey extractor.

Owner:贵州省台江县苗誉蜂业有限公司

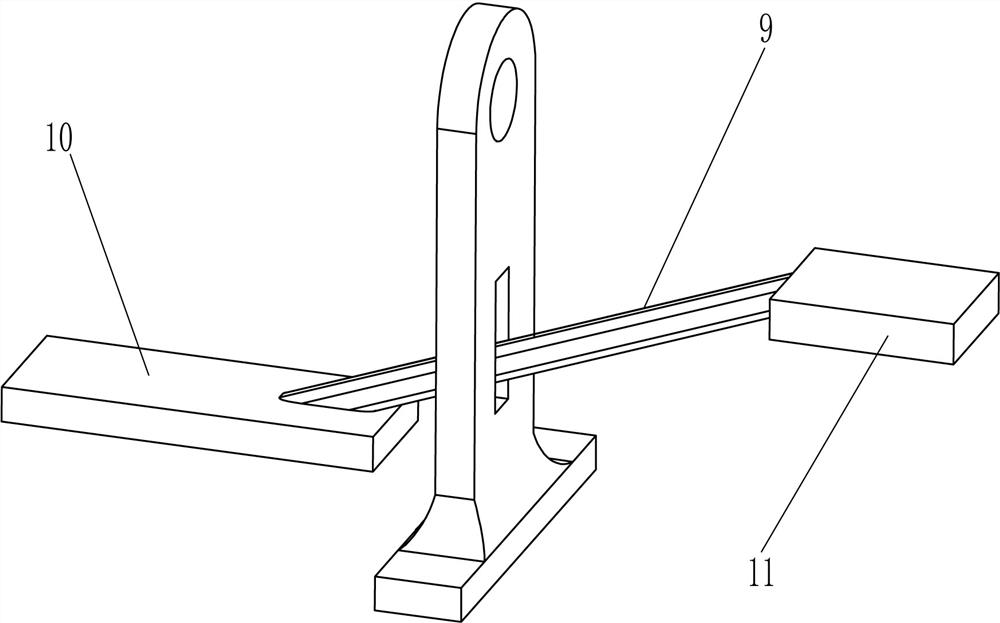

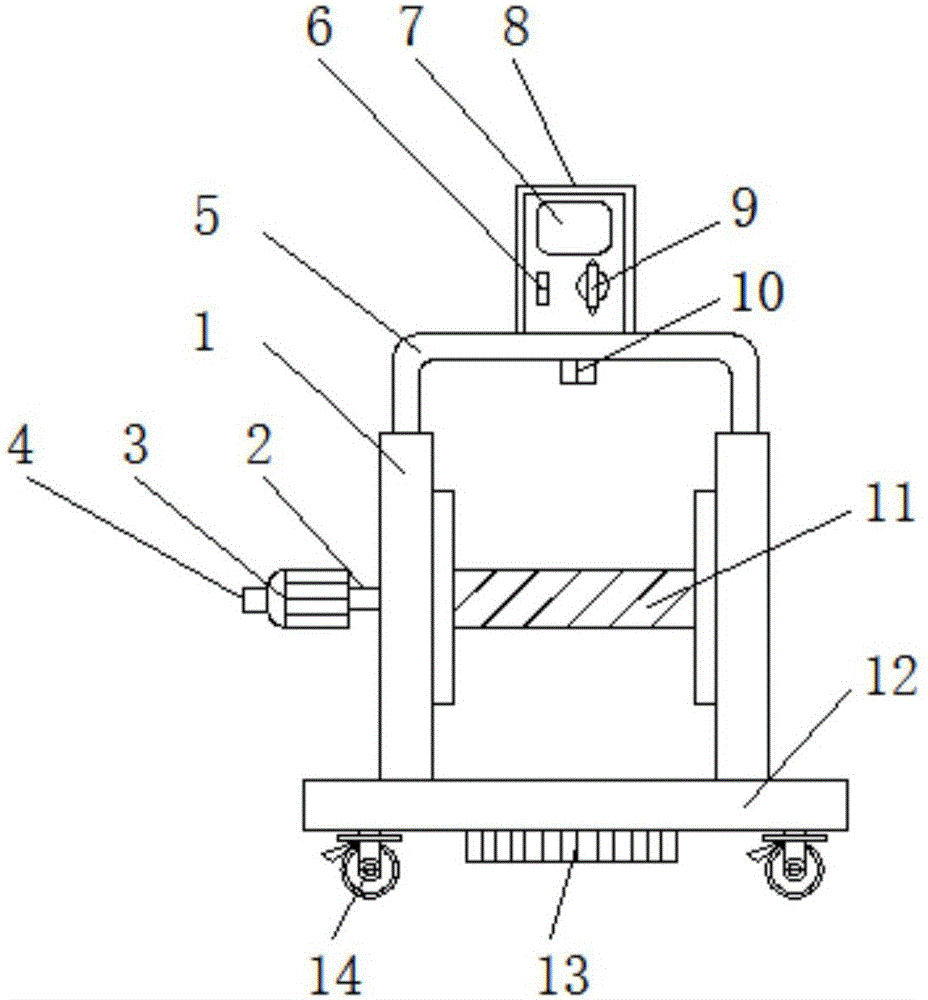

Multifunctional cable guider

InactiveCN106144785AEasy to moveRealize the collectionFilament handlingDigital analog converterLiquid-crystal display

The invention discloses a multifunctional cable guide, which comprises a speed regulator and a support base. The support base is equipped with a guide support column, and a cable collection roller is installed between the guide support columns. The driving motor A motor controller is installed on the front surface of the control box, and an LED liquid crystal display and a start button are installed on the front wall of the control box. The start button is located under the LED liquid crystal display, and the digital-to-analog converter is located above the ARM processor. The circuit board is located on the right side of the ARM processor, and a universal self-locking wheel and a shock absorber are installed on the bottom of the support base, and the shock absorber is located between the universal self-locking wheels. In the present invention, the rotational speed of the drive motor can be controlled by the speed controller, so that the drive motor moves at a constant speed, and the timer starts counting at the same time, and the specific length of the cable wrapped by the cable collection drum can be calculated from the time and the running speed, which is convenient for the staff. Observe and record.

