Hanging-type handheld vibrating plastering machine

A suspension type, plastering machine technology, applied in construction, building structure and other directions, can solve the problems of changing the physical and chemical properties of mortar, increasing the cost of construction materials, complex plastering machine structure, etc., to achieve good man-machine integration, construction operation. Intuitive and accurate, reducing the effect of falling ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

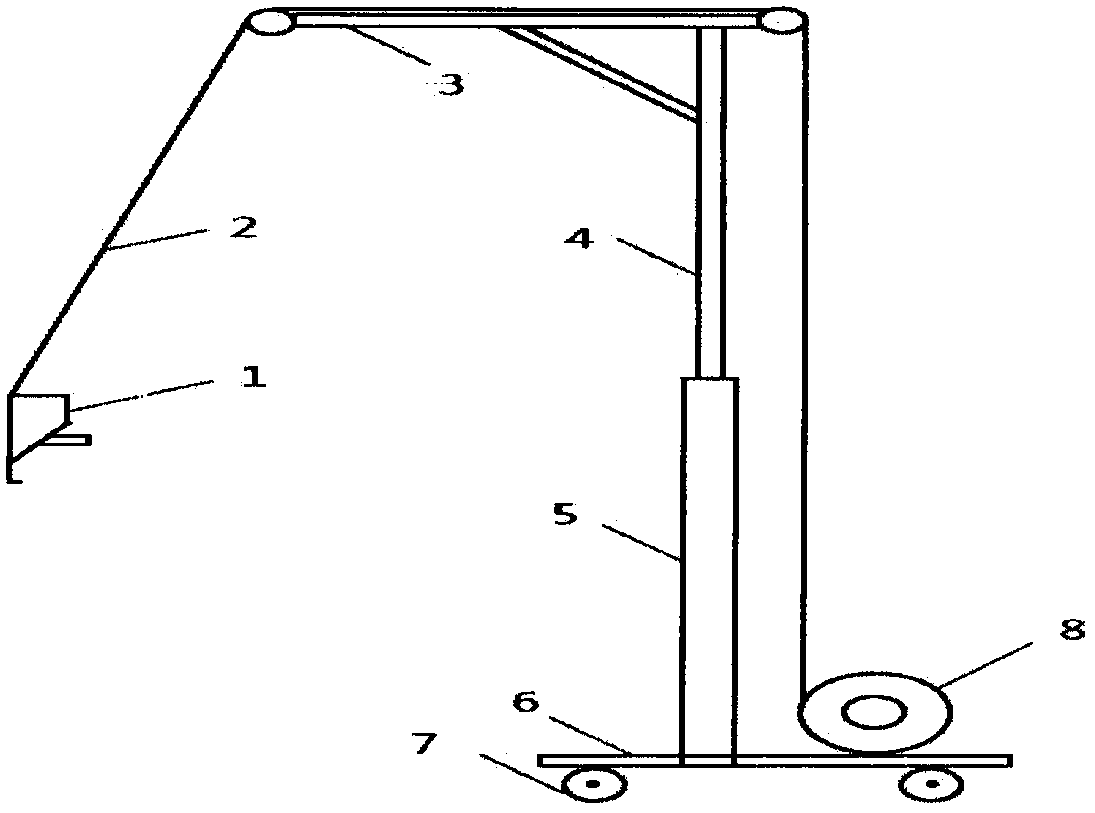

[0028] Attached below figure 1 Further detail with example: hanger is made up of base 6, column 5, boom 3, and base 6 is provided with mobile roller 7 and column 5, and column 5 links to each other with boom 3. The boom 3 can rotate in the horizontal direction with the column 5 as the axis. The column 5 of the hanger is made up of at least two vertical pipes with different cross-sections and plugged together. By vertically pulling up the inner tube 4 with a small cross-section, the height of the column 5 and the boom 3 is adjusted. The hand-held vibrating plasterer 1 is connected to the hanger and the electric hoist 8 installed on the hanger with a speed regulating function through the sling 2 .

