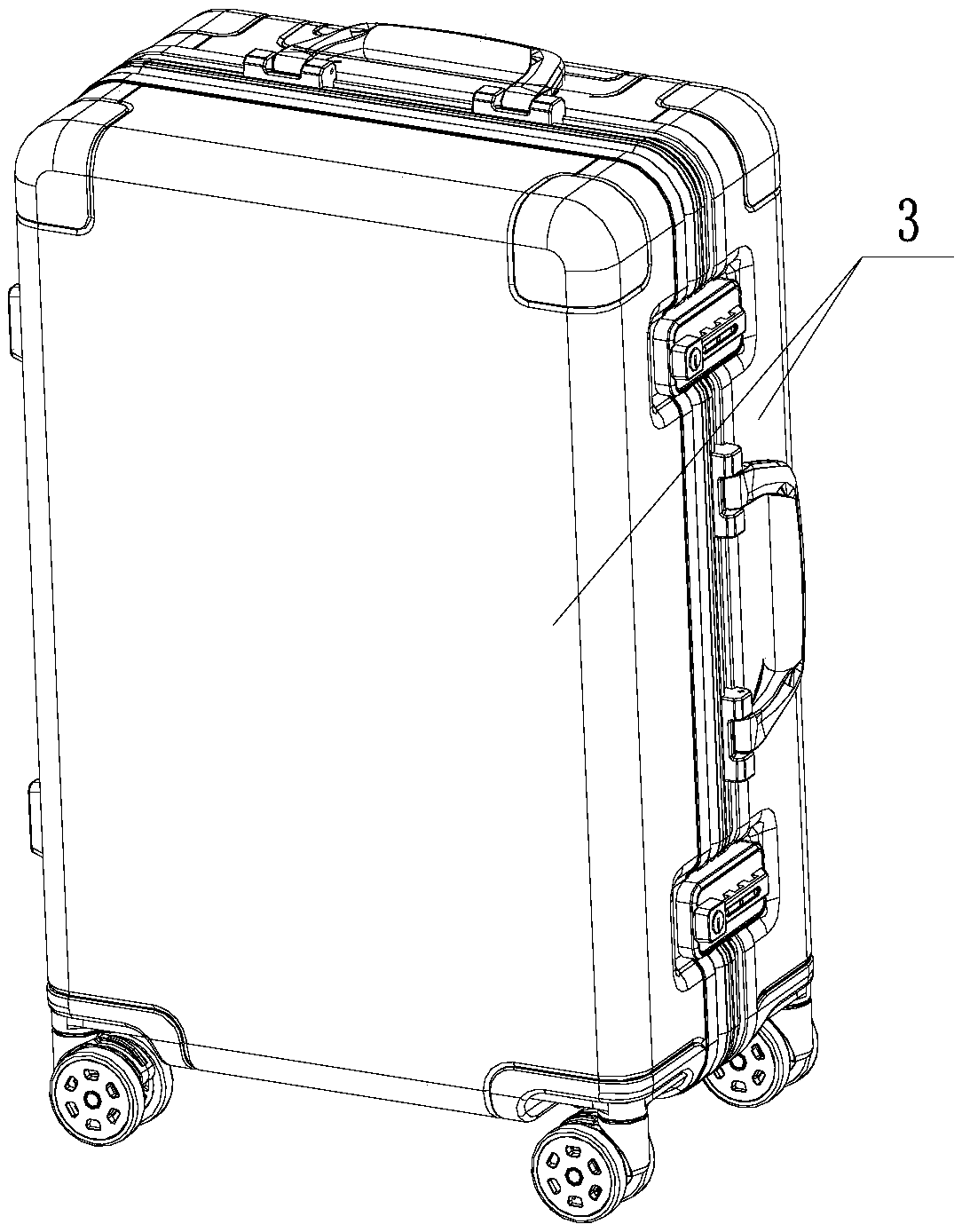

Case shell processing method and assembled case shell for rigid luggage

A processing method and assembled technology, applied in the field of luggage, can solve problems such as high development costs, difficult molding control, and limited market competitiveness, so as to reduce R&D and production costs, improve R&D and production efficiency, and improve market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

