Spraying method of wear-resistant coating of coating scraper and spraying mounting and clamping tool thereof

A wear-resistant coating and scraper technology, applied in coating, metal material coating process, melting spray plating, etc., can solve problems such as coating scraper deformation, achieve the speed of delaying temperature rise, simple structure, and prolong spraying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is an example of a coating blade with a spraying length of 3 meters, a width of 100 mm, and a thickness of 0.381 mm. Adopt plasma spraying process to prepare AT13 (Al2O3-13%TiO2) wear-resistant coating, its specific implementation is as follows:

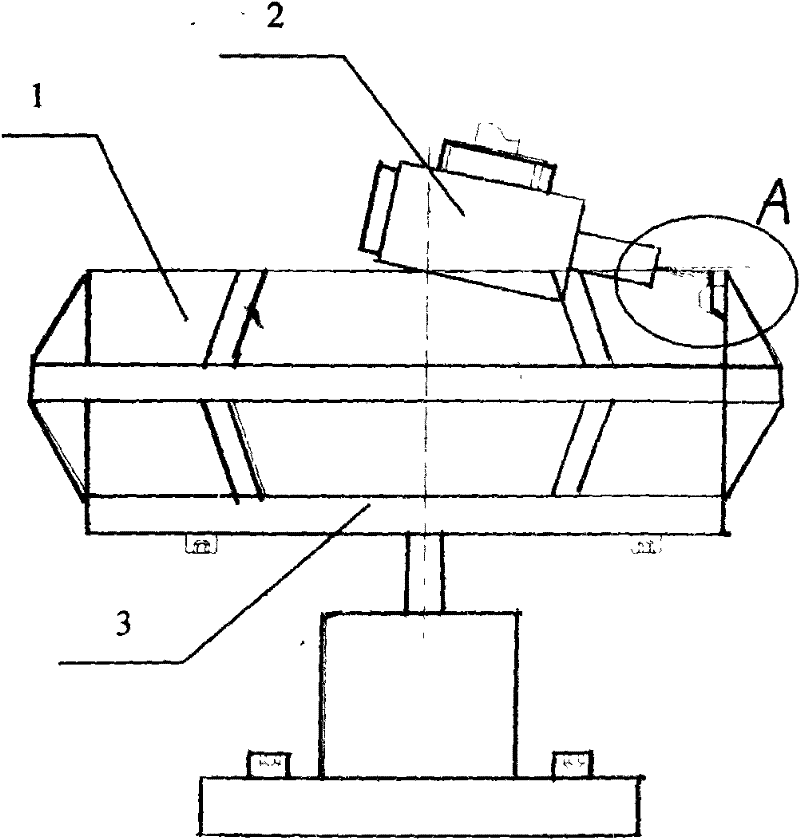

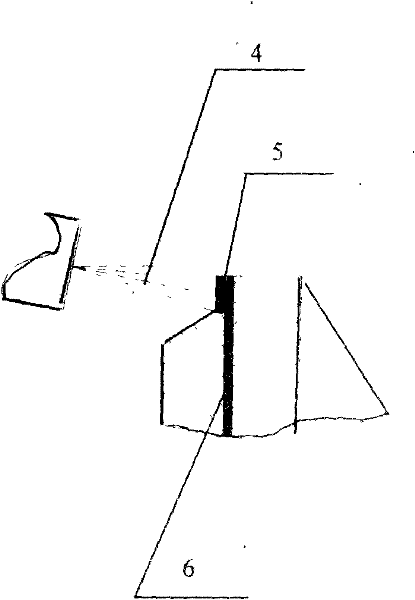

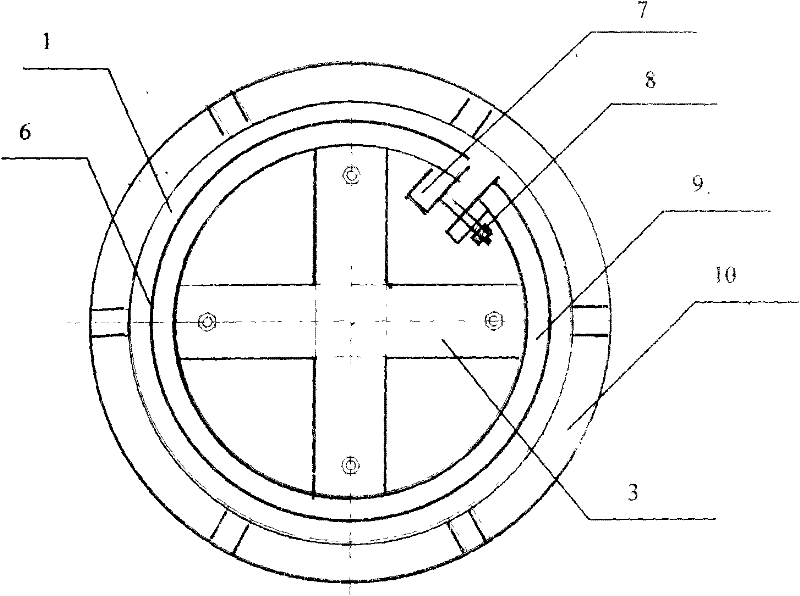

[0022] The first step: according to the size of the scraper according to figure 1 , figure 2 The shown components are processed with fixtures. Specifically, it is composed of a horizontally rotating workbench 3 driven by a speed-regulating motor, a metal outer hoop 1 mounted on the workbench 3, and an inner tension hoop 9; wherein the inner tension hoop 9 is provided with an opening, and the opening is provided with There are jacking bolts 8 and tension stoppers 7, and the inner wall of the metal outer hoop 1 is provided with a circle of steps, the height of which is equal to the width of the coating scraper, and the height of the tension inner hoop 9 is lower than the height of the steps, and the lower dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com