Composite supersonic motor with great moment and longitudinal torque

An ultrasonic motor and composite technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve problems such as difficulty in low speed and large torque, and achieve high positioning accuracy, The effect of weight reduction and rapid energy decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

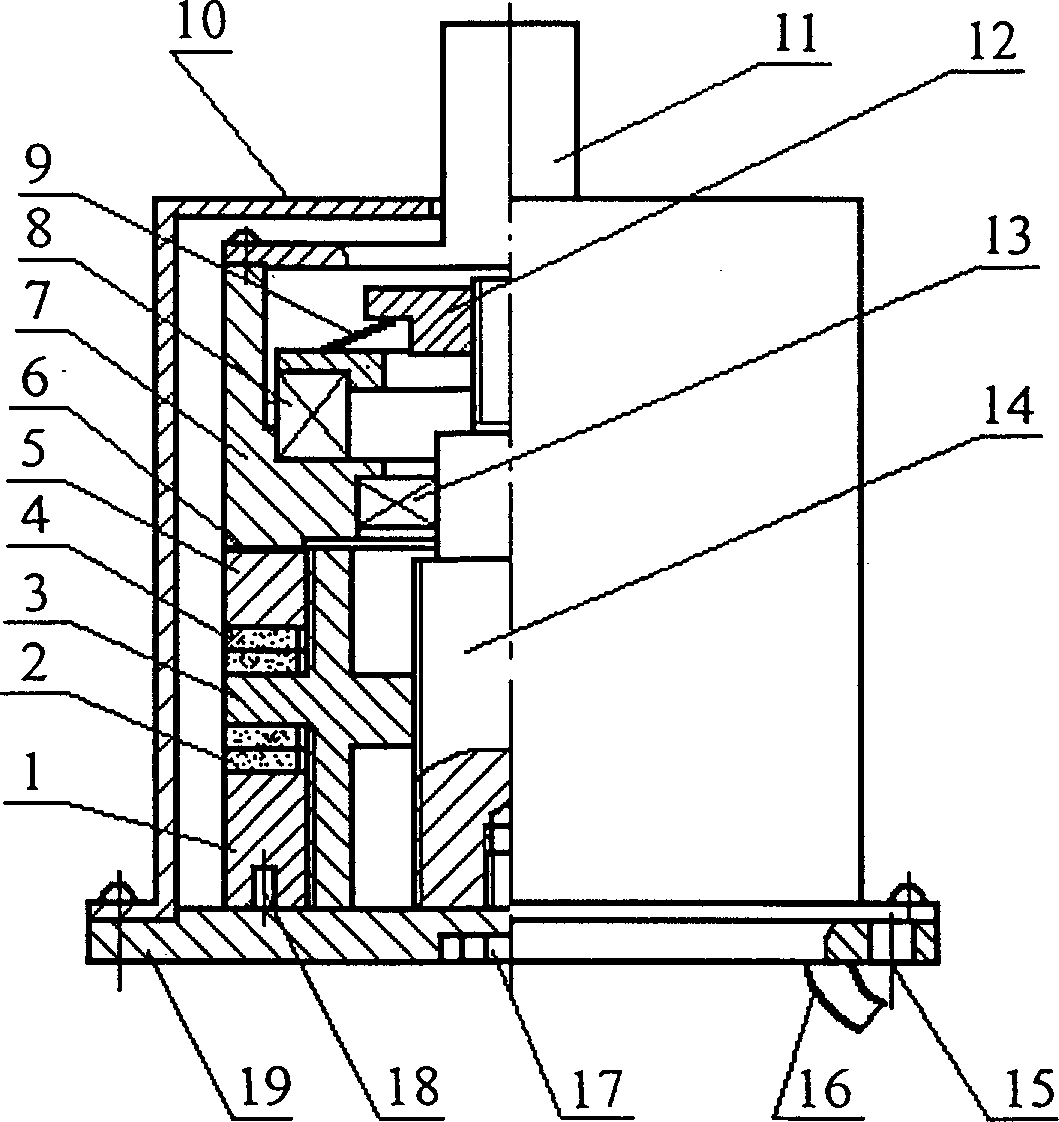

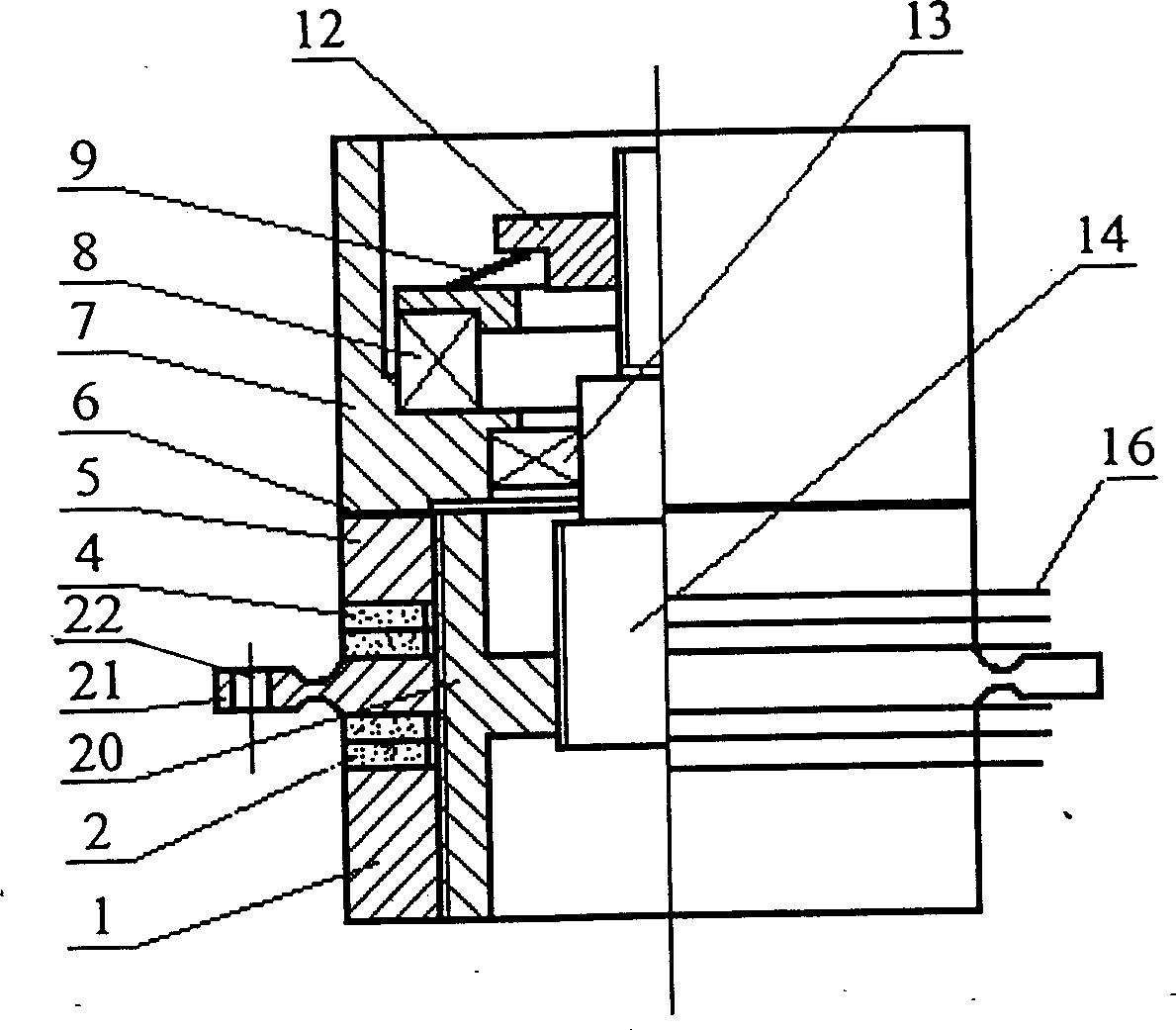

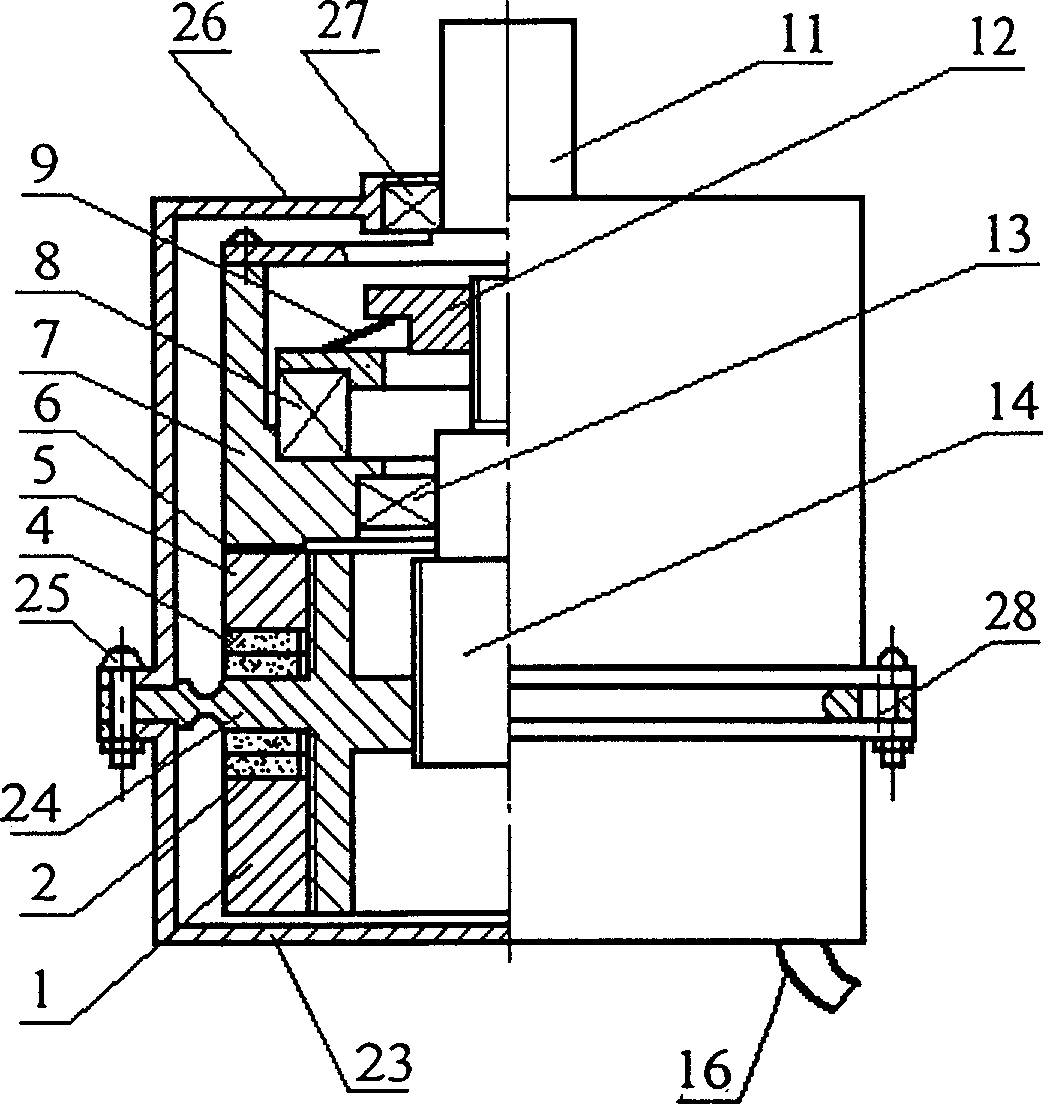

[0020] Such as figure 1 As shown, it includes a stator composed of a lower metal ring 1, a piezoelectric ceramic torsional vibrator 2, an intermediate metal body 3, a piezoelectric ceramic longitudinal vibrator 4, and an upper metal ring 5, a rotor 7, and a mandrel 14; On the shoulder, from bottom to top, there are inherent piezoelectric ceramic longitudinal oscillators 4, upper metal ring 5, and under the shoulder of the intermediate metal body 3, from top to bottom, inherent piezoelectric ceramic torsional oscillators 2, lower metal ring 1, and the intermediate metal body 3 is fixed on the mandrel 14, the bottom surface of the mandrel 14 and the lower metal ring 1 are fixed on the bottom plate 19, the outer surface of the bottom of the rotor 7 is bonded with the friction material 6, and the radial bearing 13 is installed on the mandrel 14 above the stator, through Axial thrust bearing 8, belleville spring 9 use compression nut 12 to compress stator and rotor, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com