Owner:陈震英

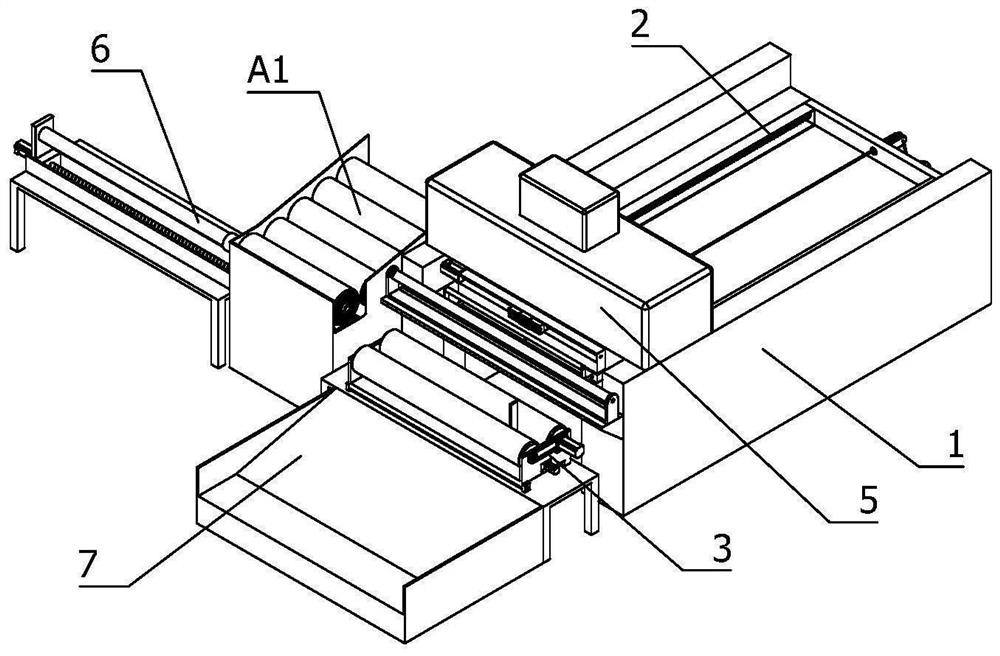

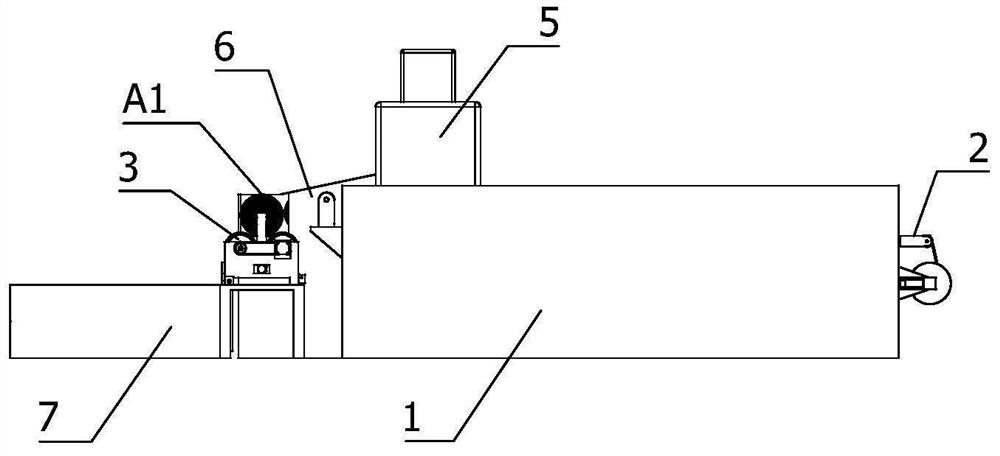

Cloth inspecting and rolling machine for silk cloth

ActiveCN113718509AAccurate pre-detectionAvoid detection blind spotsInspecting textilesConveyor partsSilk clothMechanical engineering

The invention relates to the technical field of cloth inspecting and rolling machines, in particular to a cloth inspecting and rolling machine for silk cloth. The cloth inspecting and rolling machine for the silk cloth comprises a rack, a tiling conveying device, a cloth inspecting machine, a feeding device and a discharging rail, wherein the tiling conveying device is fixedly mounted on the rack; the cloth inspecting machine is arranged above the tiling conveying device and is fixedly connected with the rack; the feeding device is arranged on the side of the tiling conveying device; the discharging rail is arranged on the side of the tiling conveying device; the tiling conveying device further comprises a horizontal traction device, a cloth rolling device and an overturning driving device; the horizontal traction device is fixedly mounted on the rack; the cloth rolling device is rotationally mounted on the rack; and one end of the overturning driving device is fixedly connected with the rack, and the end, away from the rack, of the overturning driving device is rotationally connected with the cloth rolling device. The cloth can be accurately pre-inspected, a non-inspection zone is avoided, and the product quality is effectively guaranteed.

