An oil barrel rotary printing device

A technology for printing devices and oil drums, which is applied in the direction of rotary printing machines, printing machines, printing machines, etc., which can solve the problems of uneven rotation speed of oil drums, affect printing quality, and poor markings, etc., and achieve the effect of uniform speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

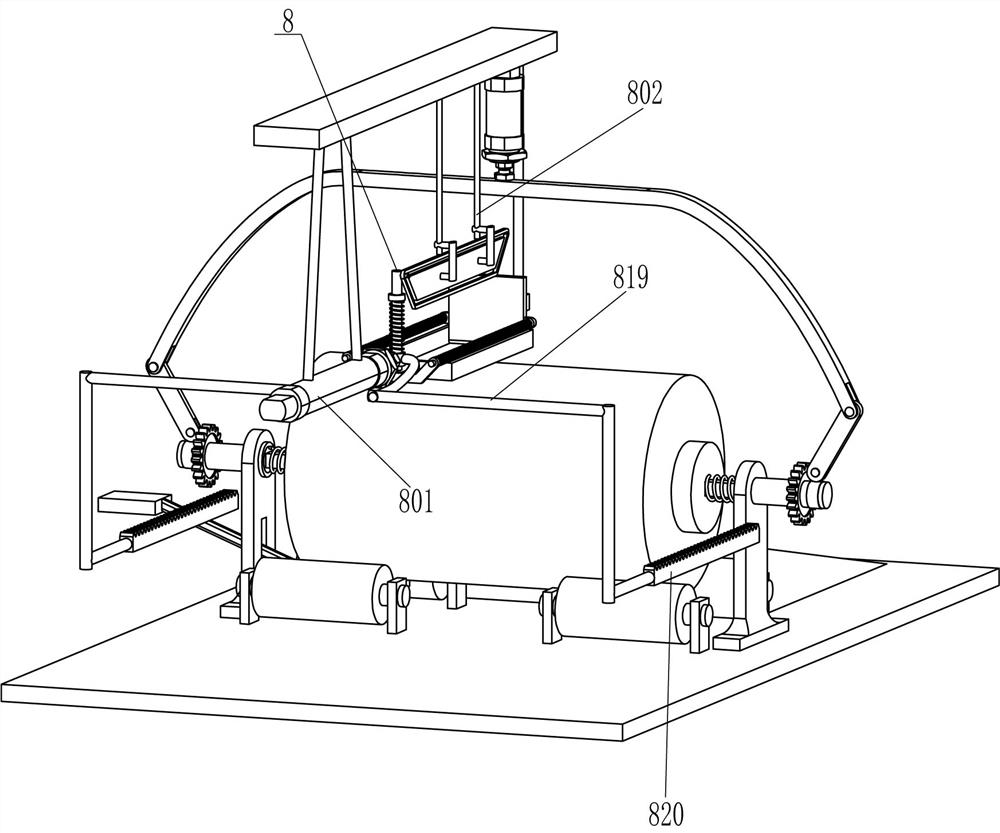

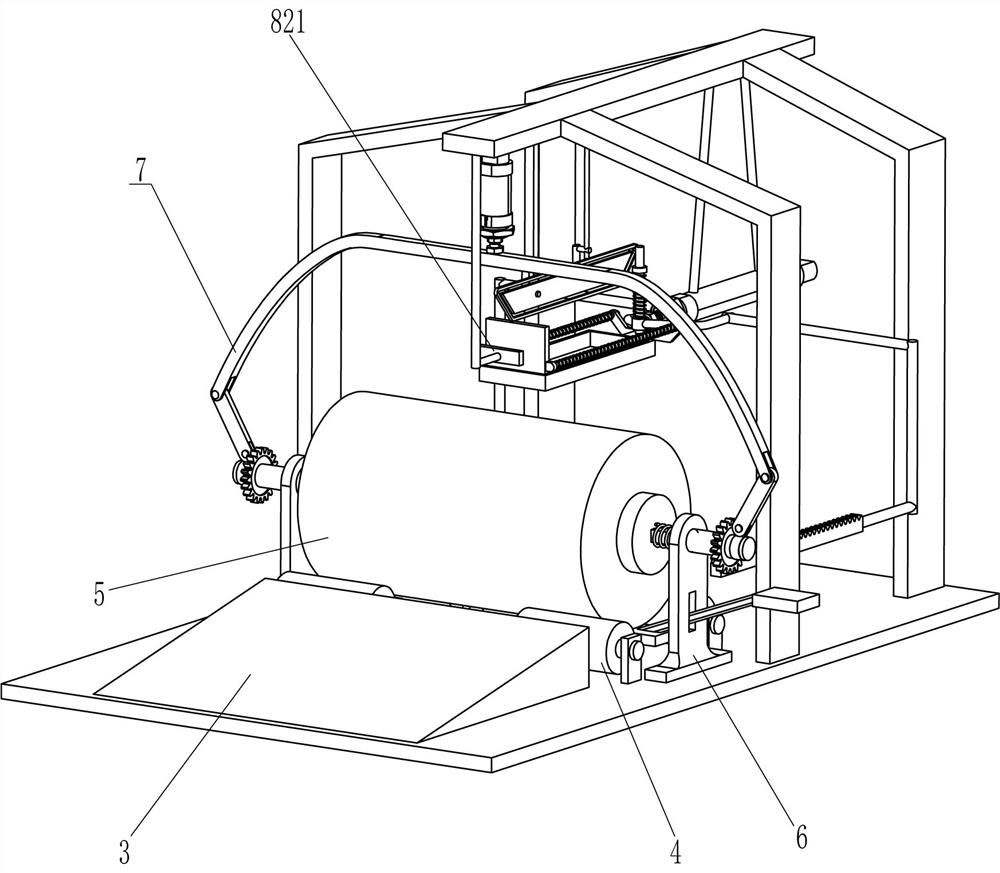

[0024] A drum rotary printing device, such as Figure 1-6 As shown, it includes base plate 1, frame 2, inclined plate 3, roller 4, bracket 6, clamping assembly 7 and printing assembly 8, the top left side of base plate 1 is installed with frame 2 by bolts, and the top right side of base plate 1 is A slant plate 3 is connected by bolts, and two rollers 4 are rotatably installed on the front and rear sides in the middle of the top of the bottom plate 1, and brackets 6 are installed on the front and rear sides of the top of the bottom plate 1 through bolts, and the rollers 4 are located between the two brackets 6. Clamping assembly 7 is installed on 6, and printing assembly 8 is installed on frame 2.