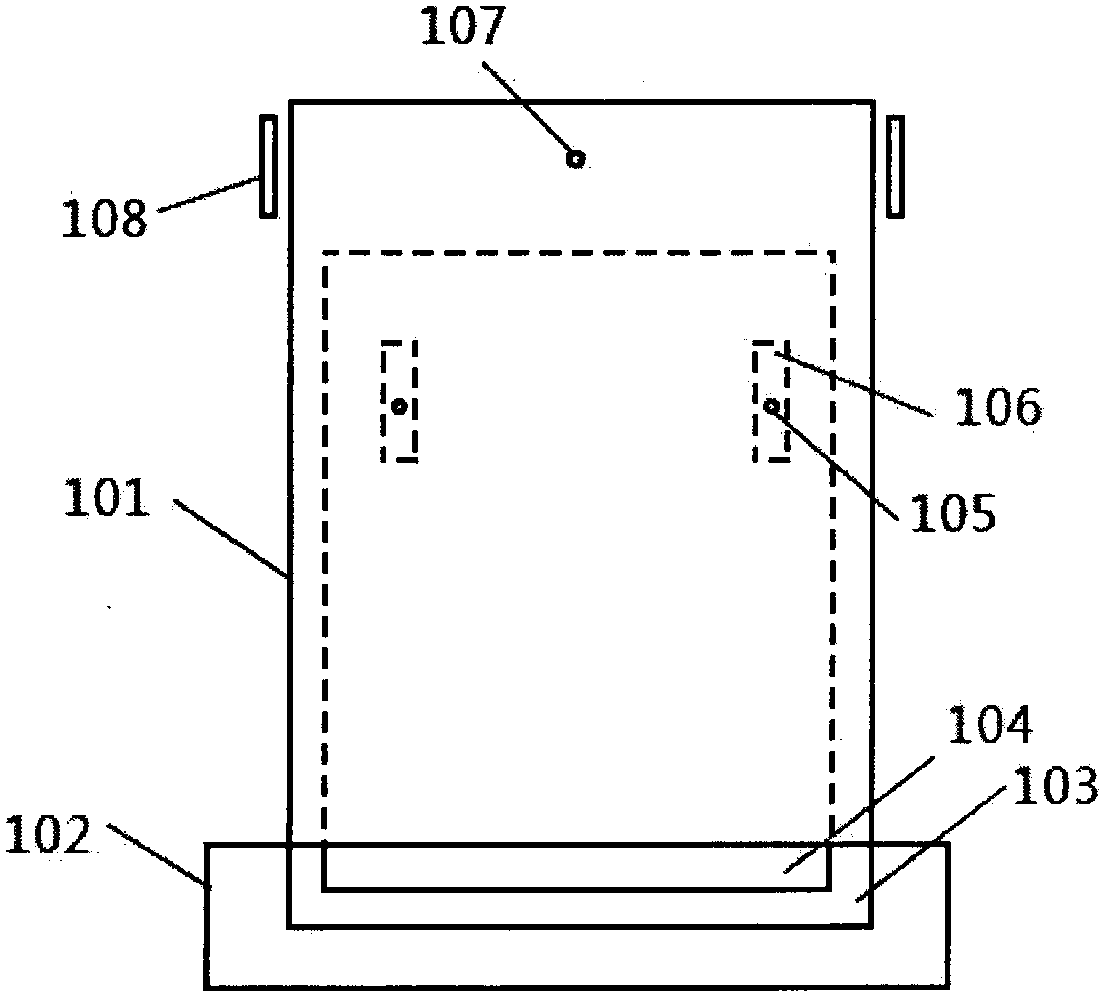

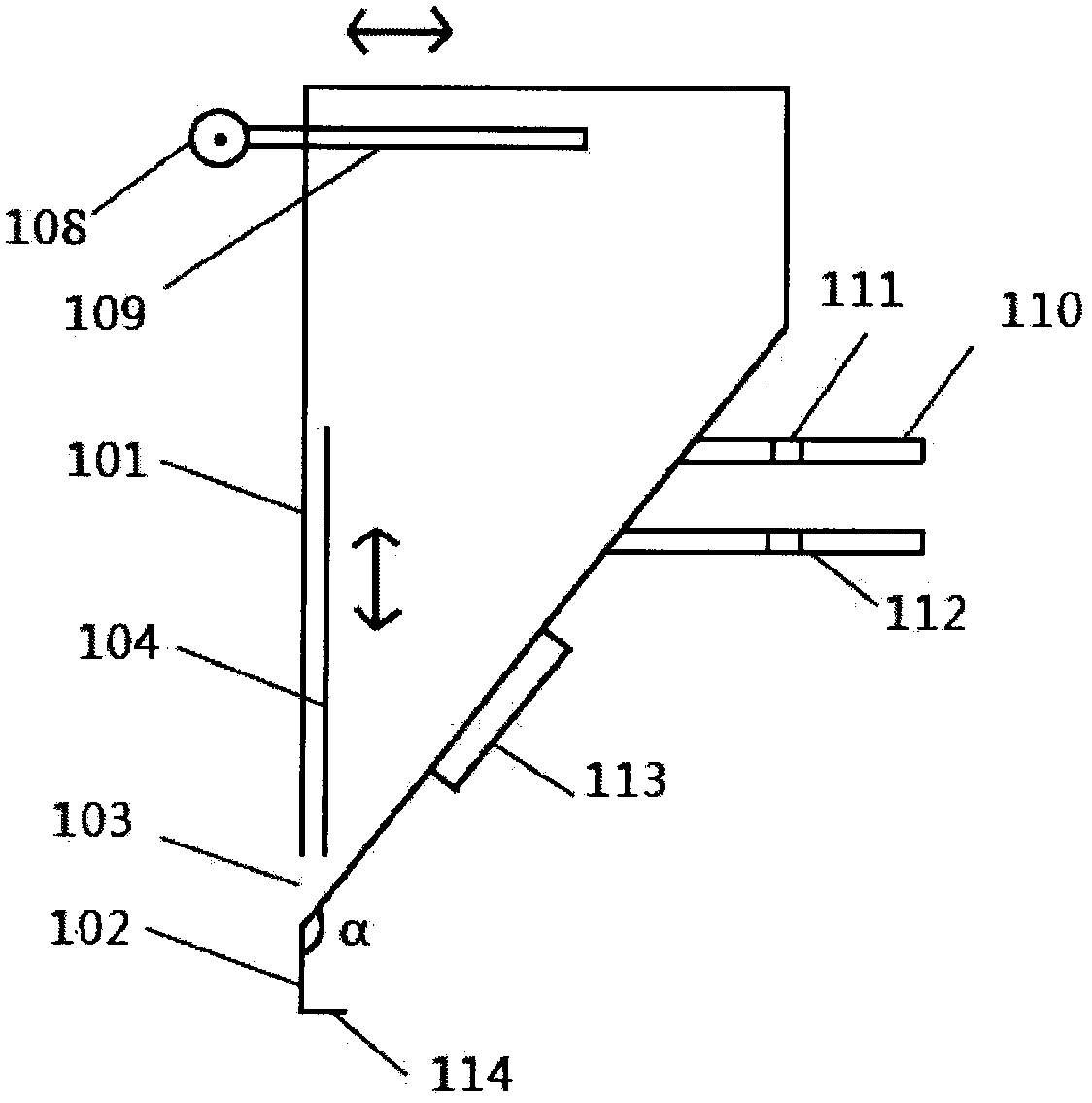

[0029] combined with figure 2 , attached image 3 , attached Figure 4 Further detail with examples: the lower end of the front baffle plate 101 of the hopper is connected to the plastering board 102 provided with the discharge port 103, the bottom surface of the hopper is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com