Owner:深圳同益新中控实业有限公司

Industrial wheel detection device

The invention discloses an industrial wheel detection device. The industrial wheel detection device comprises a bottom plate, wherein two T-shaped sliding grooves are formed in the top surface of thebottom plate; T-shaped sliding blocks are slidingly arranged in the two T-shaped sliding grooves respectively; the top surfaces of the T-shaped sliding blocks penetrate out of the T-shaped sliding grooves and are fixedly connected with connecting rods; a circular plate is embedded in one side of the top surface of the bottom plate at the side ends of the two T-shaped sliding grooves and is rotationally connected with the bottom plate; a handle is fixedly connected to the side end of the circular plate, and the bottom surface of the circular plate is fixedly connected with a T-shaped rotating block; and the T-shaped rotating block is embedded into the bottom plate and is rotationally connected with the bottom plate. Through the arrangement of a motor and a speed reducer, the defect of manually rotating the wheel is effectively overcome, so that the uniform rotation speed of the circumference of the wheel is effectively guaranteed, and the accuracy of the detection data is effectively improved. The detection device is simple in structure, convenient to operate and low in cost, and the practical performance of the wheel detection device is effectively improved.

Owner:开平市骏达五金制品有限公司

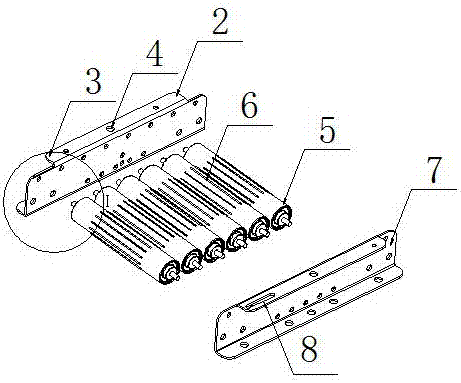

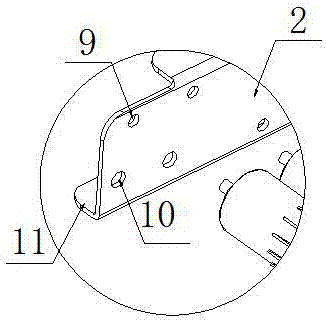

Rotary conveying device for processing bagged ham sausage

InactiveCN107323941ASmooth and reliable rotationThe rotary conveying is stable and reliableConveyorsRoller-waysEngineeringFrictional resistance

The invention discloses a rotary conveying device for processing bagged ham sausage. The device comprises a first clamping frame. An upper clamping plate is horizontally arranged above the first clamping frame, an upper fixing hole is formed in the middle of the upper clamping plate, and a rotary conveying set is installed on one side of the first clamping frame; and a plurality of rotary receiving rollers are installed on the rotary conveying set, second clamping frames are perpendicularly arranged on one sides of the rotary receiving rollers correspondingly, clamping grooves are horizontally formed above the second clamping frames correspondingly, and a lower clamping plate is horizontally arranged below the first clamping frame. When rotary conveying is conducted on the bagged ham sausage by the rotary receiving rollers, protruding strips between every two adjacent rotary receiving rollers are mutually supported in a clamped mode and rotate in a swinging mode, and the rotary receiving rollers are driven by the multiple protruding strips to conduct mutual transmission; and the rotary receiving rollers are matched with the multiple protruding strips to improve the frictional resistance of the bagged ham sausage while it is ensured that the rotating speed of the rotary receiving rollers is smoother and evener, so that rotary conveying of the ham sausage is more efficient and thorough, the device is convenient to operate, and connection of the components is flexible.

Owner:蔡敬东

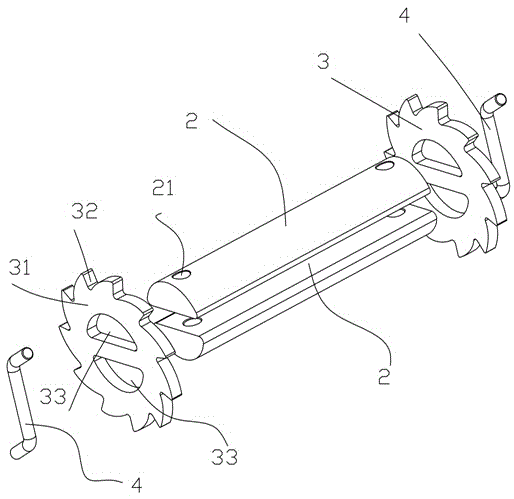

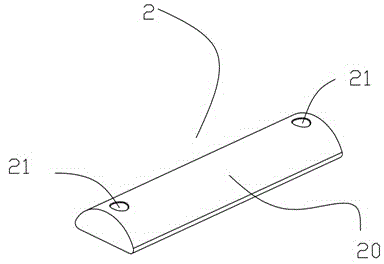

Traction device of wire drawing machine

The invention discloses a traction device of a wire drawing machine. The traction device of the wire drawing machine comprises a pair of connecting cross bars arranged in parallel, wherein detachable driving ratchet wheels are respectively arranged at the two ends of the connecting cross bars. The traction device of the wire drawing machine has the following advantages: when the wire drawing is performed, users can select the connecting cross bars with proper lengths according to the winding size, and install the driving ratchet wheels at the two sides of the connecting cross bars. As double driving ratchet wheels are adopted, the rotating speed of the connecting cross bars is uniform, the winding torque is high, and the winding efficiency of the wire drawing machine is greatly improved; and the traction device of the wire drawing machine is simple in structure, excellent in flexibility and strong in practicability.

