Planetary magnetic meshing flexible speed-regulating transmission device

A transmission device and flexible adjustment technology, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficulty in meeting the requirements of variable speed and speed regulation transmission, improve work efficiency and reliability, and avoid damage. , easy to change the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

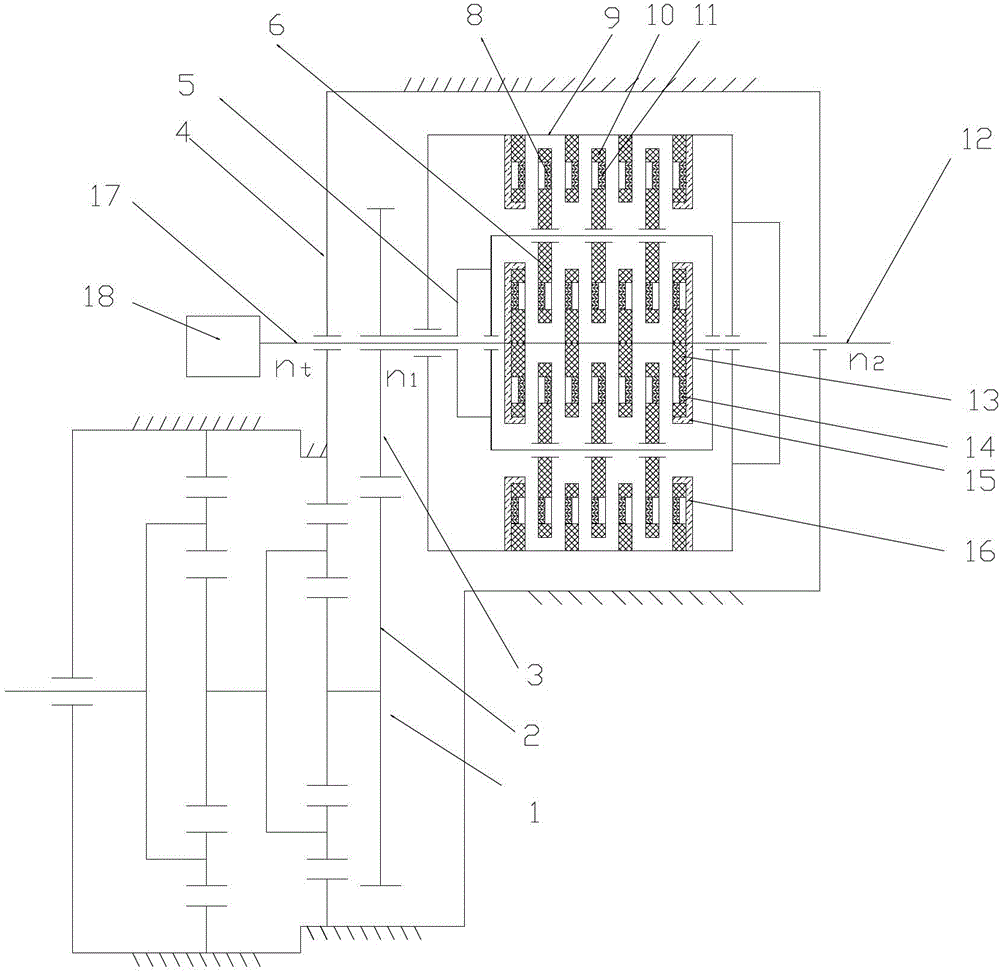

[0031] Such as figure 1 As shown, a planetary magnetic meshing flexible speed-regulating transmission device includes a casing 4, a planetary magnetic wheel assembly, an outer magnetic coil assembly, a central magnetic wheel assembly, a speed-regulating motor 18, and a front gearbox 1. The planetary magnetic wheel Assembly, outer magnetic ring assembly, and center magnetic wheel assembly are all arranged in the casing 4, and the described speed-regulating motor 18 is connected with the center magnetic wheel assembly, and is arranged outside the casing, and the described front gear box 1 and the planetary magnetic wheel Components are connected and disposed outside the enclosure. Corresponding bearings are provided between the planetary magnetic wheel assembly, the central magnetic wheel assembly, and the outer magnetic ring assembly, and corresponding bearings are provided between the central magnetic wheel assembly, the outer magnetic ring assembly, and the housing, so that t...

