Hydraulic speed reducing device

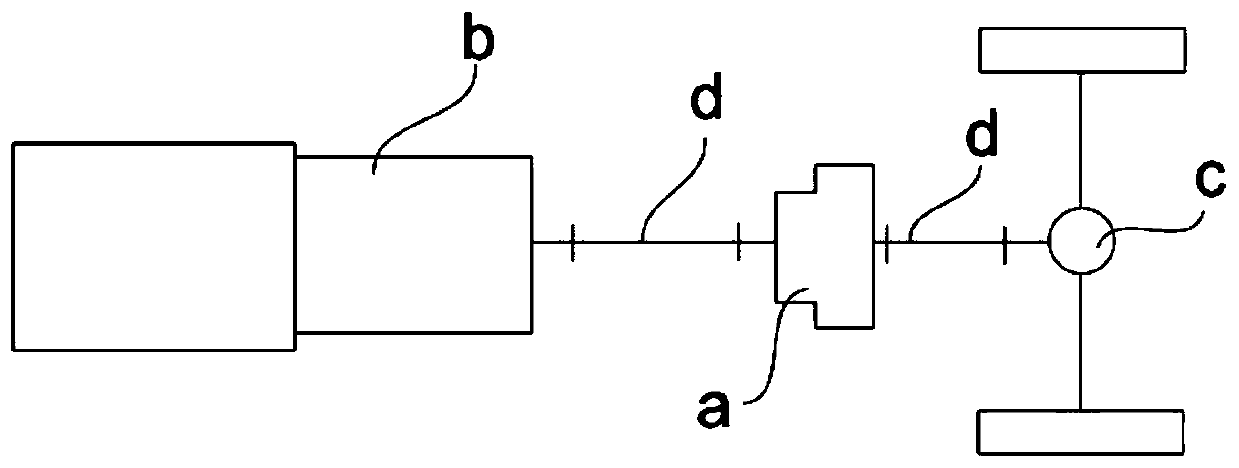

A technology of hydraulic deceleration and rotational speed, applied in the field of hydraulic machinery, can solve the problems of increasing idling loss of hydraulic decelerator, destroying transmission structure, weakening deceleration braking effect of hydraulic decelerator, etc. The effect of changing the braking torque, changing the braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