Owner:NANTONG HUWANG PLASTIC SCI & TECH DEV CO LTD

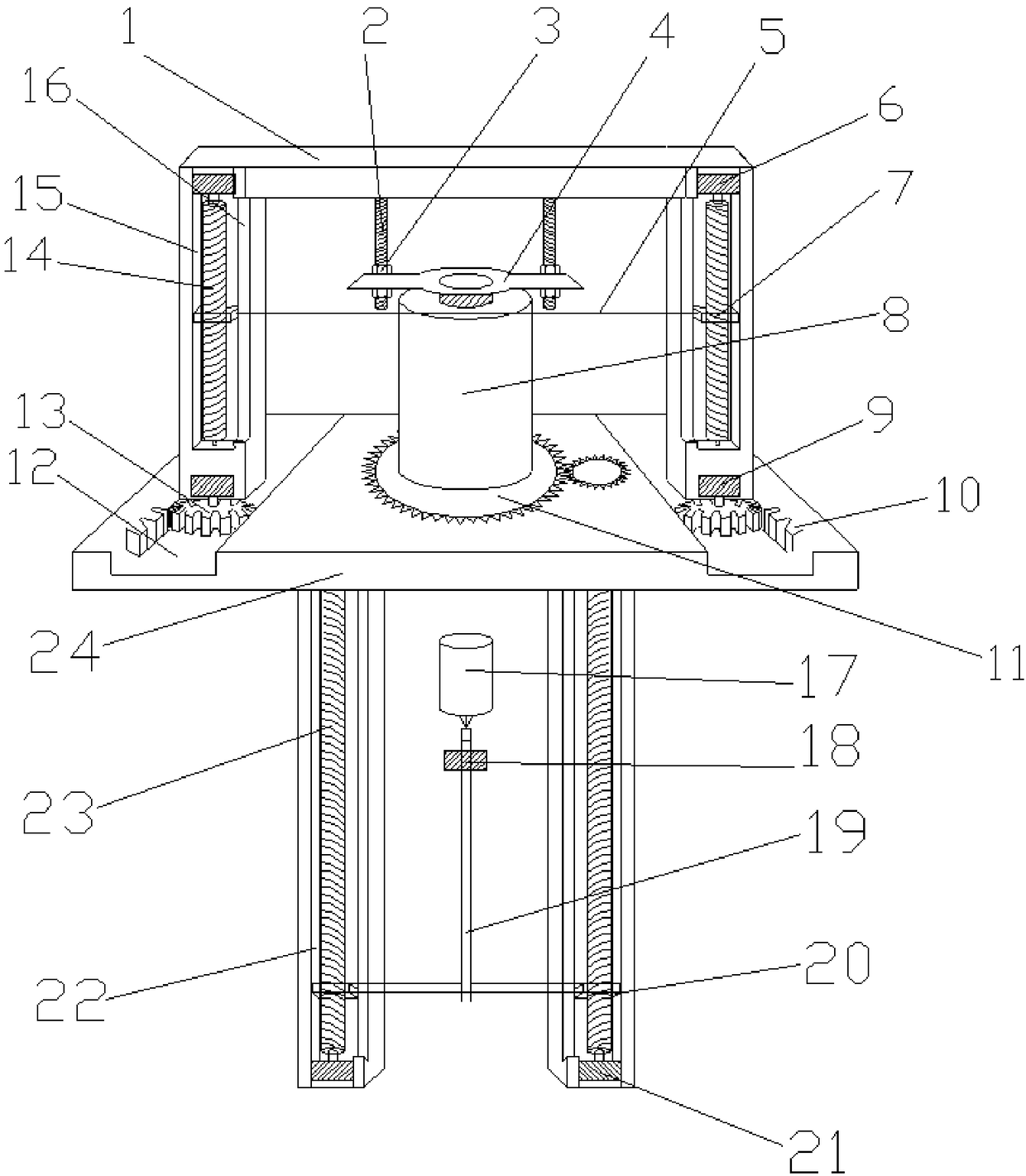

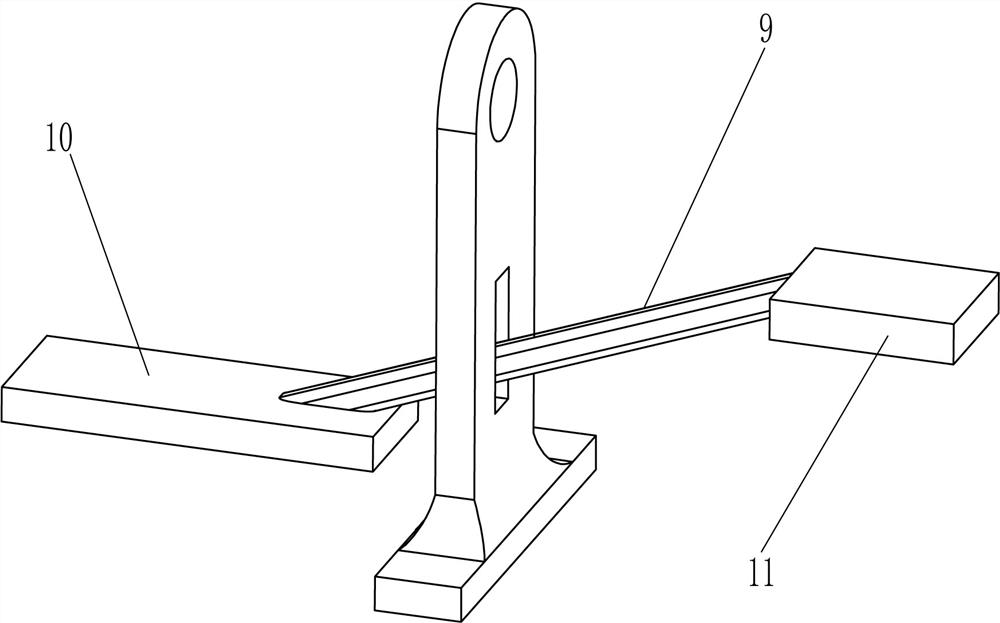

Semiautomatic hollow column soil sample making device

PendingCN108458905ASave energyShorten the timePreparing sample for investigationProgrammable logic controllerSemi automatic

The invention discloses a semiautomatic hollow column soil sample making device and belongs to the field of related geotechnical engineering. The invention provides the semiautomatic hollow column soil sample making device which comprises a fixing cover plate, a soil cutting iron wire, a middle partition plate, a soil cutting iron wire holder, a tray, a first stepper motor, a second stepper motor,a third stepper motor, a PLC (Programmable Logic Controller), a soil taking cylinder, and the like, wherein the first stepper motor, the second stepper motor and the third stepper motor are all connected with the PLC; two ends of the soil cutting iron wire are connected with the soil cutting iron wire holder; the iron wire can be moved up and down automatically; the holder can also be moved forwards and backwards automatically; the tray is used for controlling the rotation of a soil sample to be cut; the soil taking cylinder can be moved up and down and rotated. As a semiautomatic device, thedevice is very simple and convenient to operate and high in soil taking precision, the time and the labor can be greatly saved for experiment operators, and the problem of devices for semiautomatic hollow column soil sample making can be solved.