Embodiment 2

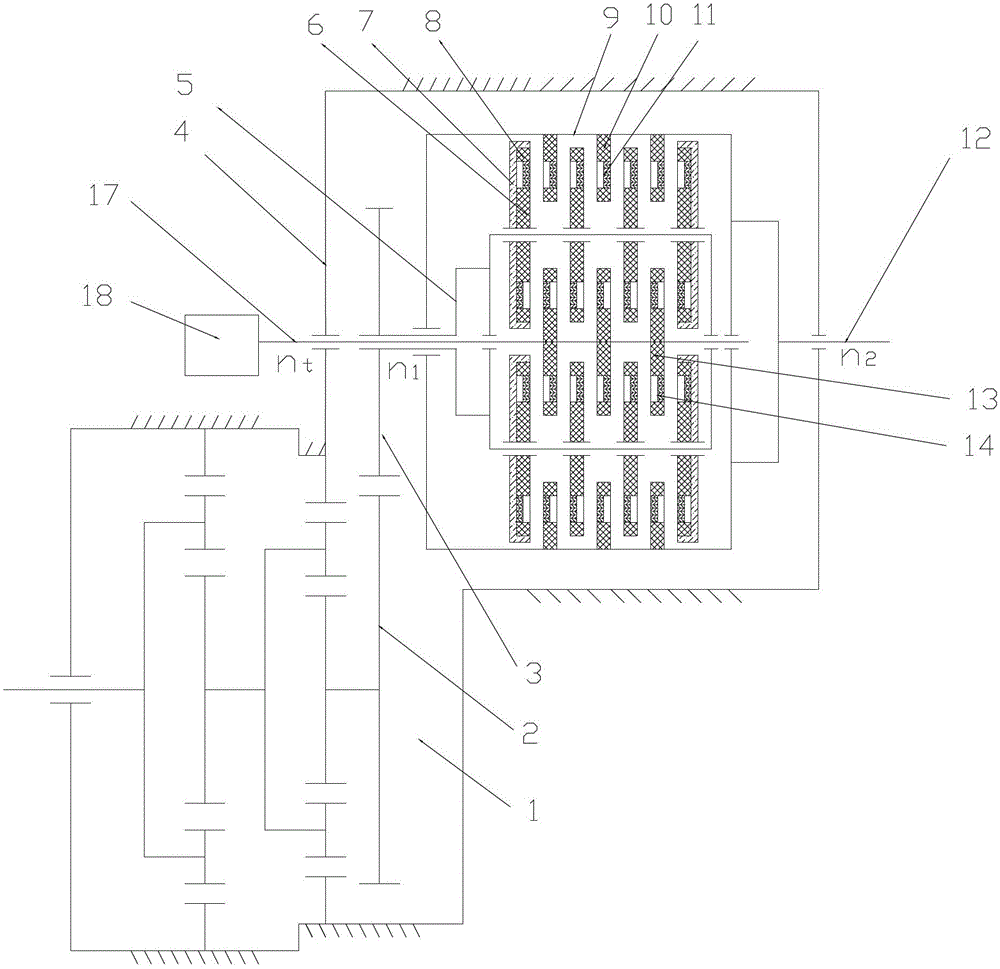

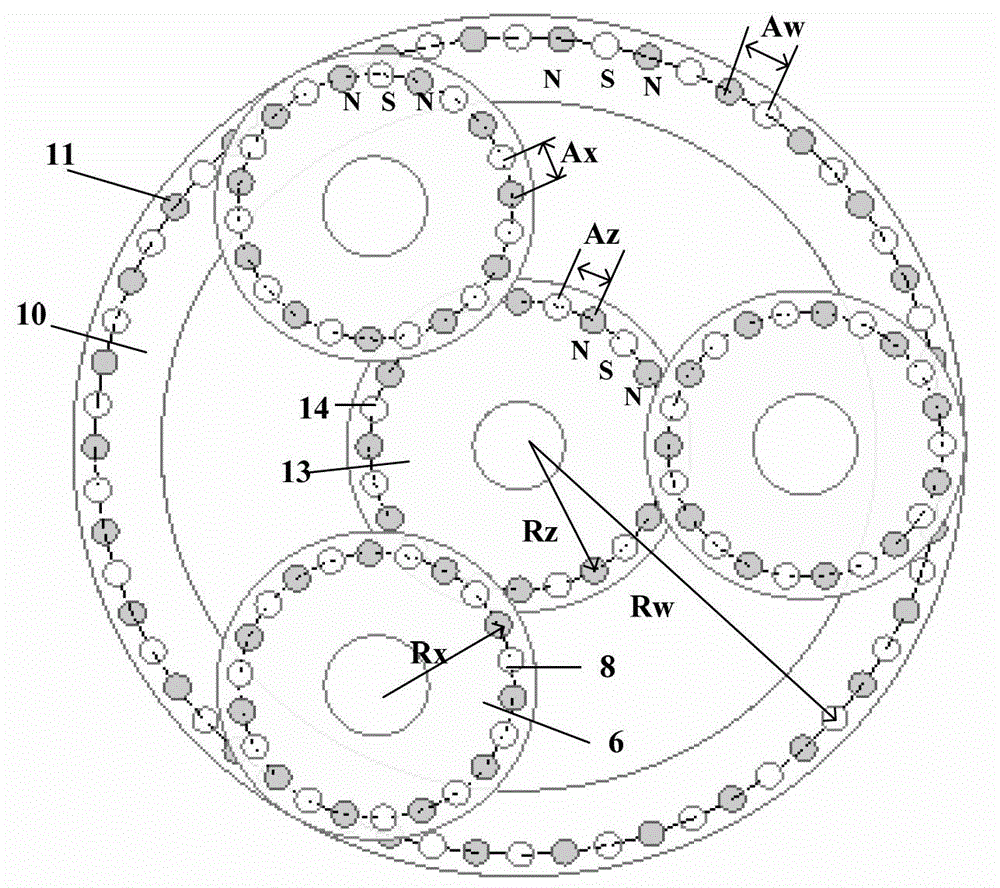

[0042] This embodiment is basically the same as Embodiment 1, the difference is: as figure 2 , Figure 4 As shown, the present embodiment is provided with four sets of symmetrically distributed planetary magnetic wheel sets, and the relationship between the axial arrangement number W of the outer magnetic ring, the axial arrangement number X of the planetary magnetic wheels and the axial arrangement number Z of the central magnetic wheel is X=W+ 1=Z+1, W:X:Z=3:4:3. Such as figure 2 As shown, the staggered arrangement in this embodiment is provided with a planetary magnetic yoke 7 on the outermost planetary magnet wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com