Transmission, driving system and vehicle

A drive system and transmission technology, applied in the field of transmission, can solve problems such as complex shifting process, difficulty in increasing gears, difficulty in starting clutch development, etc., to achieve the effect of realizing the number of gears, avoiding the difficulty of development, and ensuring the quality of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

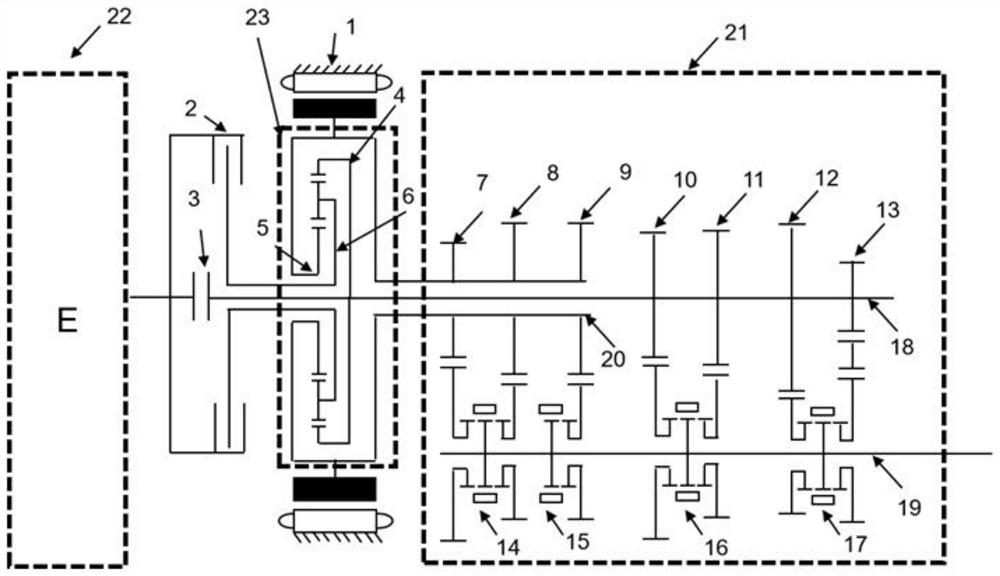

Embodiment 1

[0049] A transmission, including a planetary gear train, a first clutch, a second clutch and a gearbox;

[0050] The gearbox includes a first input shaft and a second input shaft;

[0051] The first clutch is in transmission connection with the first input shaft;

[0052] The planetary gear train is respectively connected in drive with the second clutch and the second input shaft.

[0053] The gear box also includes an output shaft, a plurality of transmission gear pairs, and a synchronous piece matched with the transmission gear pairs; the gear box is a double-shaft gearbox;

[0054] A plurality of transmission gear pairs are respectively arranged on the first input shaft and the second input shaft, and the synchronous element is arranged on the output shaft.

[0055] There are seven transmission gear pairs including the first gear pair, the second gear pair, the third gear pair, the fourth gear pair, the fifth gear pair, the sixth gear pair and the seventh gear pair;

[0...

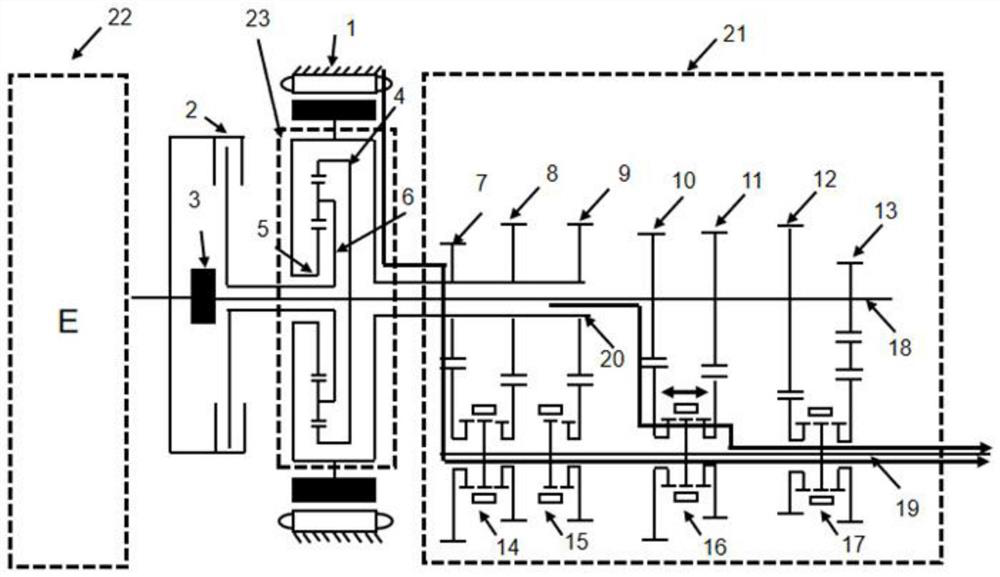

Embodiment 2

[0067] A speed changer, the same parts as Embodiment 1 will not be described in detail, wherein

[0068] The second clutch is in transmission connection with the sun gear.

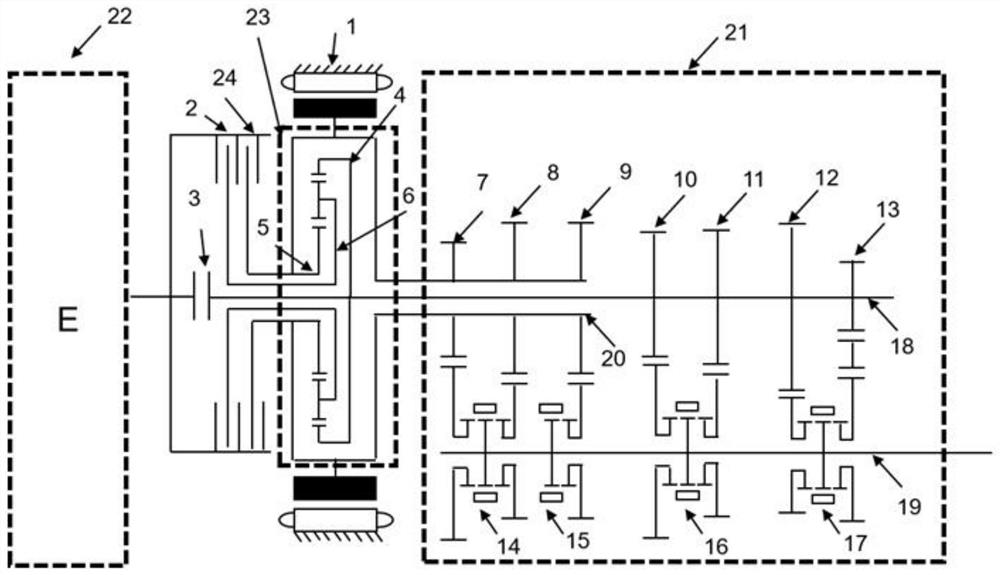

Embodiment 3

[0070] A speed changer, the same parts as Embodiment 1 or Embodiment 2 will not be repeated, wherein

[0071] The transmission also includes a third clutch, which is in transmission connection with the planetary gear train.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com