Oil cooling speed regulation type cooling system

A cooling system and speed regulation technology, applied in cooling/ventilation devices, casings/covers/supports, electrical components, etc., can solve the problems of cooling system temperature accumulation, lack of speed regulation function, etc., and achieve convenient speed regulation function , Simple structure, avoid the effect of temperature accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

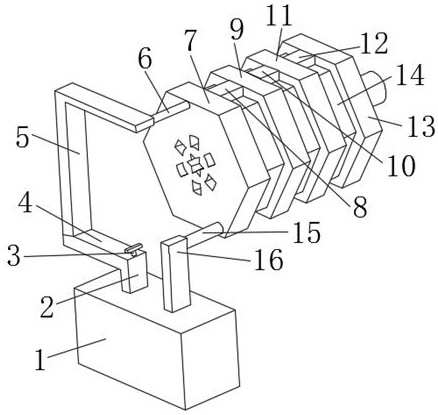

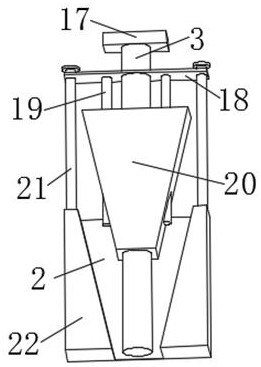

[0018] Embodiment one, by figure 1 and figure 2 Provided, the present invention includes a fuel tank 1, a first connecting pipe 2 is installed on the top side of the fuel tank 1, a second connecting pipe 4 is connected to the top of the first connecting pipe 2, a deflector 22 is fixed on the bottom of the first connecting pipe 2, and a deflector 22 is fixed on the bottom of the first connecting pipe 2. A screw rod 21 is installed on the top of the flow plate 22, the top of the screw rod 21 is connected with a top plate 18, a guide rod 19 is fixed on one side of the bottom end of the top plate 18, the middle part of the top plate 18 is sleeved with a rotating shaft 3, and the top of the rotating shaft 3 is fixed with a rotating rod 17, and the middle part of the rotating shaft 3 The outside is sleeved with a trapezoidal block 20, the top side of the second connecting pipe 4 is connected with a third connecting pipe 5, the top of the third connecting pipe 5 is fixed with an oil...

Embodiment 2

[0019] Embodiment two, on the basis of embodiment one, by figure 1 and figure 2 Given, a water pump is installed at the bottom of the oil tank 1 to provide sufficient oil pressure.

Embodiment 3

[0020] Embodiment three, on the basis of embodiment one, by figure 1 and figure 2 It is given that the two guide rods 19 are distributed symmetrically, which is convenient for uniform stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com