Heat dissipation belt forming system

A heat dissipation belt and a pair of technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as complex structure, affecting product quality, inconvenient operation, etc., achieve uniform rotation speed, improve product quality, and ensure smooth production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

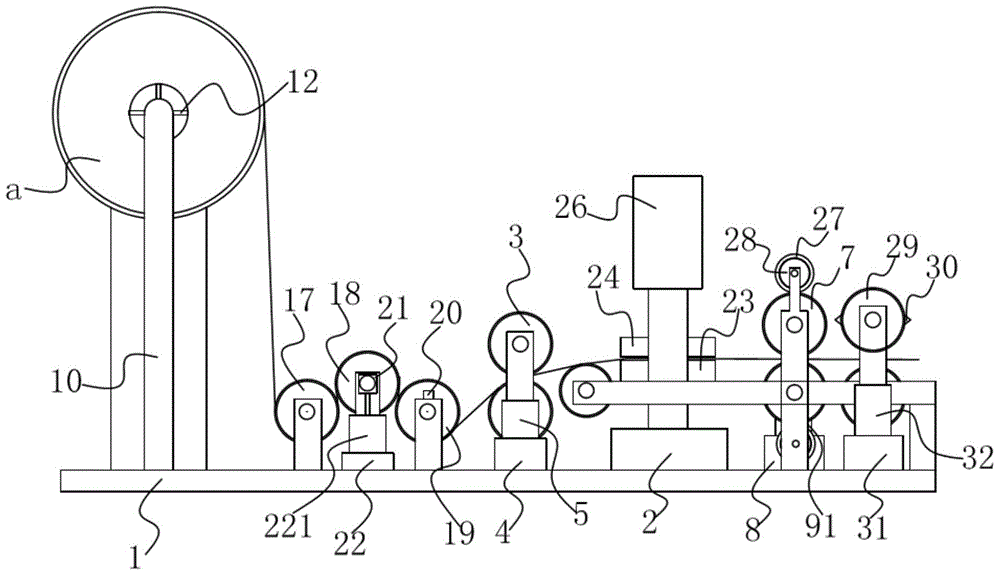

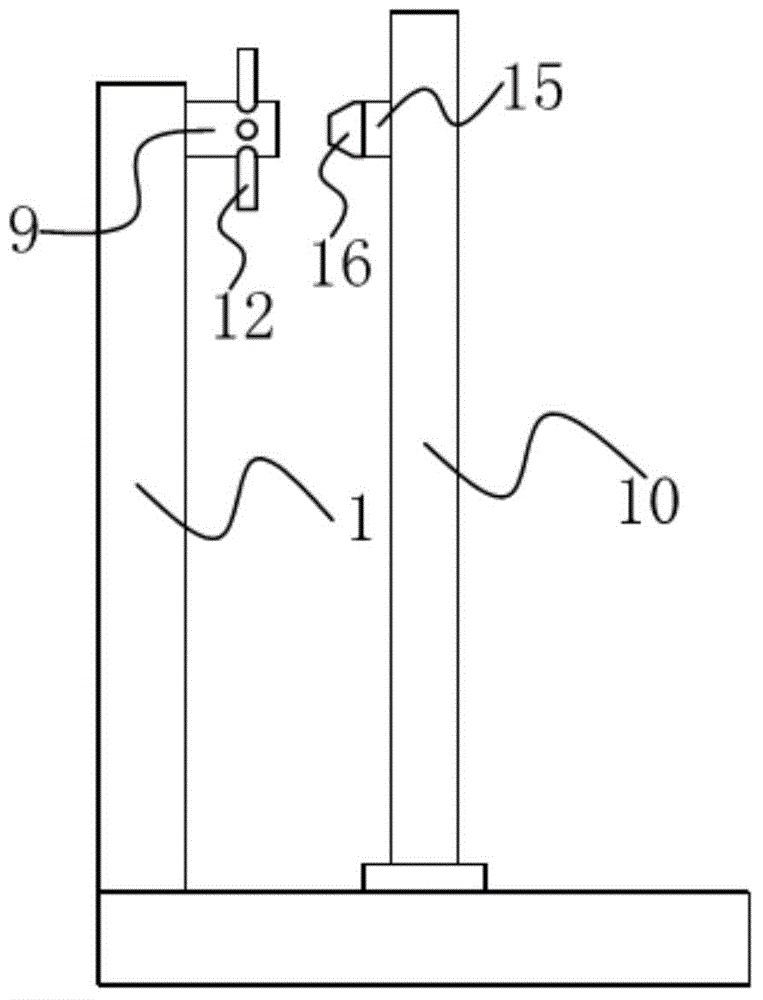

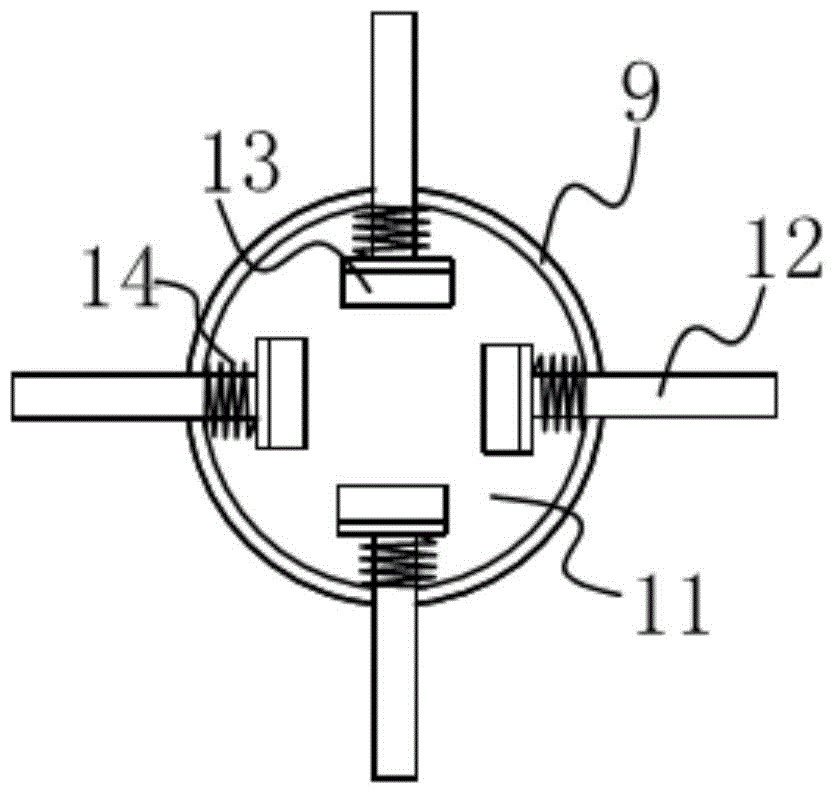

[0022] refer to Figure 1 to Figure 5 , the present invention comprises the uncoiling mechanism that is arranged on the frame 1 and is used for fixing the coil a of heat dissipation strip sheet and the feeding mechanism, straightening and flattening mechanism, rolling mechanism and programmable controller 2 that are sequentially located on the right side of the uncoiling mechanism. The feeding mechanism is provided with a tension roller for tensioning the heat dissipation belt sheet and a pair of conveying rollers 3 for conveying the heat dissipation belt sheet. The conveying roller 3 is connected with the drive motor 5 through the frequency converter 4. The roller is provided with a tension detection assembly, and the straightening and flattening mechanism is provided with an adjustment channel 6 which is parallel to the moving direction of the heat dissipation strip and allows the heat dissipation strip to pass through for straightening and flattening. The rolling mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com