Three-speed planetary gear automatic transmission and pure electric vehicle

An automatic transmission and planetary gear technology, applied in the field of vehicle transmission system, can solve the problems of unstable transmission, large structure occupied space, single transmission ratio, etc., and achieve the effect of simple and compact structure, space saving and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

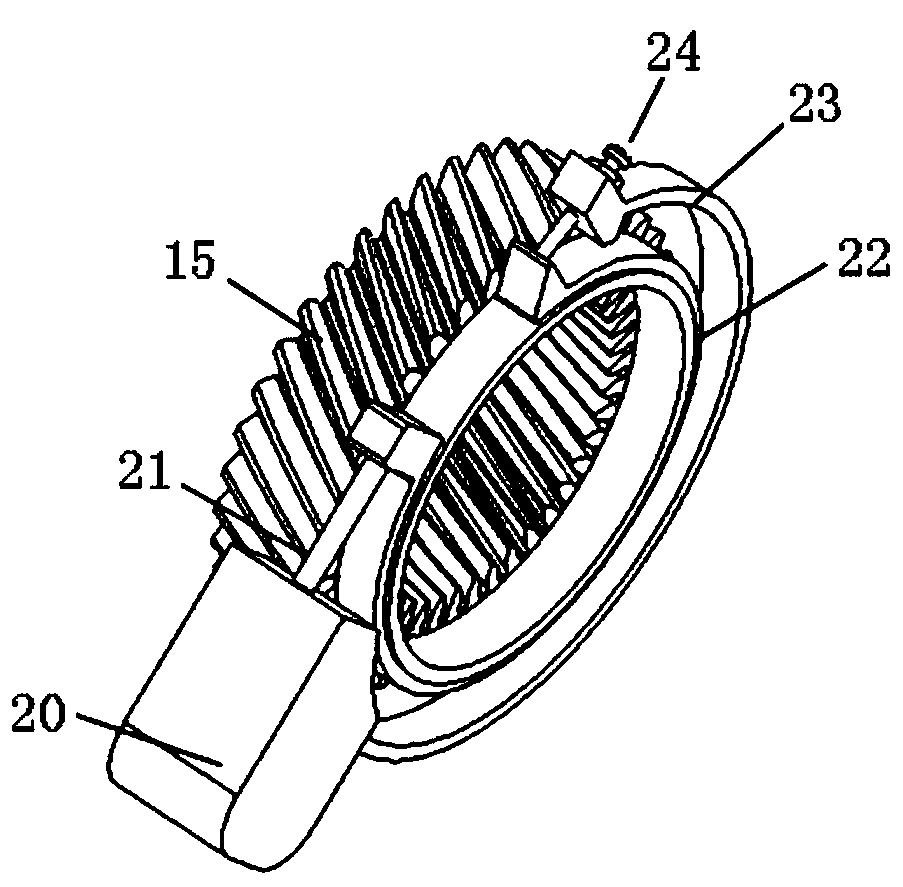

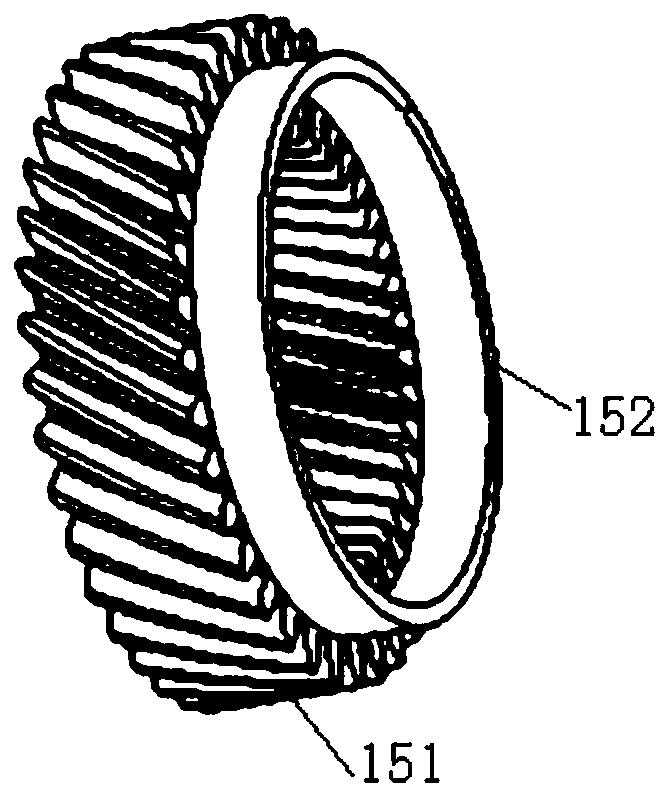

[0057] Please also refer to figure 2 and image 3 , as a specific embodiment of the three-speed planetary gear automatic transmission provided by the present invention, the planetary ring gear 15 has a gear part and a brake part, the first brake B1 is installed on the brake part, and the first brake B1 includes a brake Band 22, brake housing 23, brake motor 20 and motor push rod 21, brake band 22 and brake housing 23 all have openings, brake motor 20 is installed on one end of brake housing 23, and the push rod of brake motor 20 The rod is connected with one end of the brake band 22, and the other end of the brake housing 23 is connected with the other end of the brake band 22 by means of an adjustment screw. The adjustment screw is provided with an adjustment nut, and the brake motor 20 pushes the motor push rod 21 to compress the system. The moving belt 22 brakes the planetary ring gear 15 . The combination relationship between the planetary ring gear 15 and the first bra...

