Speed-adjustable planetary magnetic meshing flexible transmission device

A flexible transmission and magnetic meshing technology, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficult to meet the requirements of variable speed and speed-adjustable transmission, so as to improve work efficiency and reliability, speed regulation The effect of small power and wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

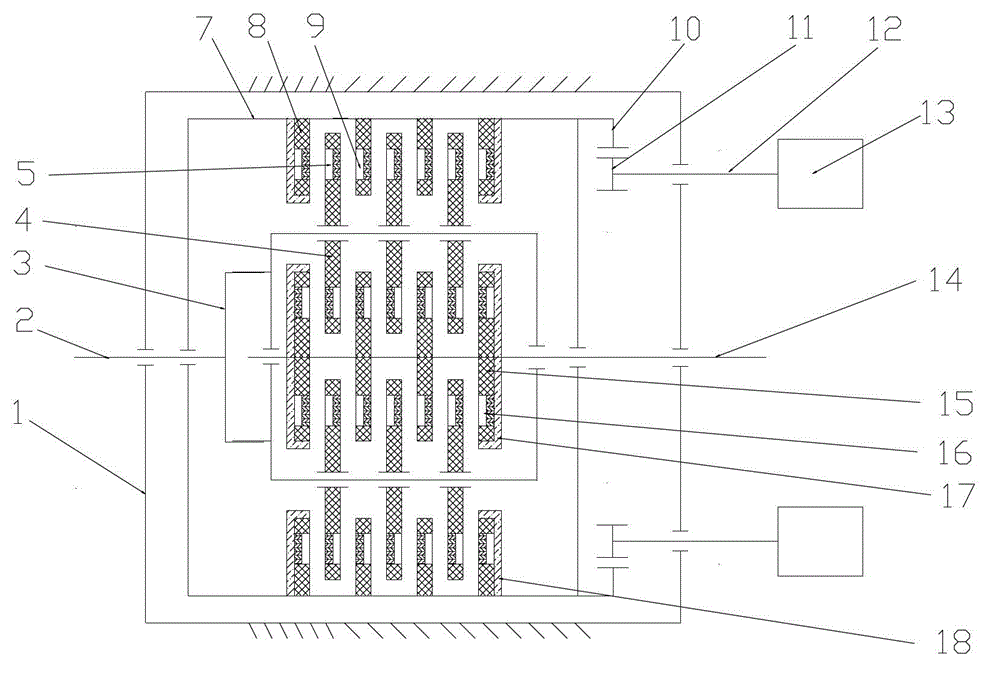

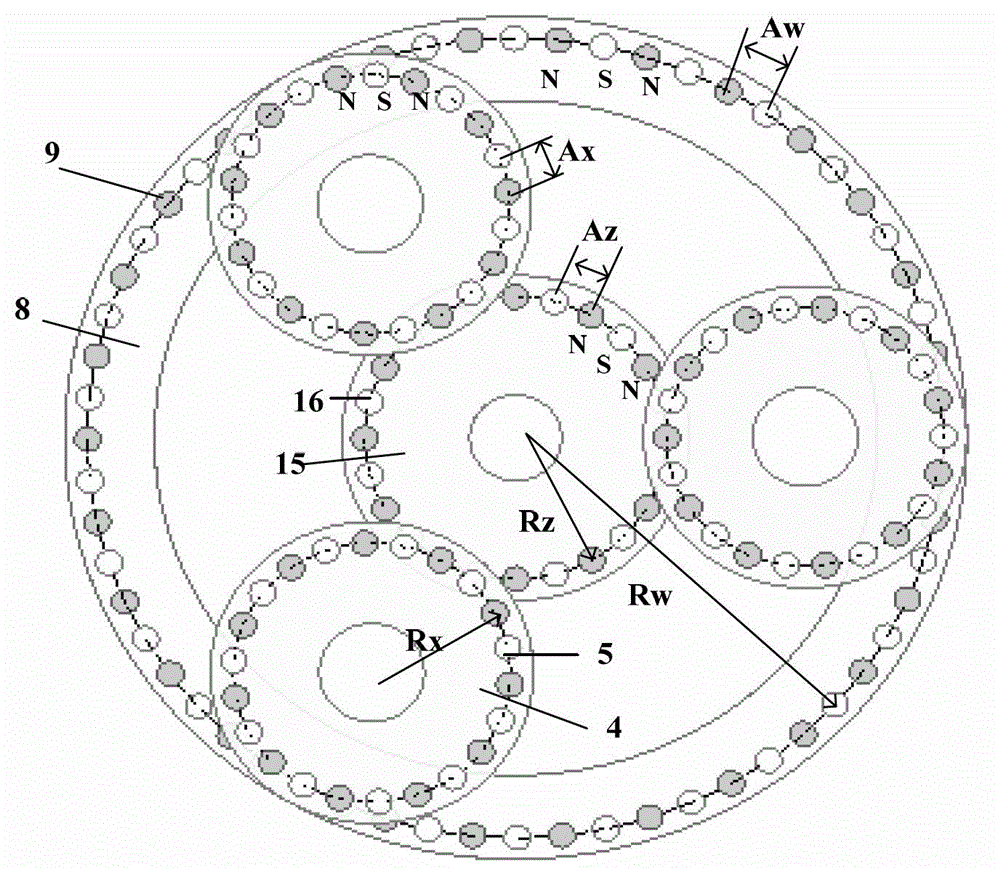

[0031] Such as figure 1 As shown, an adjustable speed planetary magnetic meshing flexible transmission device includes a casing 1, a planetary magnetic wheel assembly, an outer magnetic ring assembly, a central magnetic wheel assembly and an outer ring speed regulating assembly. The planetary magnetic wheel assembly, the outer magnetic coil assembly and the central magnetic wheel assembly are all arranged in the casing 1, and the outer ring speed regulating assembly is connected to the outer magnetic coil assembly. Corresponding bearings are provided between the planetary magnetic wheel assembly, the