Coaxial double-blade submersible mixer for large fermentation tank

A technology for submersible mixers and fermenters, which is applied to specific-purpose bioreactors/fermenters, combinations of bioreactors/fermenters, biochemical instruments, etc. Large, fluid velocity energy dissipation and other issues, to achieve the effect of improving the effect of pushing flow, improving the stirring effect, and reducing the power consumption of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

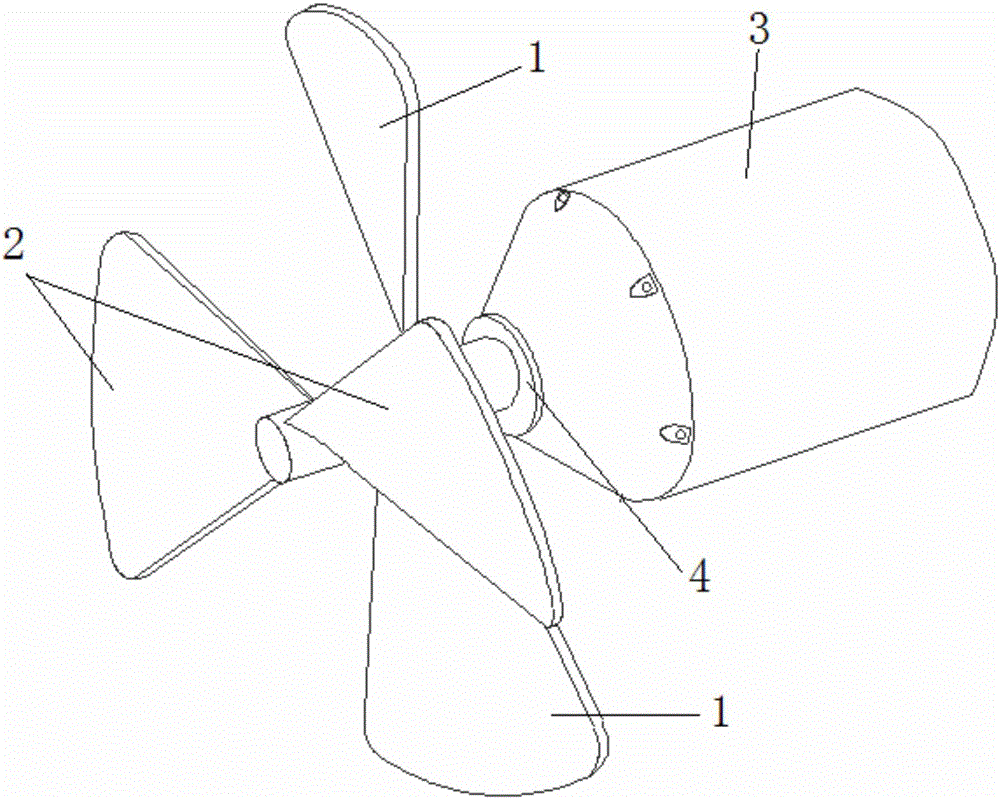

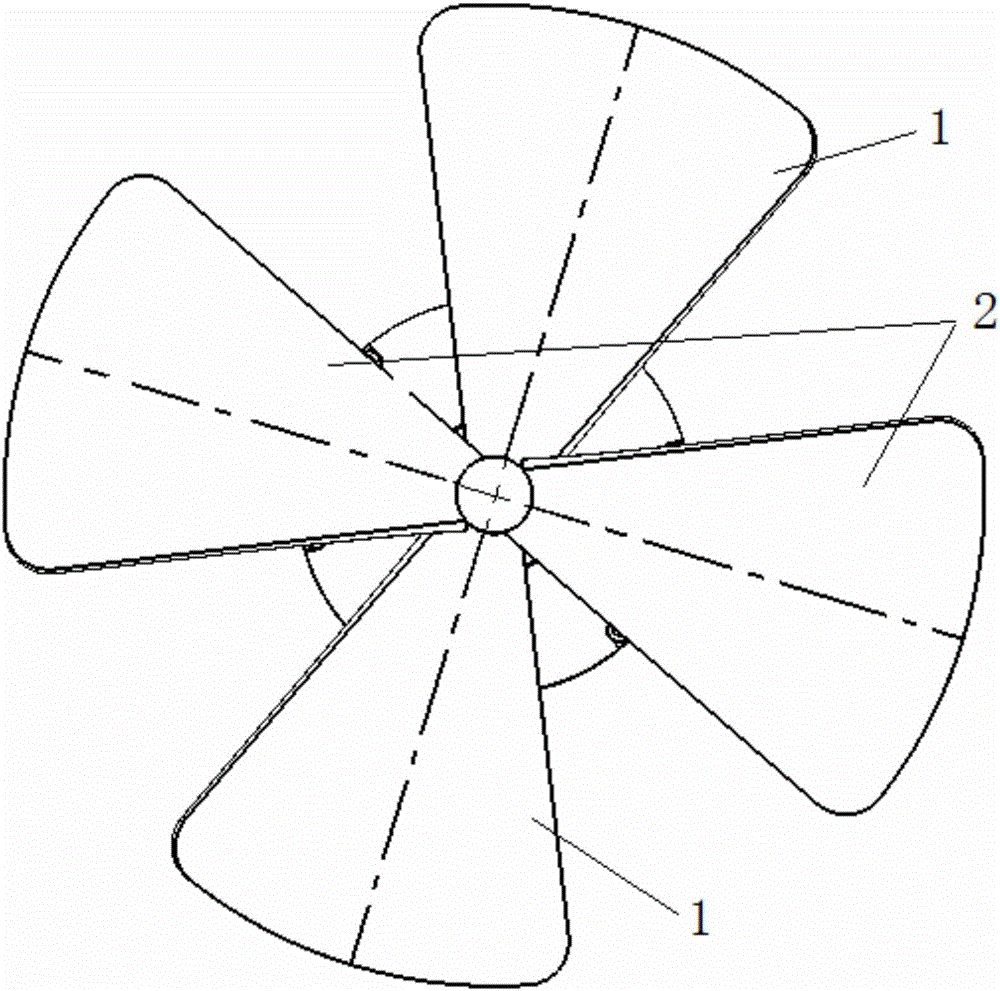

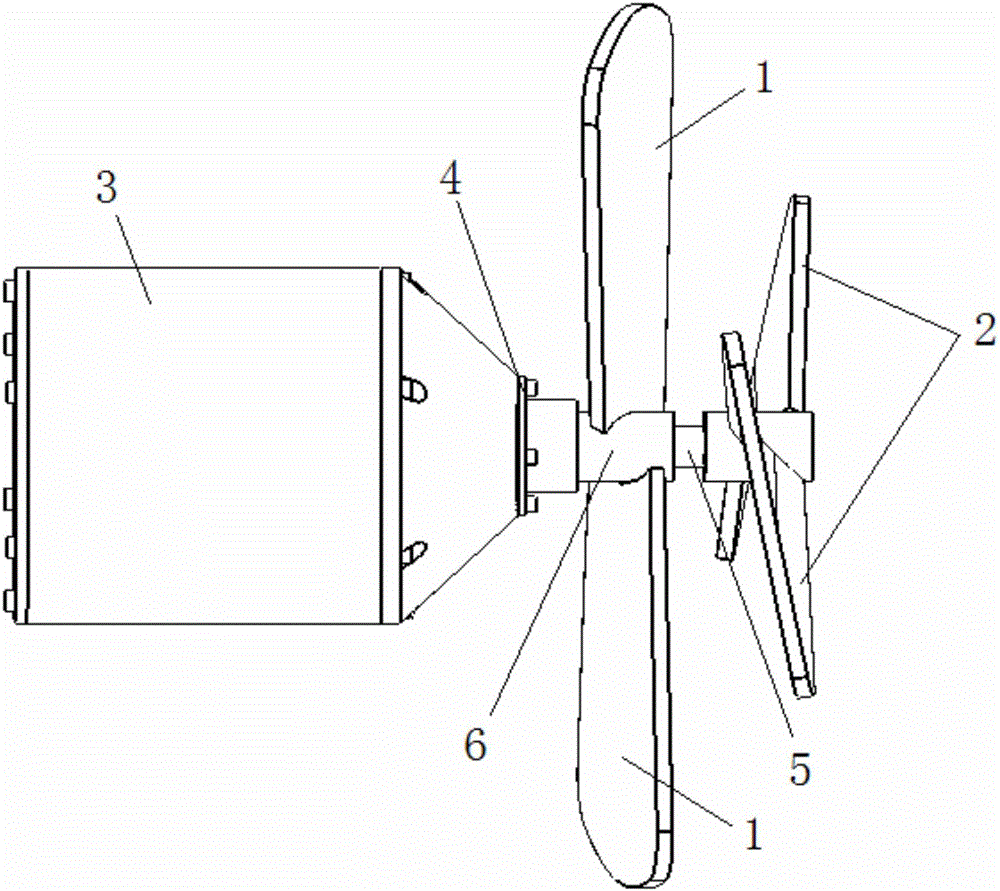

[0025] Such as Figure 1~6 Shown, the present invention comprises submersible motor 3, inner rotating shaft 5, outer rotating shaft 6, first bevel gear 11, second bevel gear 12 and two groups of paddles with opposite mounting directions, as Figure 6 As shown, the first bevel gear 11 and the second bevel gear 12 are arranged inside the submersible motor 3, and the rotor 13 edge inside the submersible motor 3 is provided with two sets of bevel teeth respectively connected with the first bevel gear 11 and the second bevel gear 12. The second bevel gear 12 meshes, and the first bevel gear 11 and the second bevel gear 12 are driven to rotate synchronously by the inner rotor 13 of the submersible motor 3, the outer shaft 6 is installed on the submersible motor 3, and the One end of the outer rotating shaft 6 positioned in the submersible motor 3 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com