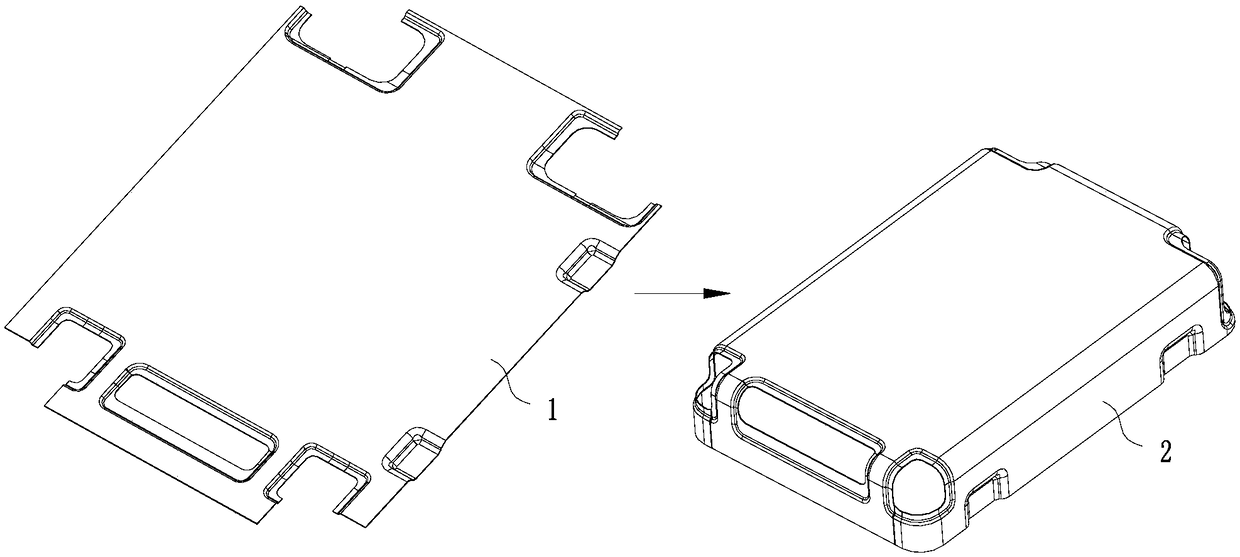

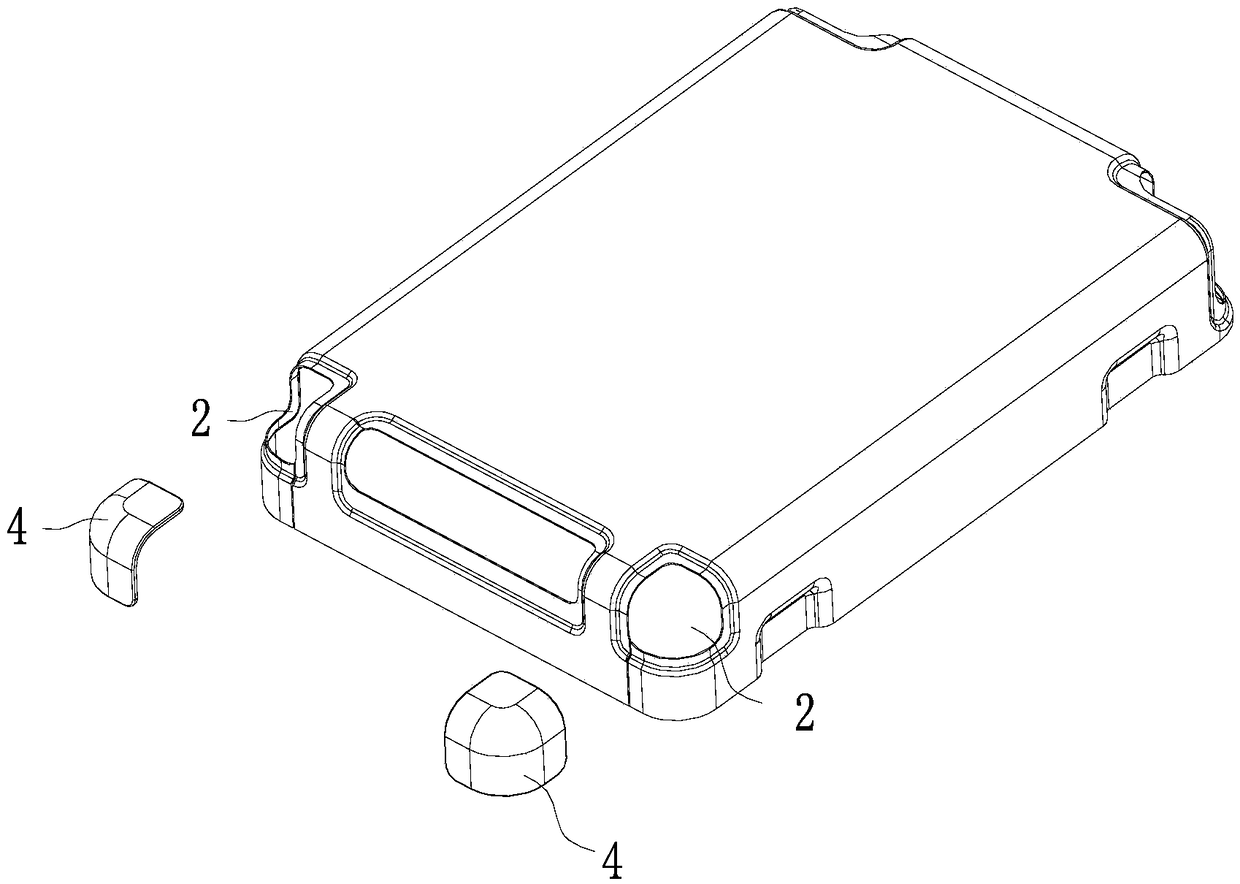

[0042] In this embodiment, a case shell processing method for rigid luggage is firstly divided into a side shell and a middle shell, the middle shell is formed by a stamping and bending process, and the side shell is formed by a deep drawing process, and then The side shell and the middle shell are assembled to form an integral box shell. Such as Figure 7-9 As shown, it specifically includes the following steps:

[0043] (1) Disassemble the box shell into a first side part 6, a middle part shell 7 and a second side part 8 along its length direction;

[0044] (2) The first side part and the second side part form the side part shell, and the one-piece plate is selected, and the blank 5 is formed by drawing process, and then the first side part and the second side part separated from each other are formed by punching department;

[0045] (3) Select the sheet material 9 for forming the middle shell, first punch and form each concave-convex pattern and / or through hole on the mi...

Embodiment 2

[0053] In this embodiment, a case shell processing method for rigid luggage is firstly divided into a side shell and a middle shell, the middle shell is formed by a stamping and bending process, and the side shell is formed by a deep drawing process, and then The side shell and the middle shell are assembled to form an integral box shell. Such as Figure 11-13 As shown, it specifically includes the following steps:

[0054] (1) Disassemble the box shell into the first side part 6, the middle part shell 7 and the second side part 8 along its width direction;

[0055] (2) The first side part and the second side part form the side part shell, and the one-piece plate is selected, and the blank 5 is formed by drawing process, and then the first side part and the second side part separated from each other are formed by punching department;

[0056] (3) Select the sheet material 9 for forming the middle shell, first punch and form each concave-convex pattern and / or through hole on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com