Motor control circuit for laser swinger

A laser leveling instrument and motor control technology, applied in the direction of excitation or armature current control, etc., can solve the problems of large power supply ripple, excessive time delay, and difficulty in speed adjustment, and achieve stable speed in a short time and consume less resources. , The effect of convenient speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

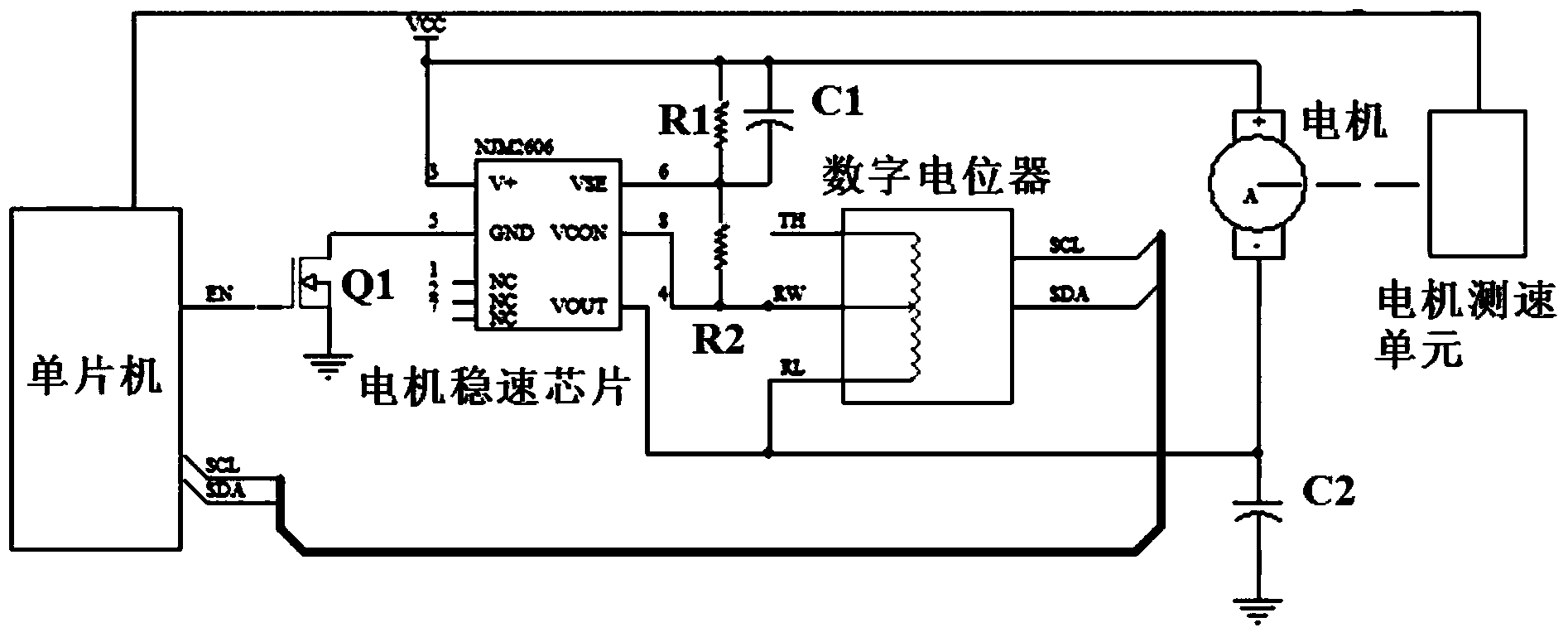