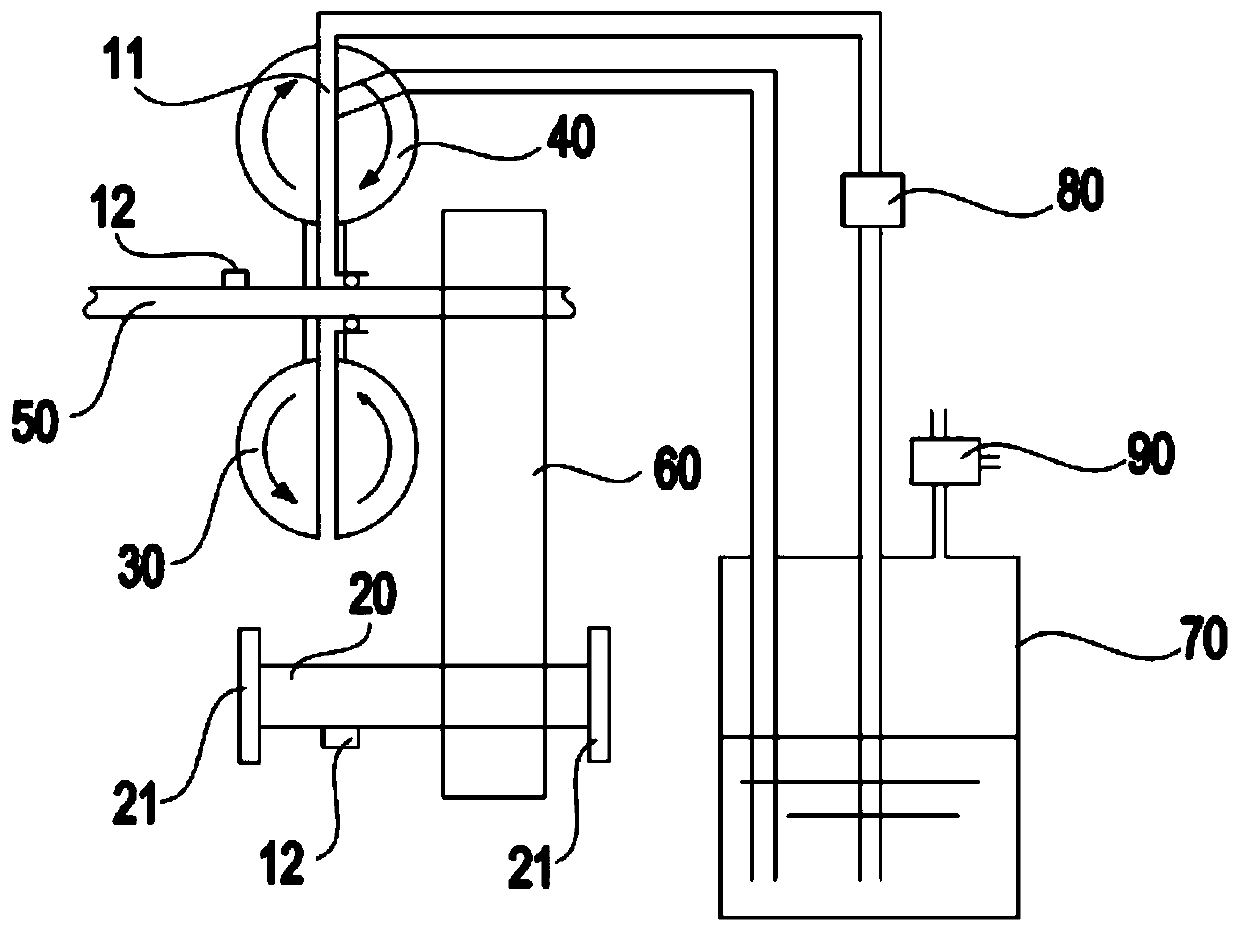

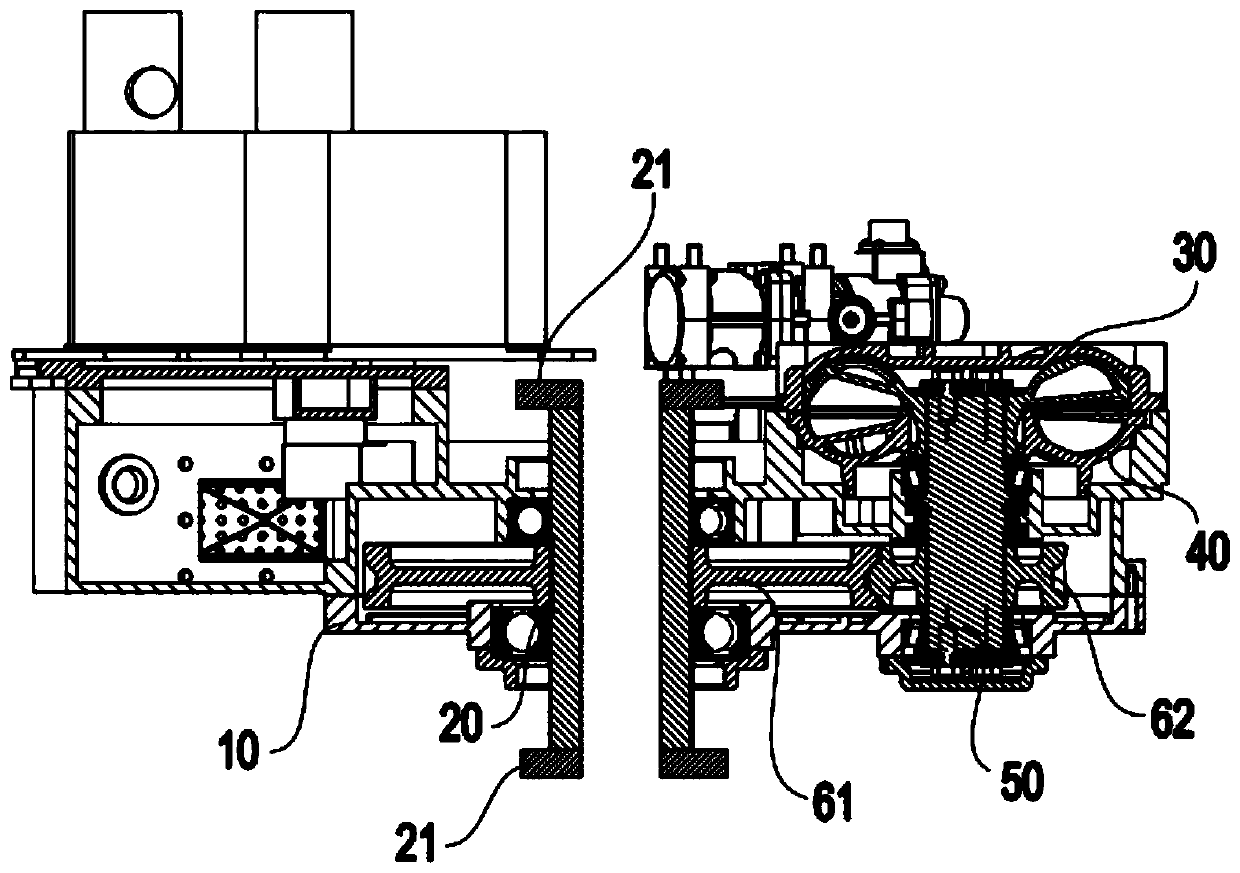

[0035] combine image 3 and Figure 4As shown, the speed regulating mechanism 60 includes a first speed change gear 61 and a second speed change gear 62, wherein the first rotating shaft 20 is pivotally connected to the first speed change gear 61, the second rotating shaft 50 is pivotally connected to the second speed change gear 62, and the first speed change gear 61 is meshed with the second transmission gear 62 . During specific implementation, the first rotating shaft 20 drives the first transmission gear 61 to rotate, and the first transmission gear 61 further drives the second transmission gear 62 meshed with it to rotate; the second transmission gear 62 drives the second rotation shaft 50 to rotate, and then drives the rotor The rotation of the impeller 30 changes the rotational speed of the rotor impeller 30 under the action of the first speed change gear 61 and the second speed change gear 62 , thereby changing the braking torque of the hydraulic speed reduction devi...

Embodiment 2

[0038] like Figure 5 As shown, the speed regulating mechanism 60 includes a first speed change gear 61, a second speed change gear 62, a third speed change gear, a fourth speed change gear and a third shaft, wherein the third shaft is connected to the third speed change gear and the fourth speed change gear , the first shaft 20 is connected to the first speed change gear 61, and the first speed change gear 61 is meshed with the third speed change gear, the second shaft 50 is connected to the second speed change gear 62, and the second speed change gear 62 is connected to the fourth speed change gear Gear mesh connection.

[0039] During specific implementation, the first rotating shaft 20 drives the first transmission gear 61 to rotate, and the first transmission gear 61 further drives the third transmission gear 63 meshed with it to rotate; the second transmission gear 62 drives the third rotation shaft 65 to rotate, and then drives the third transmission gear 63 to rotate. ...

Embodiment 3

[0042] like Image 6 As shown, the speed regulating mechanism 60 includes a first speed change gear 61, a second speed change gear 62, a third speed change gear, a fourth speed change gear and a clutch, wherein the first rotating shaft 20 is pivotally connected to the first speed change gear 61 and the third speed change gear , the second rotating shaft 50 is pivotally connected to the second speed change gear 62 and the fourth speed change gear, and the first speed change gear 61 is meshed with the second speed change gear 62, and the third speed change gear is meshed with the fourth speed change gear; further, The clutch is arranged on the second rotating shaft 50 and is positioned between the second speed change gear 62 and the fourth speed change gear, and it can be combined with any one in the second speed change gear 62 and the fourth speed change gear 64, and can also be combined with the second speed change gear 62 and the fourth speed change gear 64. Both the speed ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com