Owner:ZHEJIANG UNIV

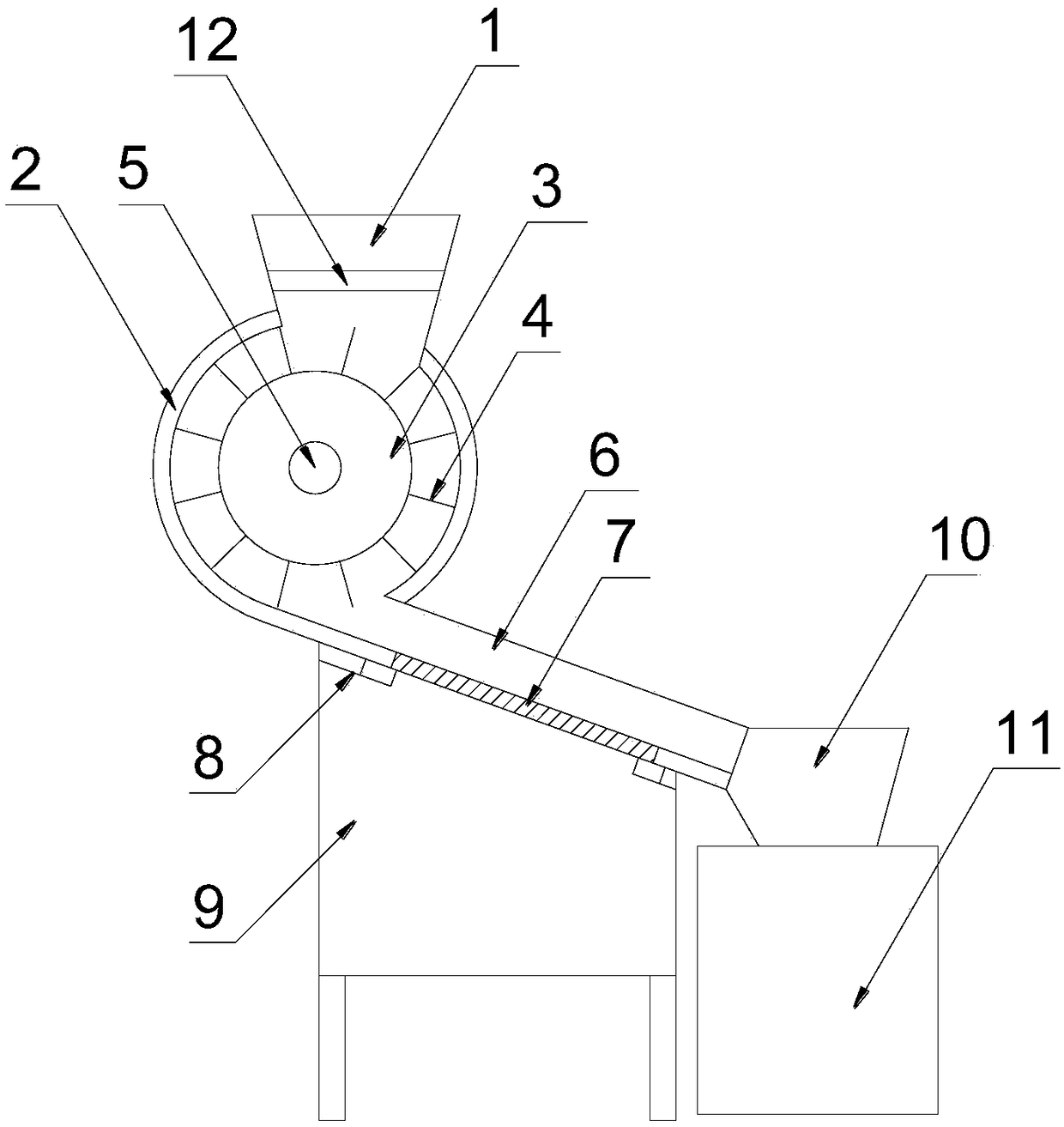

Feeding assembly of stone crusher

InactiveCN108580007AEasy to controlGood removal effectMagnetic separationGrain treatmentsEngineeringCrusher

The invention discloses a feeding assembly of a stone crusher. The feeding assembly of the stone crusher comprises a first feeding hopper, an annular feeding bin, a feed roll, material pushing plates,a discharging plate, a vibrating screen, a recovering box, a second feeding hopper and a crushing assembly. The first feeding hopper is fixed to the top of the annular feeding bin, and a discharge port of the first feeding hopper communicates with a feeding port of the annular feeding bin. The outer side of the first feeding hopper is fixedly provided with a magnetic ring. The middle of the annular feeding bin is provided with a rotating shaft. The periphery of the feed roll is evenly provided with the multiple sets of material pushing plates. The middle segment of the bottom of the discharging plate is provided with the vibrating screen. The two ends of the lower portion of the vibrating screen are provided with vibrating motors, and the recovering box is arranged below the vibrating screen. A discharge port of the discharging plate is connected with a feed port of the second feeding hopper, and the lower portion of the second feeding hopper is connected with the crushing assembly. According to the feeding assembly of the stone crusher, the material moving speed is uniform, the machining efficiency is improved, the service life of the equipment is guaranteed, the equipment is prevented from abrasion and damage, and the production cost is reduced for an enterprise.

