A rotor for an electric motor or generator

A motor and generator technology, applied in the field of rotors, can solve the problem of high magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

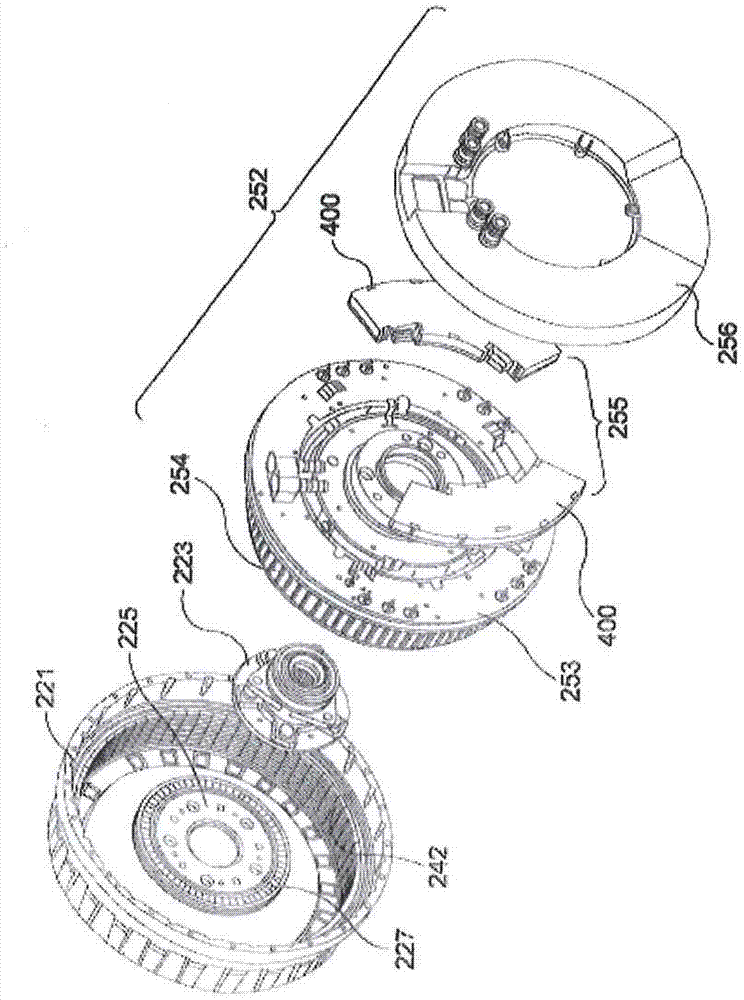

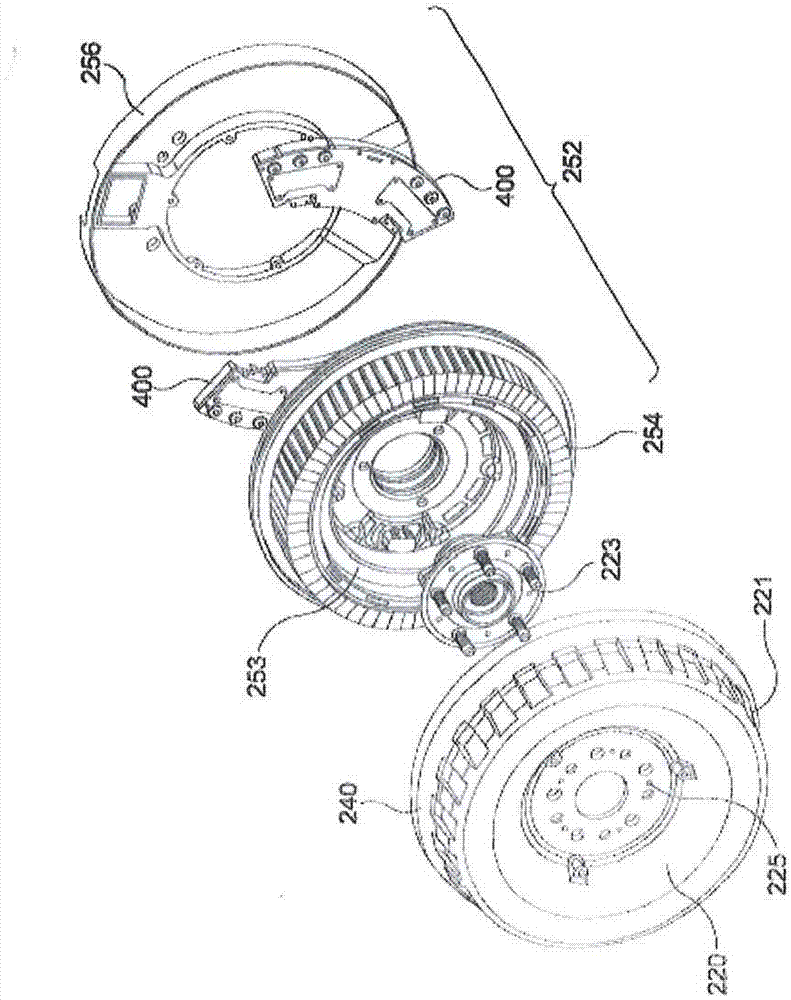

[0017] figure 1 and figure 2 An electric motor assembly is shown with an electric motor having a rotor according to the invention, wherein the electric motor assembly includes built-in electronics and is configured for use as an in-wheel or in-wheel motor configured to accommodate a wheel. But the invention can be incorporated into any form of electric motor. The electric motor can also be designed as a generator.

[0018] figure 2 Shown from the opposite side with the figure 1 An exploded view of the same components.

[0019] Such as figure 1 and figure 2 As shown, in order to implement the present embodiment, the in-wheel motor includes a stator 252 and a rotor 240 . The stator 252 preferably includes a main stator frame 253 containing cooling fins, a doubler coil 254 and an electronics module 255 mounted within the rear of the main stator frame 253 to drive the coil. Coils 254 are formed on the stator tooth laminations to form the coil windings. The stator teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com