Fly ash melting system based on pure oxygen combustion and used for waste incineration plant

A technology of waste incineration and fly ash, which is applied in combustion methods, combustion types, incinerators, etc., can solve the problems of inability to eliminate pollutants, limited application scope, and no reasonable utilization, and achieve simultaneous resource disposal, Good effect, fully processed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

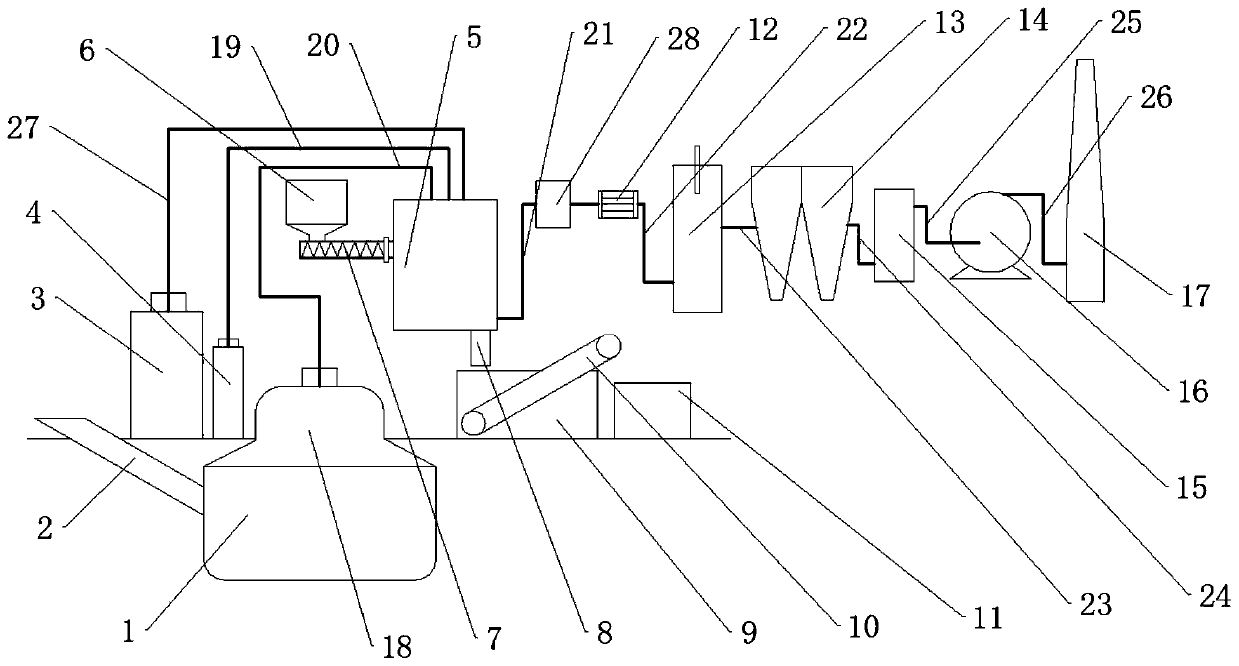

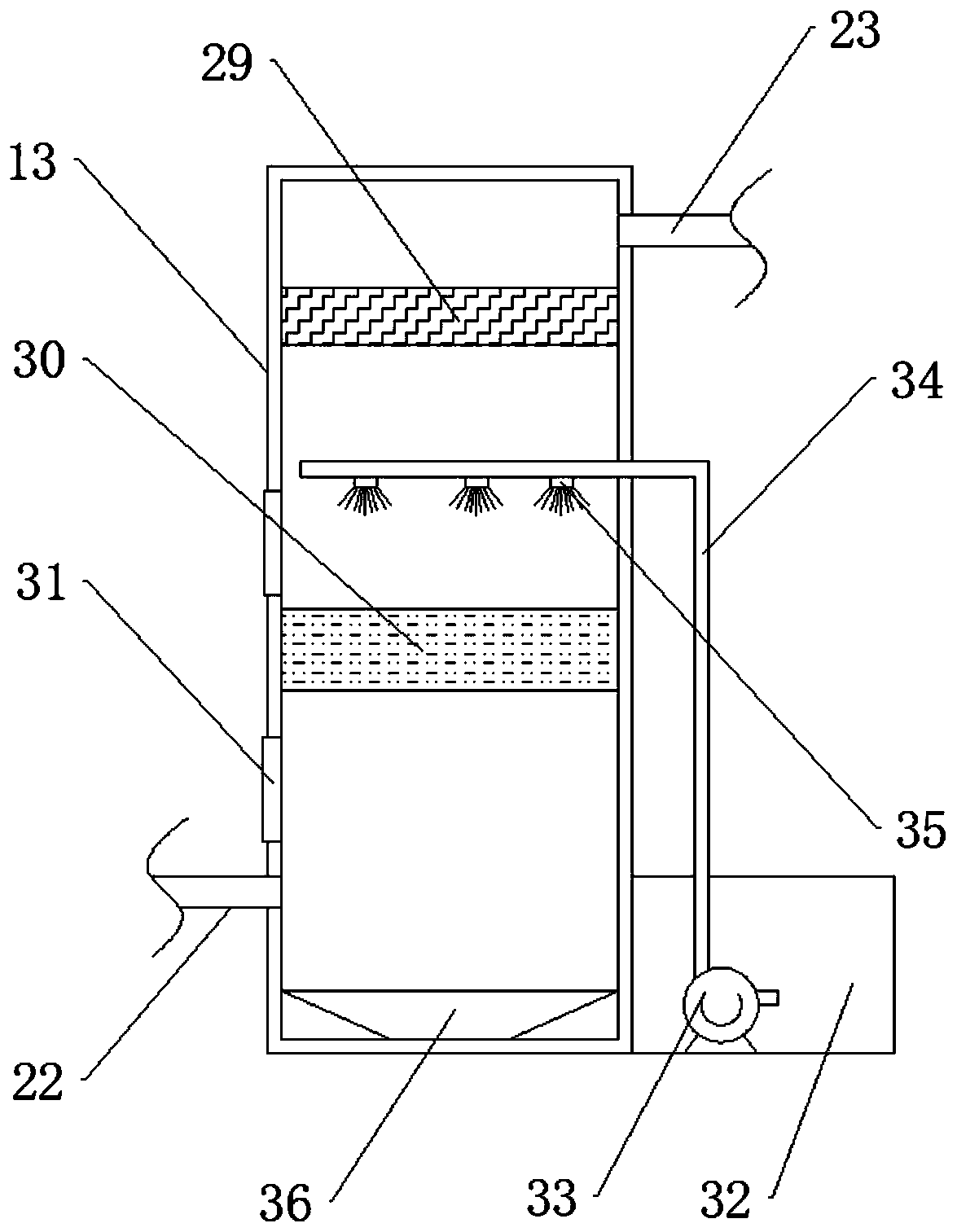

