Four-wheel drive rotary cultivator

A rotary tiller and rotary tiller technology, applied in the field of rotary tiller, can solve the problems of the fixed height of the rotary tiller, insufficient climbing ability, and easy falling in, etc., and achieve high manufacturing cost and strong soil crushing ability , the effect of flat surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

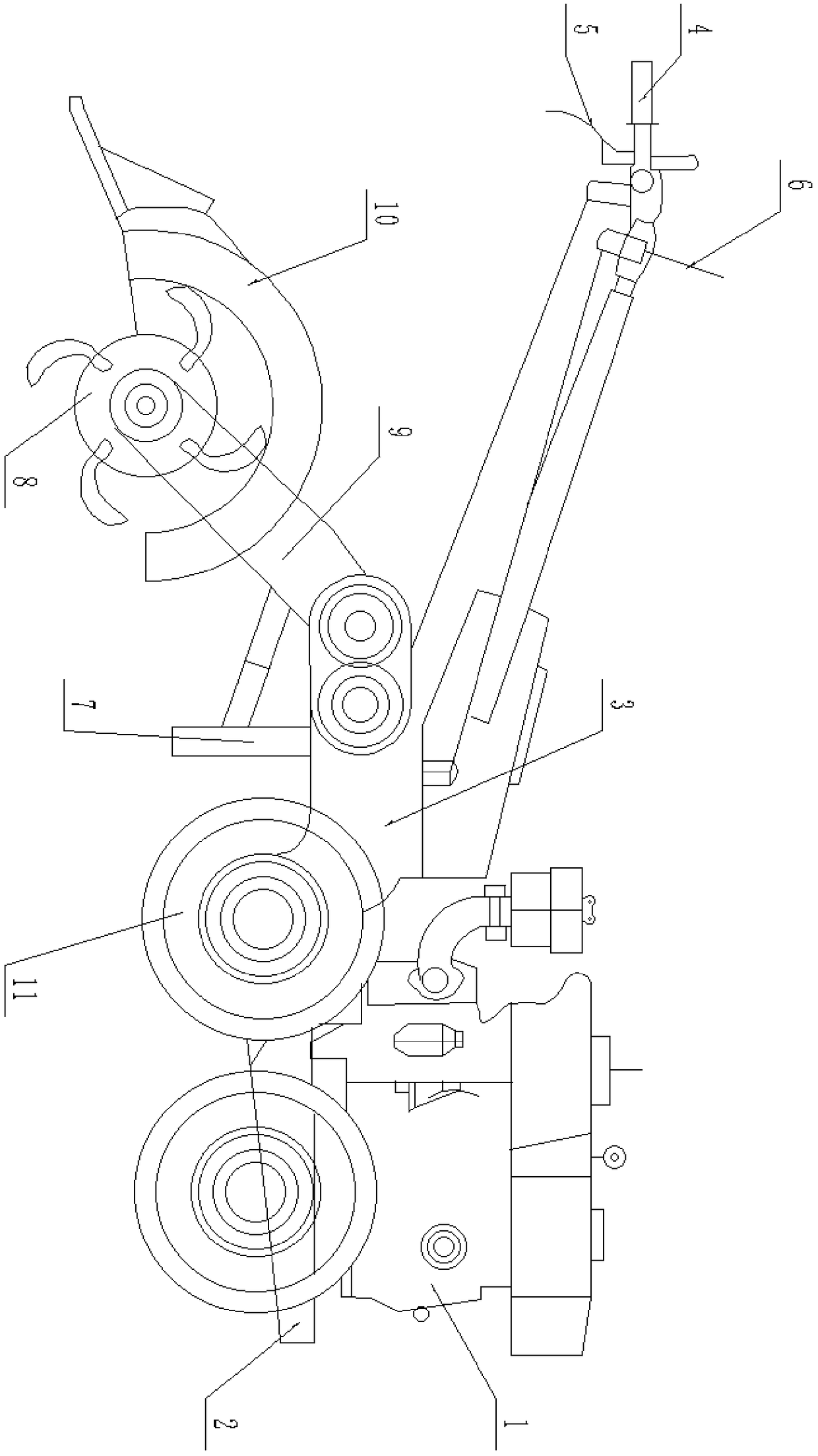

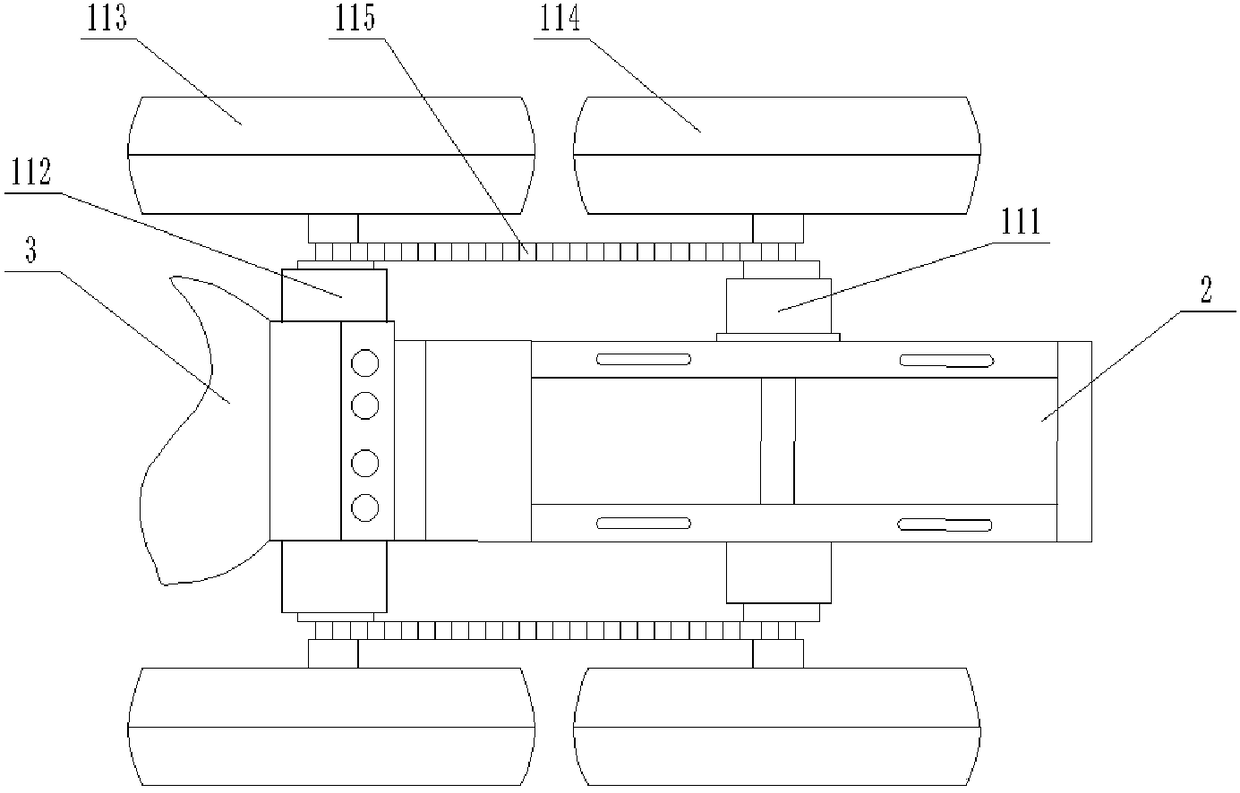

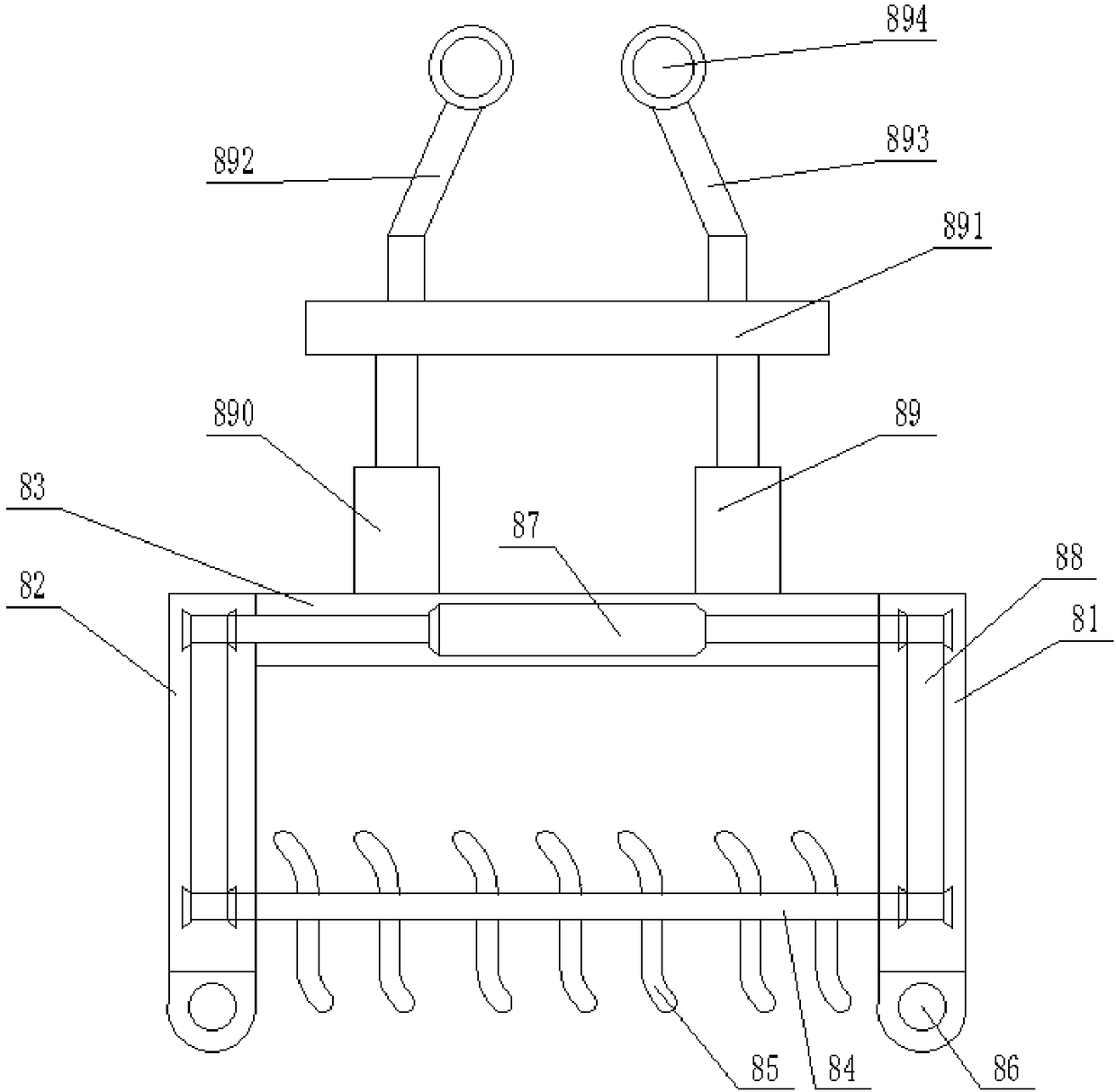

[0024] Such as figure 1 , figure 2 with image 3 As shown, the specific embodiment adopts the following technical solutions: a four-wheel drive rotary cultivator, including: diesel engine 1, diesel frame 2, gearbox 3, operating handle 4, steering handle 5, hydraulic lifting handle 6 and lifting Oil cylinder 7, the diesel engine 1 is fixedly connected to the front end of the diesel frame 2, the gearbox 3 is fixedly connected to the middle end of the diesel frame 2, the output shaft of the diesel engine 1 is connected to the input end of the gearbox 3 through a belt Together, the operating handle 4, the steering handle 5 and the hydraulic lifting handle 6 are arranged on the end of the diesel frame 2, and the operating handle 4 and the steering handle 5 are connected to the control end of the gearbox 3 through steel cables Above, the lifting cylinder 7 is fixedly connected to the lower end of the gearbox 3, and the hydraulic lifting handle 6 is connected to the control end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com