A para-aramid fiber double surface oiling device

A para-aramid fiber, double-sided technology, which is applied in the field of oiling devices on both sides of para-aramid fiber, can solve problems such as difficulty in ensuring uniform oiling, difficulty in adjusting the position of the oil nozzle flexibly, and inability to apply to the fineness range, etc., to achieve guaranteed consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

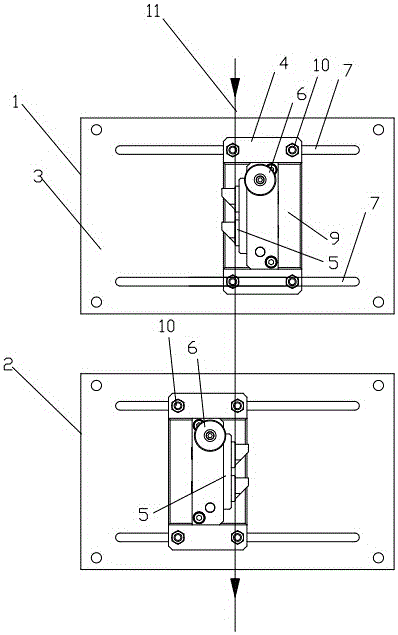

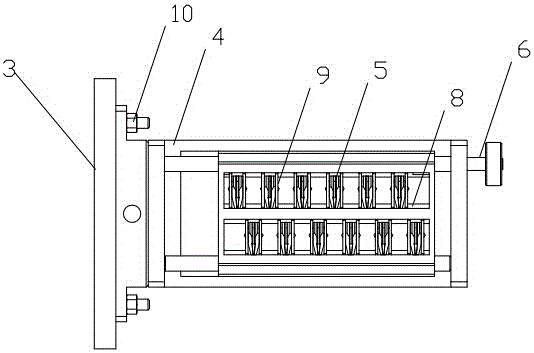

[0022] A double-side oiling device for para-aramid fibers, characterized in that it includes a first oiling mechanism 1 and a second oiling mechanism 2, and the first oiling mechanism 1 and the second oiling mechanism 2 are from top to bottom Arranged vertically, the first oiling mechanism 1 and the second oiling mechanism 2 both include a fixed plate 3, an oil nozzle holder 4, an oil nozzle 5 and a guide rod 6, and the fixed plate 3 connects with the oil nozzle through the fixed plate slide rail 7 The fixed seat 4 is connected, and the oil nozzle fixed seat 4 is provided with a guide rod 6, and the oil nozzle slide rail 8 is arranged on the guide rod 6, and a plurality of oil nozzle fixing blocks 9 are arranged on the oil nozzle slide rail 8, and each oil nozzle fixing block 9 is provided with an oil nozzle 5; the oil nozzle fixing block 9 is fixed on the oil nozzle slide rail 8 through a top screw; the guide rod 6 is connected with the oil nozzle fixing seat 4 through the bol...

Embodiment 2

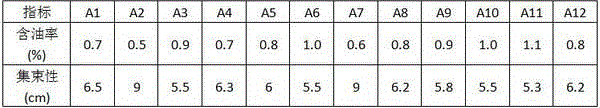

[0024] A para-aramid fiber double-face oiling device includes a first oiling mechanism 1 and a second oiling mechanism 2, and the first oiling mechanism 1 and the second oiling mechanism 2 are vertically arranged from top to bottom, so The first oiling mechanism 1 and the second oiling mechanism 2 both include a fixing plate 3, a nozzle fixing seat 4, a nozzle 5 and a guide rod 6, and the fixing plate 3 is connected with the nozzle fixing seat 4 through a fixing plate slide rail 7, The oil nozzle fixing seat 4 is provided with a guide rod 6, the oil nozzle slide rail 8 is provided on the guide rod 6, and a plurality of oil nozzle fixing blocks 9 are arranged on the oil nozzle slide rail 8, and each oil nozzle fixing block 9 is provided with a The oil nozzle 5; the oil nozzle fixing block 9 is fixed on the oil nozzle slide rail 8 through the top screw; the guide rod 6 is connected with the oil nozzle fixing seat 4 through the bolt 10 on it; the oil nozzle fixing seat 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com