Owner:来安县塔鑫建材有限公司

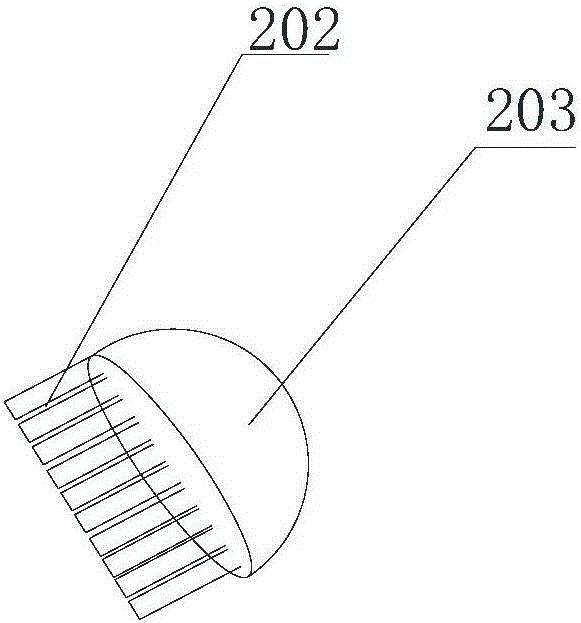

Multifunctional sprinkler

InactiveCN105214864AThere will be no problem that the hands are not long enough to washImprove experienceSpray nozzlesBristleEngineering

The invention provides a multifunctional sprinkler, and belongs to the field of shower goods. The multifunctional sprinkler is provided with a nozzle and a water outlet pipe, wherein the nozzle is communicated with the water outlet pipe. The multifunctional sprinkler further comprises a support frame and a bristle wheel for scrubbing and washing; the support frame is near the water outlet pipe, and is provided with a transmission mechanism; the bristle wheel is connected with the transmission mechanism; and the bristle wheel can vertically slide corresponding to the support frame. As the support frame and the bristle wheel are arranged, the bristle wheel is used for cleaning user bodies; the transmission mechanism on the support frame can drive the bristle wheel to vertically move corresponding to the support frame, so that the condition of incapability of cleaning some parts in place of users in the shower process due to short length of hands is improved; and meanwhile, the position of the bristle wheel is adjusted through the transmission mechanism, so that two hands of the users are liberated to prevent the aching pain of arms due to holding of a washing towel for washing in the shower process, and the experience of the users in the shower process is better.

Owner:肖琪钧

Scroll rolling device for educational display

InactiveCN107134176ASimple structureRealize the purpose of banner scrolling publicityMechanical appliancesReciprocating motionPropeller

The invention provides a scrolling banner device for educational display, which includes a base and a support column, two rotating bearings are fixedly installed on the base, the shaft of the rotating bearing is connected to a rotating drum, a belt is sleeved on the rotating drum, and a grid is fixedly installed on the top of the belt The top of the support column is fixedly installed with a support, the top shaft of the support is connected to the rotating shaft, the rear end of the rotating shaft is fixedly connected to the propeller, the front end of the rotating shaft is hinged to the left end of the first transmission rod, and the right end of the first transmission rod is hinged to the second The left end of the transmission rod and the right end of the second transmission rod are hinged on the front end of the translation block. A limit rod and a fixed rod are arranged on the translation block, and a push block is sleeved on the fixed rod. The transmission between the first transmission rod and the second transmission rod makes the translation block do linear reciprocating motion, and pushes the block to push the grill bar, and drives the belt to rotate, so that the purpose of banner scrolling publicity is well realized and energy is saved.

Owner:唐峰

Spraying method of wear-resistant coating of coating scraper and spraying mounting and clamping tool thereof

InactiveCN101886240BIncrease stiffnessImprove impact resistanceMolten spray coatingThermal sprayingWear resistant

The invention discloses a spraying method of a wear-resistant coating of a coating scraper and a mounting and clamping tool thereof, and the mounting and clamping tool consists of a workbench which is driven by a speed adjusting motor and rotates horizontally and a metal outer hoop and a tension inner hoop mounted on the workbench, wherein the tension inner hoop is provided with an opening, a puller bolt and a tension stop block are arranged at the opening, a ring of step is arranged on the inner wall of the metal outer hoop, and the height of the step is equivalent to the width of the coating scraper. When in spraying, the coating scraper is firstly mounted on the mounting and clamping tool, then a sand blasting gun is used for firstly carrying out sand blasting treatment on the coating scraper, and a plasma spraying gun is finally used for spraying the wear-resistant layer. The spraying method and the mounting and clamping tool can solve the technical problem of deformation of the coating scraper due to heating during the thermal spraying process.

Owner:SHANDONG UNIV OF SCI & TECH

Technique for film plating on powder surface and equipment thereof

InactiveCN101082120BEasy flipWith speed control functionVacuum evaporation coatingSputtering coatingVacuum pumpingMetallurgy

The present invention is powder surface coating process and apparatus. During coating powder, the powder is made to fall spirally in a vacuum environment and a homogeneous cladding is formed on the surface of the powder. The apparatus for coating powder includes one vacuum chamber, a vacuum film coating source, and a vacuumizing system. Inside the vacuum chamber, there are one turned conic rotaryhopper, one feeding chamber connected to the upper end of the hopper, and collecting chamber connected to its lower end. The vacuum film coating source mounted in the middle part inside the hopper has one speed adjustable motor for rotating the hopper. The present invention has great coating capacity and low running cost.

