An anti-winding algae removal machine driven by double servo motors

A dual-servo motor and servo motor technology, applied in the field of machinery, can solve the problems of small exchange of nutrient gas in water body, secondary pollution of water area, increased maintenance cost and difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

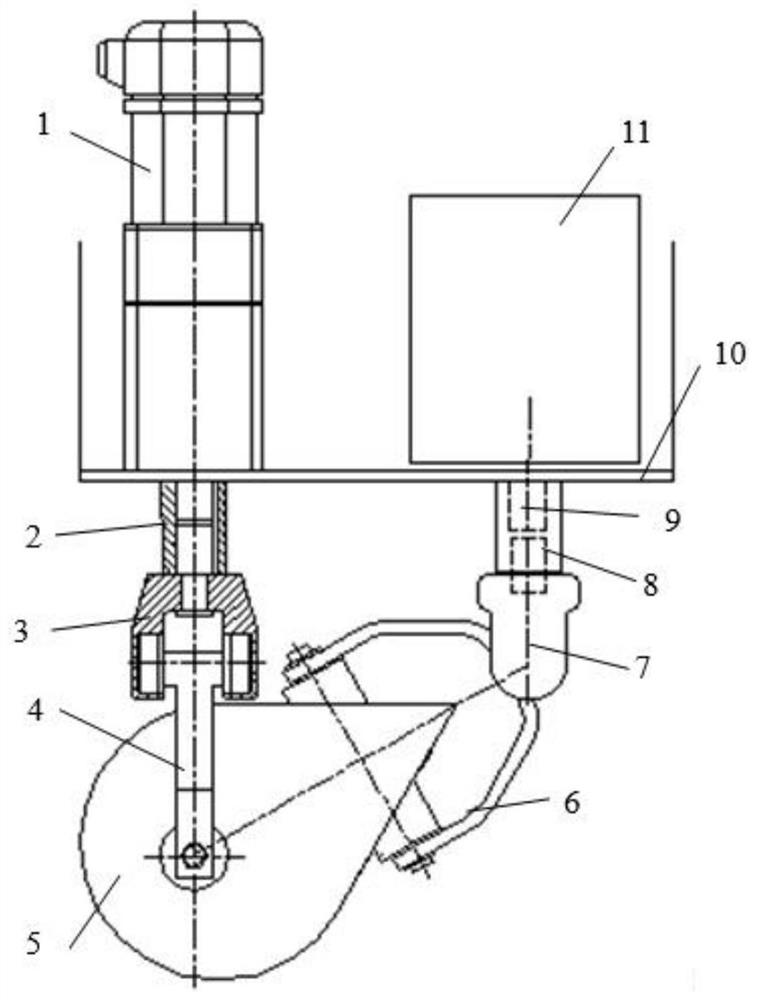

[0034] Take the single servo motor OLOID algae removal machine as an example, such as figure 1 As shown, the OLOID algae removal machine includes servo motor 1, sleeve coupling 2, connection block 3, fork 4, OLOID body 5, fork 6, connection block 7, sleeve coupling 8, and connecting rod 9 , frame 10, servo motor controller 11.

[0035] Technical scheme of the present invention comprises the steps:

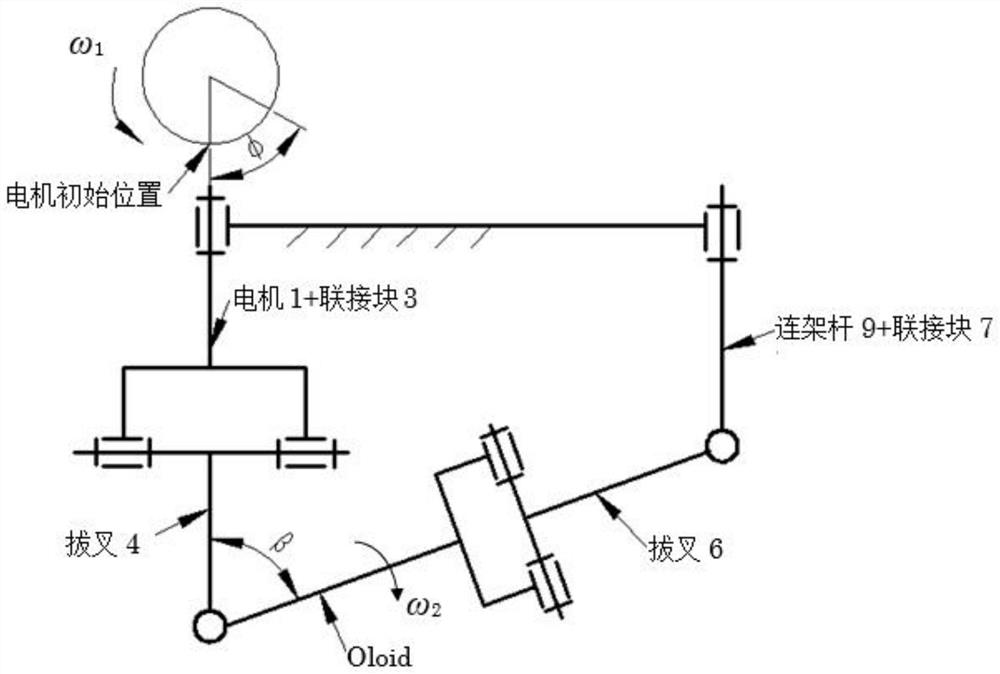

[0036] 1. Study the working principle and structural composition of OLOID algae removal machine, deduce and summarize the motor input speed ω of OLOID 1 with the output velocity ω of the OLOID volume 2 relationship between.

[0037] The OLOID body is a special geometric structure discovered by the German mathematician Paul Schatz in 1929. OLOID cleverly uses the principles of fluid mechanics to avoid resistance in the largest range during fluid motion, forming a unique fluid trajectory. An Oloid body is formed by overlapping convex hull skeletons formed by two circles with equa...

Embodiment 2

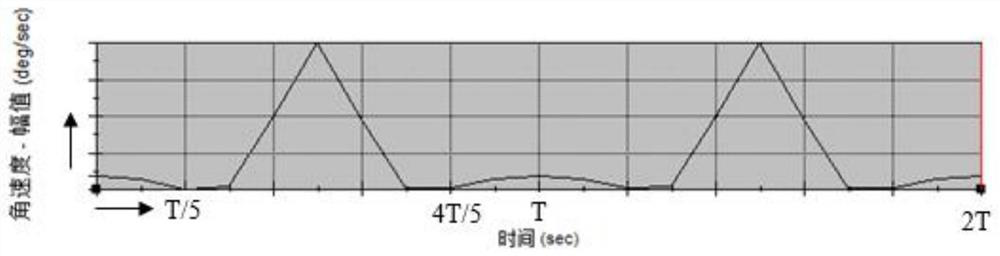

[0057] In this embodiment, an anti-winding OLOID algae removing machine driven by a servo motor is designed by using the optimal design method for the minimum speed of the anti-winding algae removing machine in the first embodiment.

[0058] In this embodiment, the servo motor is selected as the driving device, and when the rotation reaches the minimum speed position, the minimum speed is increased to prevent winding. By setting the servo motor at a constant speed, the output speed of the OLOID is obtained by calculation analysis and computer simulation methods, and the servo motor is analyzed and debugged so that the algae remover can compensate the rotation speed when a certain speed reaches the minimum position, and as much as possible Keep the rotation at a constant speed to ensure that the rotation speed reaches the level that can effectively grind the seaweed. The redesign calculates the center distance of the oloid, increases the exchange volume of the water body, impro...

Embodiment 3

[0072] In this embodiment, an anti-winding OLOID algae removing machine driven by double servo motors is designed by using the optimal design method for the minimum speed of the anti-winding algae removing machine in the first embodiment.

[0073] In this embodiment, two servo motors are selected, and the speed can be controlled through the characteristics of the servo motors. When the minimum speed appears when the oloid rotates at a certain position, the speed of rotating to this position is increased through the control of the servo system. Because the servo motor is a typical closed-loop feedback system, the reduction gear set is driven by the motor, and its terminal, the output end, drives a linear proportional potentiometer for position detection. The potentiometer converts the rotation angle coordinates into a proportional voltage and feeds it back to the control circuit board. , the control circuit board compares it with the input control pulse signal, generates a corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com