[0025] The clamping assembly 7 includes a first cylinder 701, a special-shaped rod 702, a connecting rod 703, a hollow sleeve 704, a push sleeve 705, a rectangular rod 706, a rubber clip 707 and a first spring 708, and the top right side of the frame 2 passes through The first cyl...

Embodiment 2

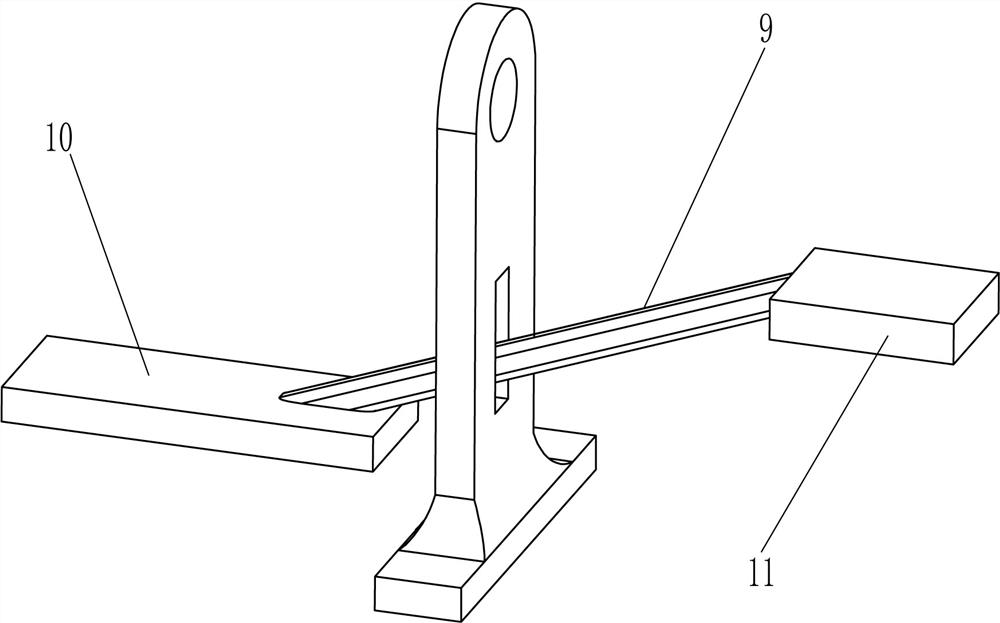

[0031] On the basis of Example 1, such as Figure 7 As shown, it also includes a rotating rod 9, a push plate 10 and a pedal 11. The rear support 6 is connected with a rotating rod 9, the front end of the rotating rod 9 is connected with a push plate 10, and the rear end of the rotating rod 9 is connected with a pedal 11. .

[0032] People can step on the pedal 11 downwards, and the pedal 11 drives the push plate 10 to swing upwards through the rotating rod 9, and the oil drum 5 on the roller 4 is tilted, so that people can take off the oil drum 5 that has been printed conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com