central magnetic wheel assembly, the outer magnetic ring assembly and the casing, so that the planetary magnetic wheel assembly, the central magnetic wheel assembly, and the outer magnetic ring assembly can all rotate, forming three concentric rotating bearings .

[0032] The described planetary magnetic wheel assembly comprises a planetary carrier shaft extension 2, a planetary ...

Embodiment 2

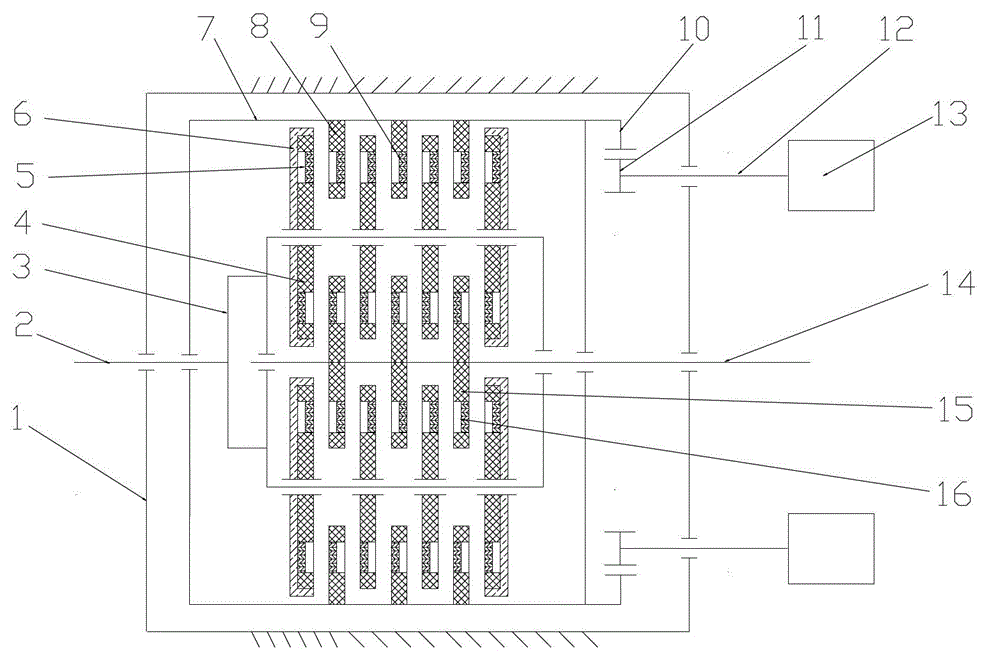

[0044] This embodiment is basically the same as Embodiment 1, the difference is: as figure 2 , Figure 4 As shown, the present embodiment is provided with four sets of symmetrically distributed planetary magnetic wheel sets, and the relationship between the axial arrangement number W of the outer magnetic ring, the axial arrangement number X of the planetary magnetic wheels and the axial arrangement number Z of the central magnetic wheel is X=W+ 1=Z+1, W:X:Z=3:4:3. Such as figure 2 As shown, in this embodiment, planetary magnetic yokes 6 are arranged on the outermost planetary magnetic wheels in a staggered arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com