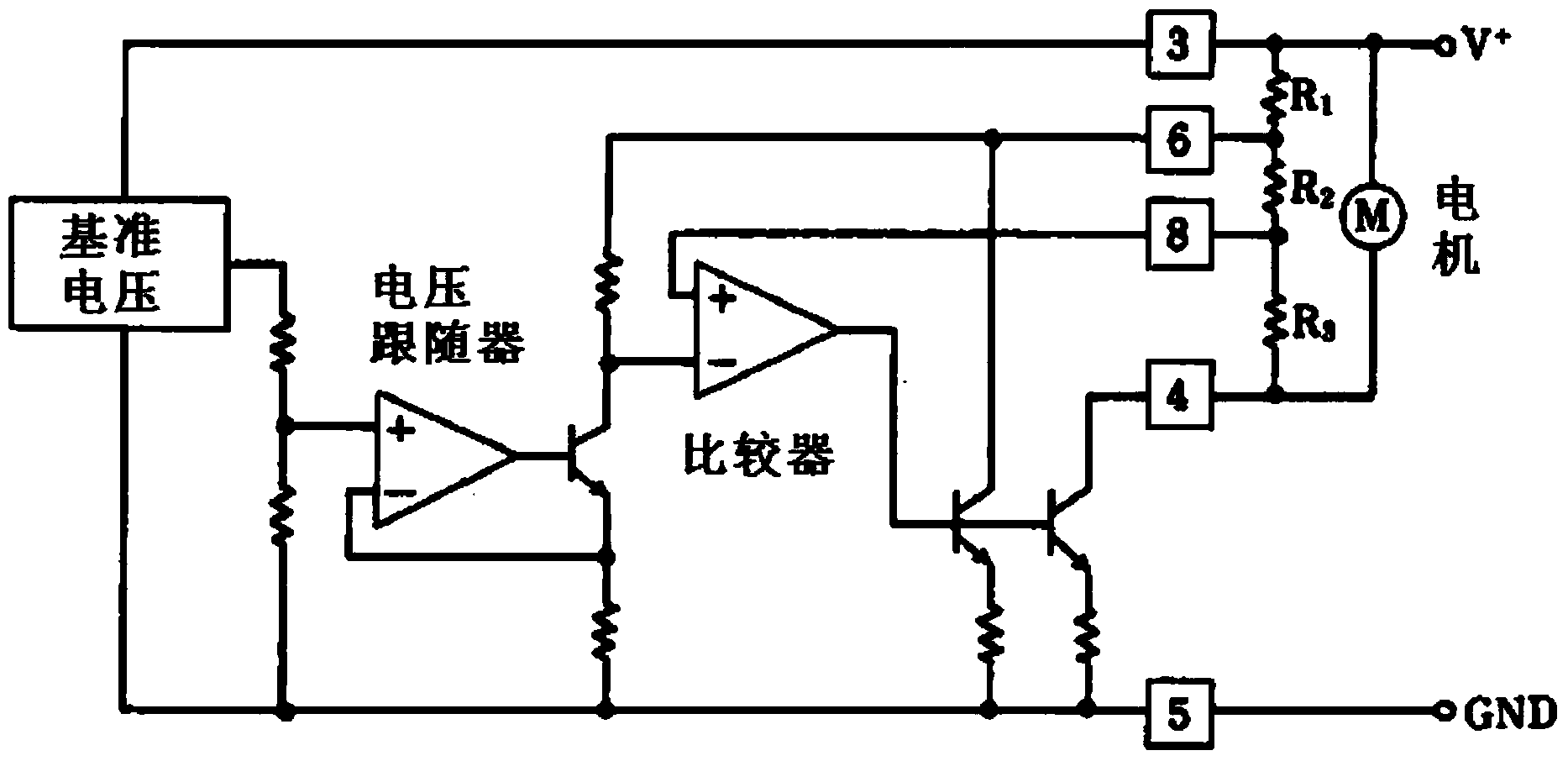

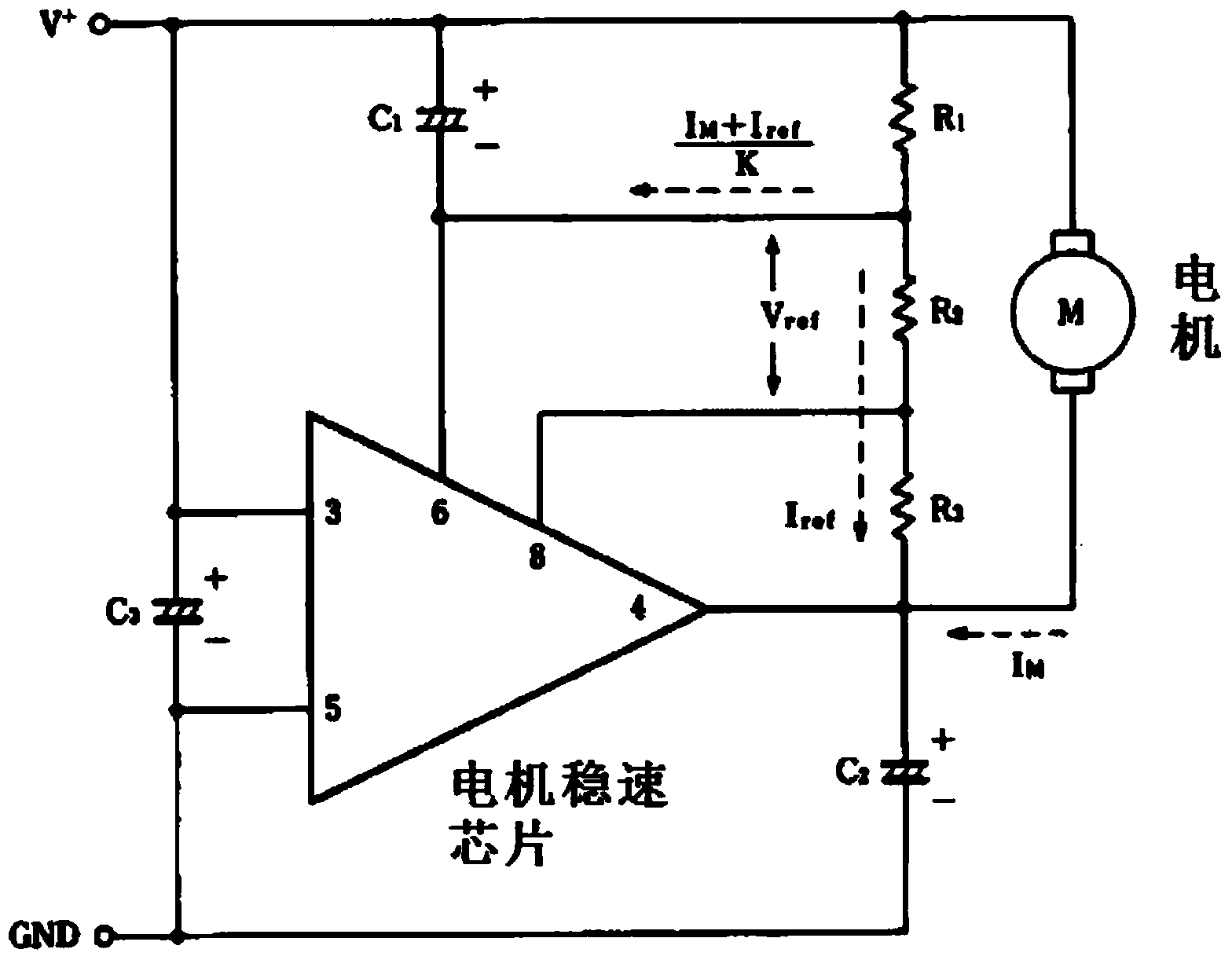

[0028] refer to figure 1 , is a schematic circuit diagram of the motor control circuit in a preferred embodiment of the present invention. In the present invention, the motor control circuit is connected to both ends of the motor of the laser leveling instrument to control the speed of the motor. The motor control circuit includes a motor speed stabilization module and a motor speed regulation module. The motor speed stabilization module adopts the configuration of a single-chip microcomputer and a motor speed stabilization chip. The motor speed stabilization chip is connected to both ends of the motor, using its own properties and functions , to stabilize and adjust the motor speed at a constant speed. The single-chip microcomputer is connected with the motor speed stabilizing chip, and controls the working state of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com