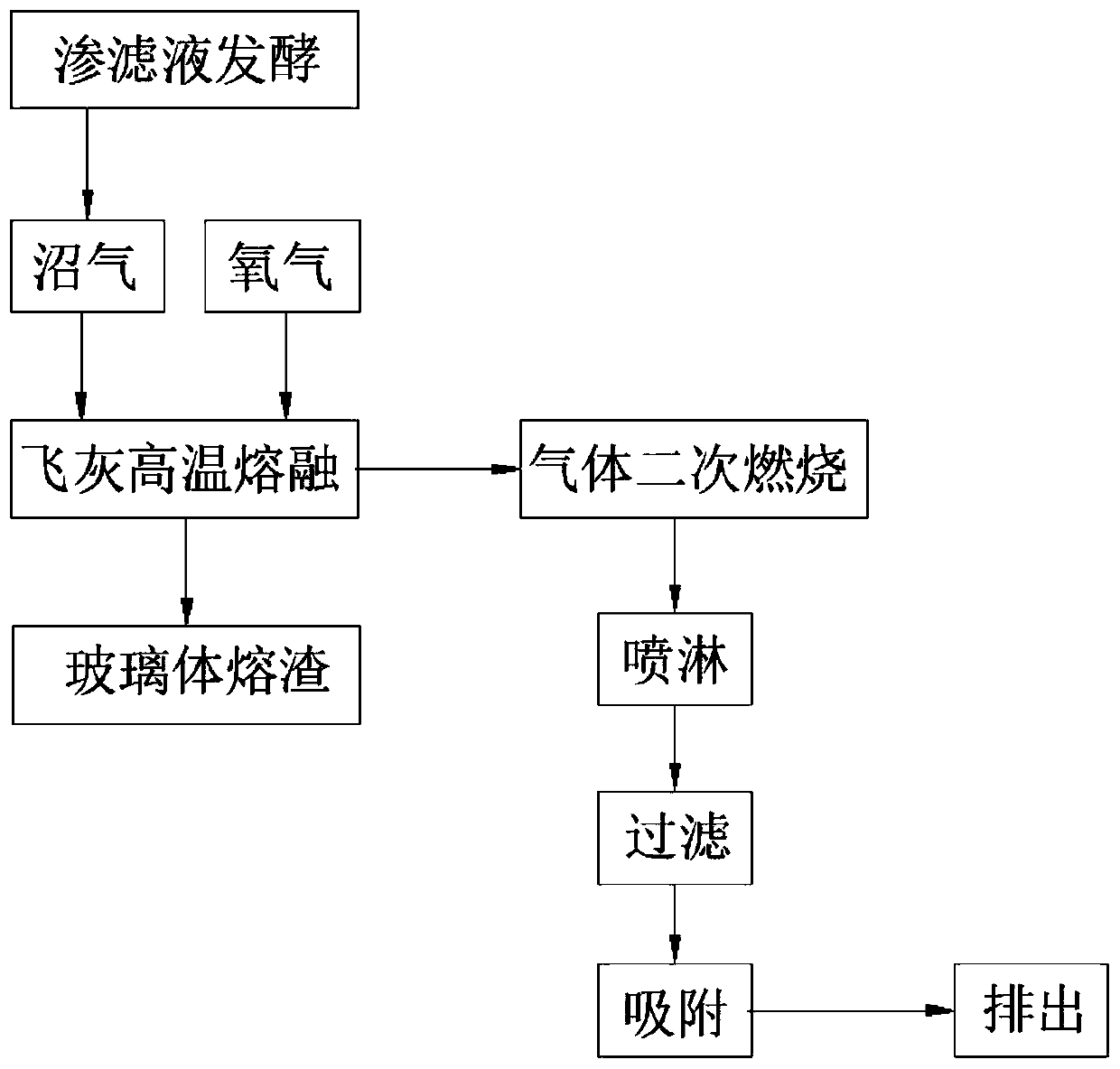

[0042] see figure 1 , a fly ash melting system for waste incineration plants based on pure oxygen combustion, including a biogas digester 1, a liquid oxygen tank 3, a fly ash melting furnace 5, a heat exchanger 12, an alkali spray tower 13, a dust collector 14, an adsorption Tower 15, fan 16 and chimney 17, dust collector 14 is a bag filter, adsorption tower 15 is an activated carbon adsorption tower, which has good dust removal and adsorption effect and high cost performance. Start and fast braking, no spark, explosion-proof, strong environmental adaptability, the feed port 2 is connected to the biogas digester 1, through which the leachate produced by the waste incineration plant or other materials that can generate biogas can be passed through the feed port 2 Enter the biogas tank 1 for fermentation, the upper end of the biogas tank 1 is connected with a gas storage tank 18, and the biogas tank 1 is connected with the gas storage tank 18, the biogas produced by fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com