Owner:BYD CO LTD

Detection device for detecting hardness of color steel paint film

PendingCN114354418AHigh precisionUniform rotation speedInvestigating material hardnessMotor driveElectric machine

The invention discloses a detection device for detecting the hardness of a color steel paint film, the detection device comprises a base, a bottom plate, a first driving mechanism, a placement table, a support frame and a pencil holder, the bottom plate is movably arranged on the base, the first driving mechanism is arranged on the base and comprises a motor and a screw rod, the motor is arranged on the base, and an output shaft of the motor is in transmission connection with the screw rod; the bottom of the bottom plate is mounted on the screw, the placement table is movably arranged on the bottom plate, the supporting frame is arranged on the base, one end of the supporting frame extends to the position above the placement table, the pencil holder comprises a mounting block and a pencil, one end of the mounting block is mounted at the end, extending to the placement table, of the supporting frame, and an inclined plane is formed at the tail end of the other end of the mounting block. A through hole penetrating to the bottom of the mounting block is formed in the slope, one end of the pencil penetrates through the through hole to abut against the color steel of the containing table, the motor drives the screw to drive the bottom plate to reciprocate, and the pencil slides on the surface of the color steel for scribing. The color steel is uniformly scraped and slipped through the pencil, and the paint film hardness detection accuracy is improved.

Owner:ZHAOQING HONGWANG METAL IND

Ship-dedicated cargo hoist pin device

ActiveCN113387307AAvoid deflectionUniform rotation speedLifting devicesMarine engineeringStructural engineering

The invention discloses a ship-dedicated cargo hoist pin device which comprises a mounting frame connected with the body of a cargo hoist, a mounting plate fixedly connected to the bottom of the mounting frame, a gravity adjusting assembly, tow insertion teeth and two deflection limiting assemblies; the mounting plate is an arc-shaped bent plate, and an arc-shaped mounting groove is formed in the side, away from the mounting frame, of the mounting plate; the gravity adjusting assembly is arranged in the mounting groove in a limited mode, the gravity adjusting assembly comprises a gravity wheel, side wheels and a connecting plate, the gravity wheel is connected with the groove bottom of the mounting groove in a meshing mode through a clamping tooth assembly, the connecting plate is in an arc shape, and the two side wheels are rotatably installed at the two ends of the connecting plate and roll in the mounting groove; the two insertion teeth are symmetrically and fixedly connected to the two ends of the connecting plate; and the two deflection limiting assemblies are symmetrically mounted on the two sides of the mounting plate. It is guaranteed that articles are kept horizontal in the ship shaking process, falling damage of the articles is avoided, and meanwhile the transport efficiency of the articles is improved.

Owner:丹华海洋工程装备(南通)有限公司

An oil barrel rotary printing device

InactiveCN111619206BUniform rotation speedDoes not affect print qualityScreen printersScreen printingEngineeringMechanical engineering

The invention relates to a printing device, in particular to an oil barrel rotary printing device. The object of the present invention is to provide an oil drum rotary printing device which can make the rotation speed of the oil drum more uniform without affecting the printing quality. A rotary printing device for an oil drum, comprising a bottom plate, the upper side of the bottom plate is bolted with a frame and a slant plate, and both sides of the top of the bottom plate are rotatably installed with rollers for reducing friction; the bracket, the The number of brackets is at least two, which are respectively arranged on both sides of the top of the bottom plate, the rollers are located between the brackets on both sides, and the rollers and brackets are both located between the frame and the inclined plate. The invention drives the oil barrel to rotate through the printing assembly, and can print on the oil barrel, and replaces the manual rotation of the oil barrel with machinery, so that the oil barrel can rotate at a more uniform speed, thereby not affecting the printing quality.

