A Unipolar Magnet Rotary Adjustable Speed Cage Magnetic Coupler

A magnetic coupling and rotary technology, applied in the field of mechanical transmission, can solve the problems of large eddy current loss, failure to meet speed regulation requirements, small speed regulation range, etc., achieve small eddy current loss, increase service life, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

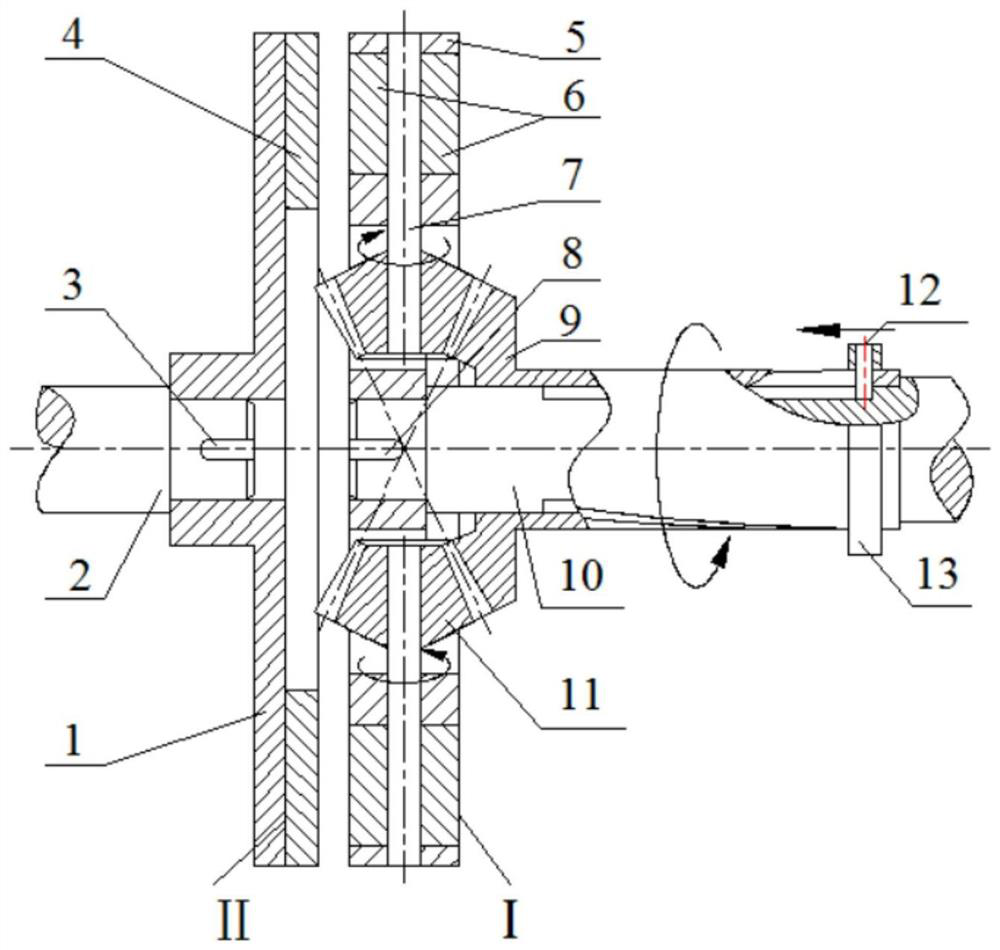

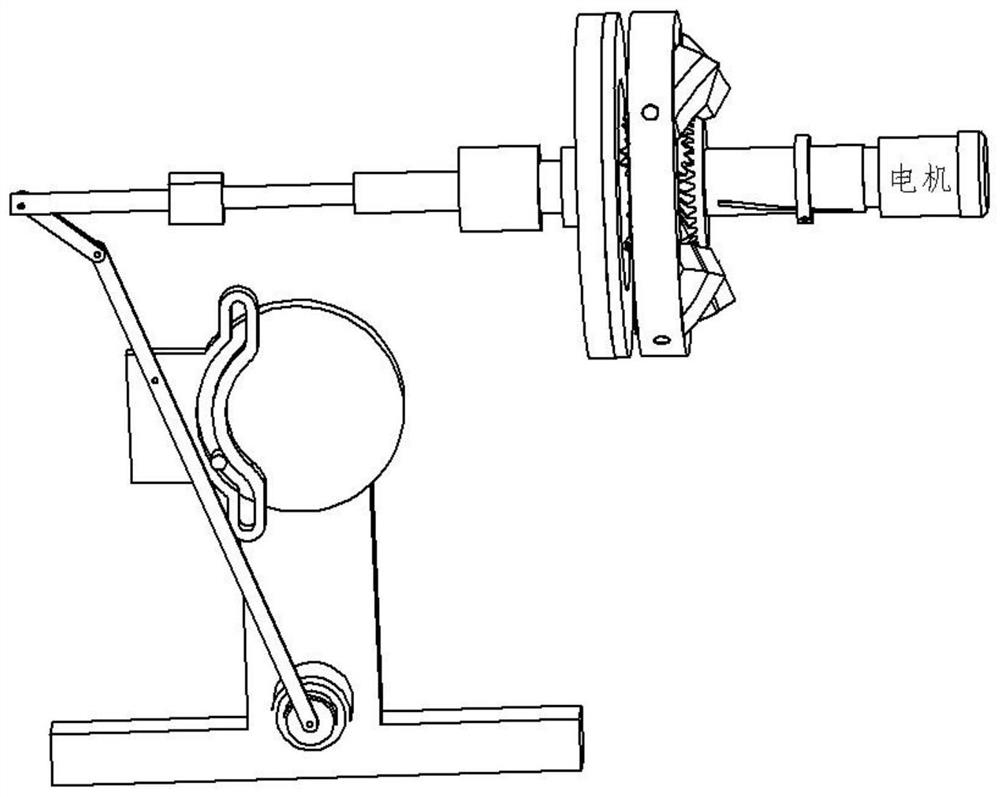

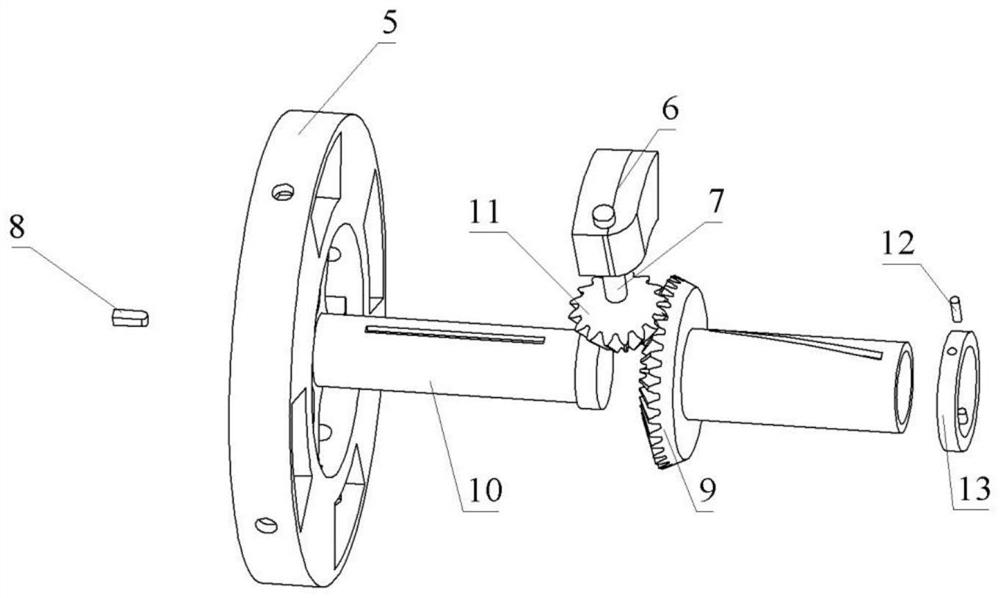

[0030] figure 1 Among them, the device is composed of driving disk assembly I and driven disk assembly II, and the speed regulating device is arranged on driving disk assembly I. figure 1 and figure 2 Among them, the driving disc assembly 1 includes a driving disc 5, an annular shifting block 13, a shifting block pin 12, a driving shaft 10, a large bevel gear sleeve 9, a small bevel gear 11, a pinion shaft 7 and a permanent magnet assembly 6 , the outer surface of the driving shaft 10 is covered with a large gear sleeve 9, and the right end is covered with an annular shifting block 13, Figure 4 Among them, the surface of the ring shifting block 13 is processed with symmetrically distributed circular radial through holes, image 3 Among them, the surface of the drive shaft 10 and the large bevel gear sleeve 9 are respectively symmetrically processed with straight grooves and oblique grooves, and the shift pin 12 is symmetrically inserted in the radial circular through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com