Mechanism for coating oil on enameled wire by using liquid paraffin

A technology of liquid paraffin and enameled wire, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., to achieve uniform rotation speed and good oiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

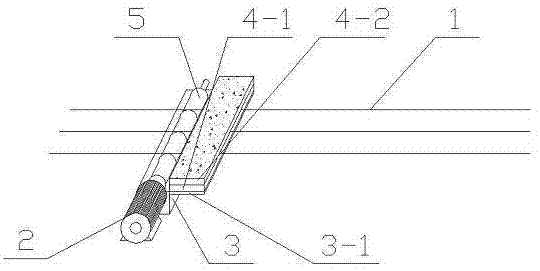

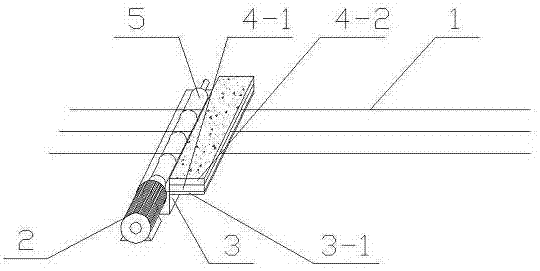

[0016] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0017] The invention designs an enameled wire oiling mechanism using liquid paraffin, which can use liquid paraffin to oil the enameled wire, so the enameled wire is more evenly oiled.

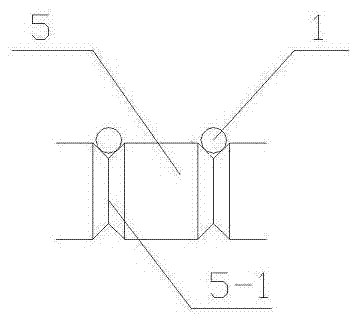

[0018] As a specific embodiment of this patent, the present invention provides a structural schematic diagram such as figure 1 An enameled wire oiling mechanism using liquid paraffin is shown, the oiling mechanism is arranged on the main body of the processing mechanism, and the oiling mechanism includes a motor 2, an oil tank 3, a felt and a rotating roller 5, and the rotating roller 5 is installed On the oil tank 3, the motor 2 is arranged on one side of the oil tank 3 and is connected with the rotating roller 5 to control the rotation of the rotating roller 5. There are 3-8 roller grooves 5-1 corresponding to the coated wire 1 to be coated on the rotating roller 5, The groove goes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com