Owner:夏伟

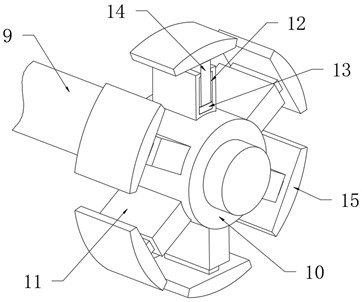

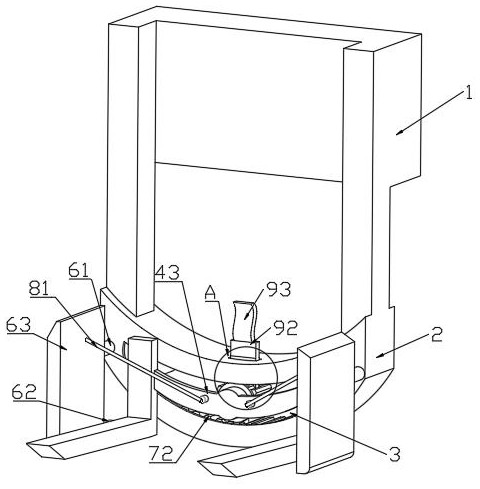

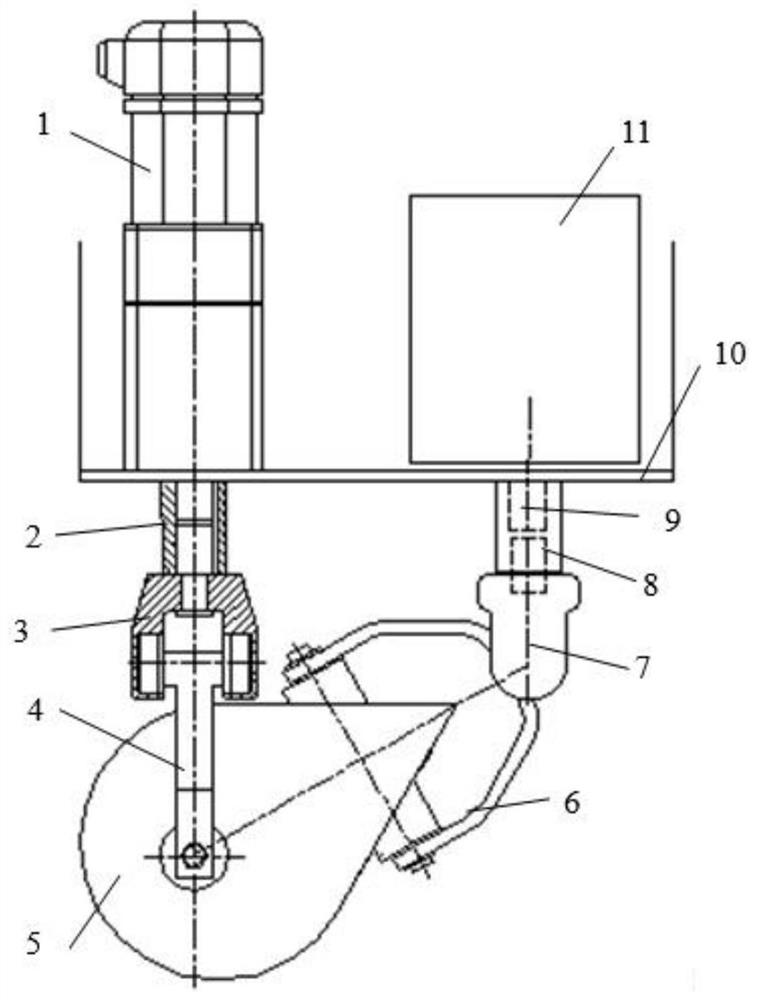

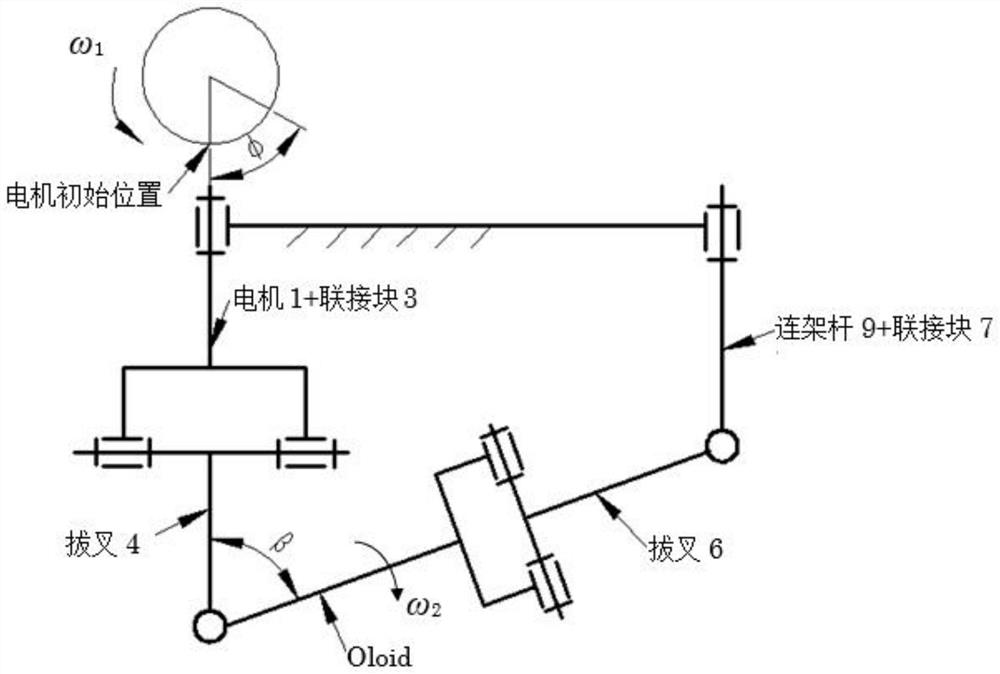

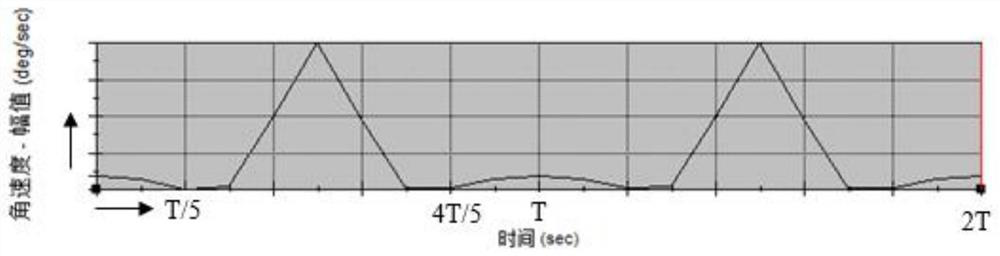

An anti-winding algae removal machine driven by double servo motors

ActiveCN109653178BSmooth rotationUniform rotation speedWater cleaningHarvestersCouplingControl engineering

A double-servo motor-driven anti-winding algae removing machine according to the present invention comprises a frame, first and second servo motors, first and second servo motor controllers, first and second sleeve couplings, The first and second coupling pins, the first and second coupling blocks, the first and second spacers, the first and second forks, the OLOID body, the first and second servo motors, the first and second servo motors The motor controllers are respectively arranged on the frame, the output shafts of the first and second servo motors respectively pass through the frame vertically, one end of the OLOID body is movably connected with the first fork, the other end is movably connected with the second fork, and the third A coupling block is movably connected with the first fork, the second coupling block is movably connected with the second fork, the first coupling pin and the second coupling pin are respectively movably connected with the first coupling block and the second coupling block, the first sleeve The barrel coupling is respectively connected with the first coupling pin and the output shaft of the first servo motor, and the second sleeve coupling is respectively connected with the second coupling pin and the output shaft of the second servo motor.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com