Device and method for double-machine serial twisting of large cross-section concentric conductors of submarine cables

A submarine cable and large cross-section technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high input cost, low operating speed, and low efficiency, so as to avoid development and manufacturing difficulties and save investment costs , The effect of high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

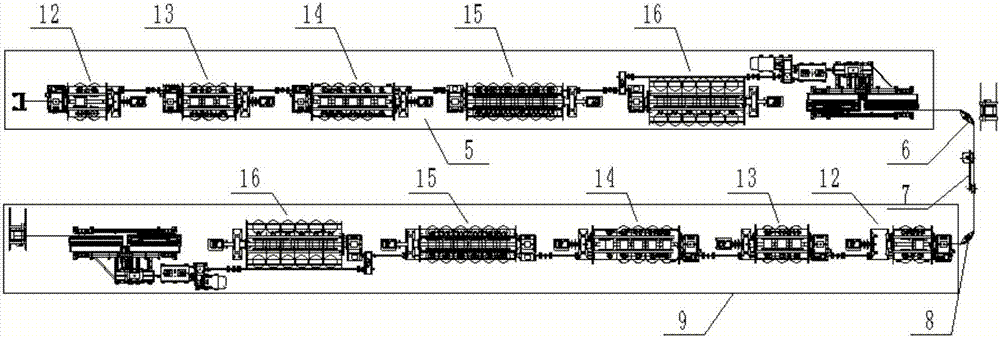

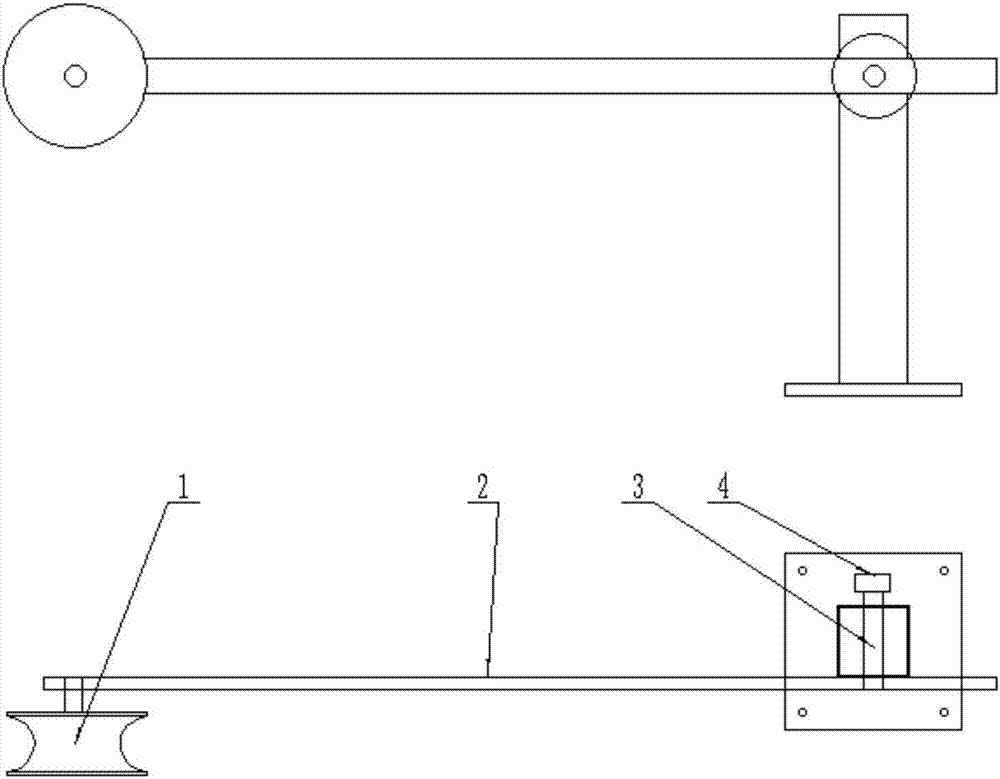

[0028] Such as Figure 1-3 As shown, according to an embodiment of the present invention, a double-machine series twisting method for a large cross-section concentric conductor of a submarine cable, the method includes the following steps:

[0029] 1) Put the ordinary 91-core concentric conductor prepared by stranding machine one 5 into the entrance of stranding machine two 9 through steering mechanism one 6, electrical synchronization controller 7 and steering mechanism two 8 in sequence;

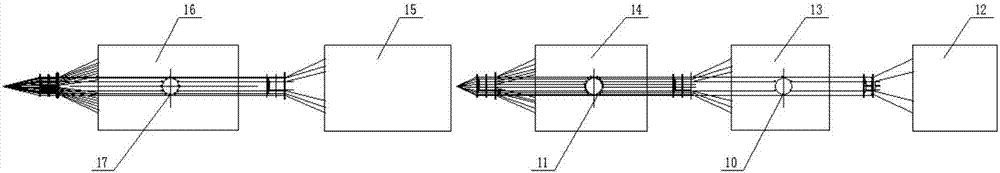

[0030] 2) Set the 6-core stranded body and the 12-core stranded body to the same speed and direction of rotation, put the 6-core stranded body into the 6-core synchronous threading tube 10, and then pass them into the 12-core stranded body's wire-passing tube together , making 18-core combined twisted body;

[0031] 3) Set the 18-core combined stranded body and the 18-core stranded body prepared in step 2) to the same speed and direction of rotation, and put the 18-core combined stranded ...

Embodiment 2

[0039] A double-machine serial twisting method for large-section concentric conductors of submarine cables, said method comprising the following steps:

[0040] 1) Lead out the ordinary 91-core concentric conductor prepared by stranding machine 1 through the traction wheel and store it on the finished wire take-up reel or outer receiving wire tray, and then pull the 91-core concentric conductor to the stranded wire again The entrance of Machine 1 5;

[0041] 2) Set the 6-core stranded body and the 12-core stranded body to the same speed and direction of rotation, put the 6-core stranded body into the 6-core synchronous threading tube 10, and then pass them into the 12-core stranded body's wire-passing tube together , making 18-core combined twisted body;

[0042] 3) Set the 18-core combined stranded body and the 18-core stranded body prepared in step 2) to the same speed and direction of rotation, and put the 18-core combined stranded body into the 18-core synchronous threadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com