Marine medium-and-high-speed oil-gas double-electric-control dual-fuel engine

A dual-fuel engine, medium-to-high-speed technology, applied in engine control, machine/engine, electrical control, etc., can solve the problem of failure to meet the emission limit requirements of marine engines, the engine cannot enter the dual-fuel mode state, and the replacement rate of dual-fuel engines is low and other issues, to achieve the effect of improving fuel substitution rate, ensuring safety, and stringent emission limit requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

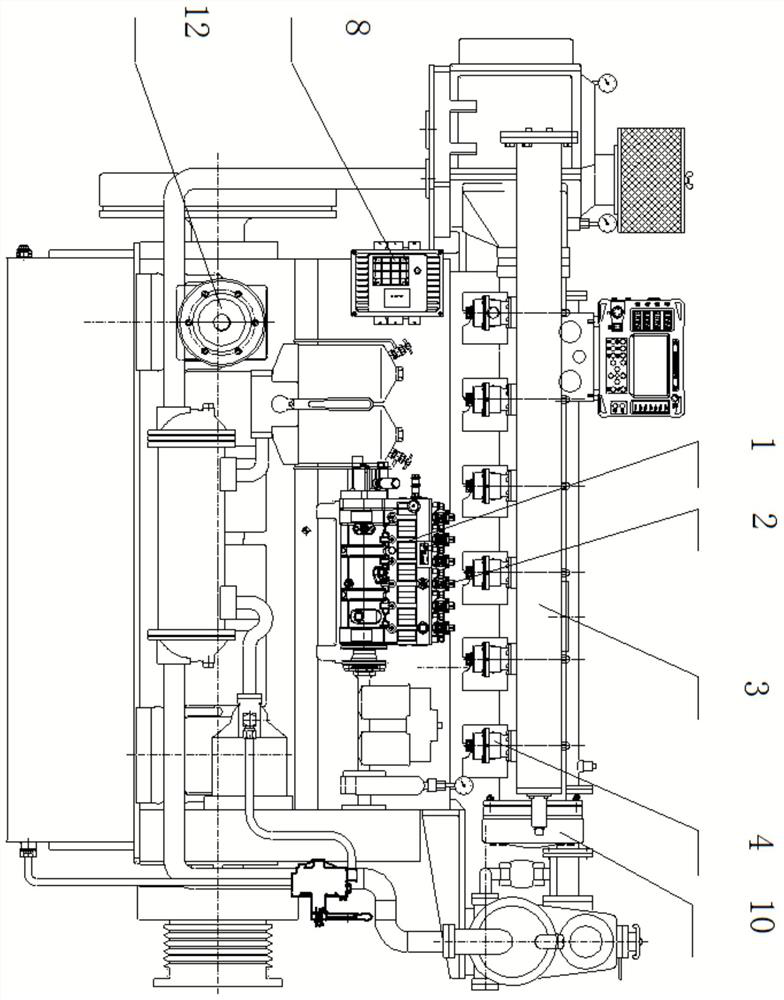

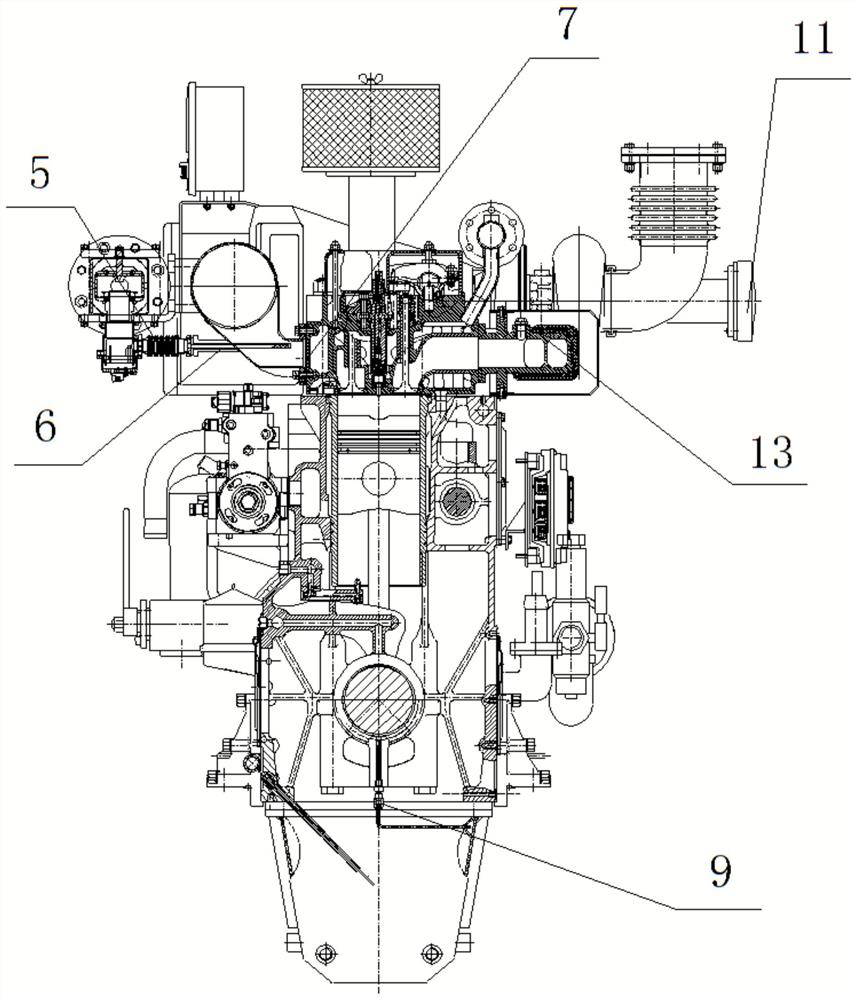

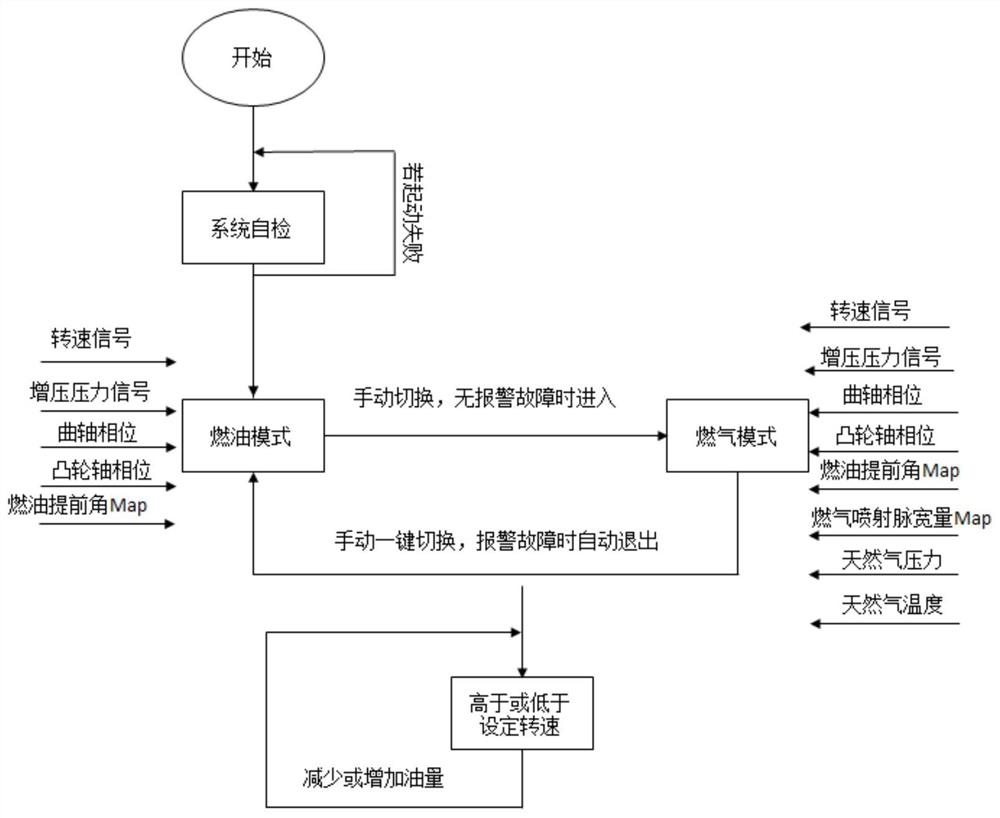

[0034] Such as figure 1 , 2 As shown, the high-pressure fuel injection electric control combination pump 1 is driven by the engine gear chamber through the coupling, and the fuel injection solenoid valve 2 is respectively installed at the oil outlet of the plunger of each cylinder, and its control is through the oil and gas dual control ECU 8. The fuel control part controls the fuel injection timing and fuel quantity; serial number 3 is the common rail pipe of the natural gas injection system, which has a double-wall structure, the inner side is the gas supply rail pipe, and the outer side is the ventilation pipe, and each cylinder is equipped with a gas injection solenoid valve 4. The opening and closing of the gas injection solenoid valve 4 is controlled by the gas part in the oil-gas dual control ECU 8, and the gas is directly injected to the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com