Embodiment approach

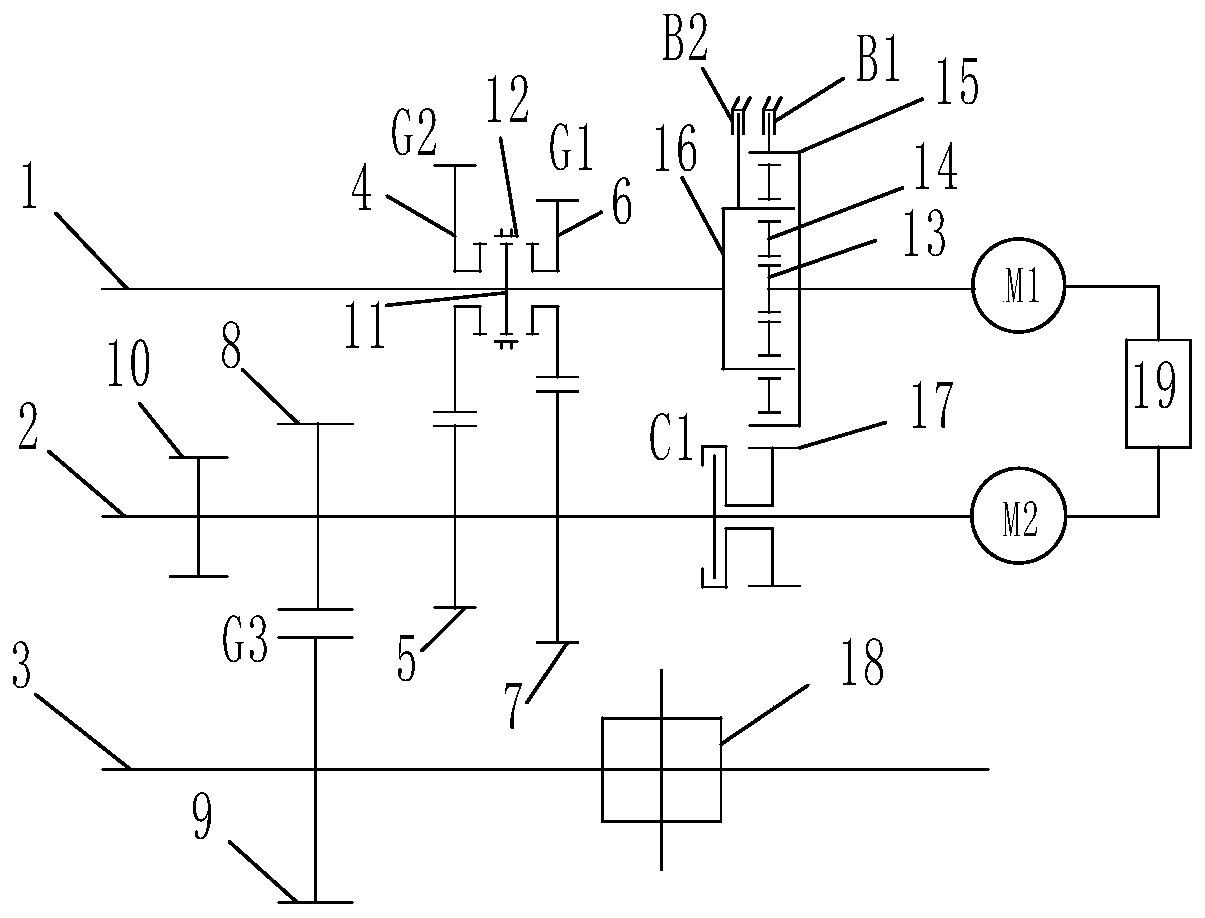

[0069] see figure 1 , as a specific implementation of the three-speed planetary gear automatic transmission provided by the present invention, the planetary gear train is arranged close to the main driving motor M1, the second gear driving gear 4 is far away from the driving main motor M1, and the first gear driving gear 6 is in the second gear Between the driving gear 4 and the planetary gear train.

[0070] refer to figure 1 , as a specific embodiment of the three-speed planetary gear automatic transmission provided by the present invention, when the first and second gears are shifted, the auxiliary motor M2 intervenes to work and directly drives the output shaft to rotate, so that the power is continuous when shifting gears.

[0071] Another object of the present invention is to provide a pure electric vehicle equipped with the three-speed planetary automatic transmission. The pure electric vehicle has the advantages of simplicity and compactness, stable transmission, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com