Novel friction clutch and separating and combining device thereof

A friction clutch, clutch technology, applied in friction clutches, clutches, mechanical drive clutches, etc., can solve the problems of poor stability, low transmission efficiency, and good heat dissipation of dry multi-plate clutches, and achieve stable clutch function and large transmission torque. , the effect of good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

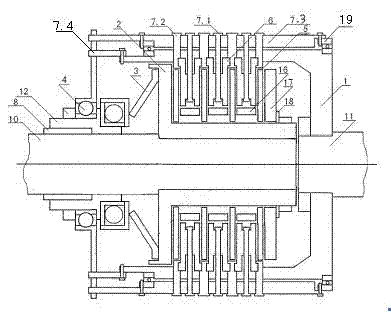

[0028] Friction clutch, the structure of which is as figure 1 with Figure 4 As shown, it includes outer rotor cover 1, inner rotor sleeve 2, release bearing 4, release bearing sliding sleeve 12, fixed bushing 8, inner friction plate 5, outer friction plate 6, thick washer 16, washer 18, inner rotor Disc baffle 17, driving shaft 11, driven shaft 10, diaphragm spring 3 and separation coupling device 7.

[0029] Among them, the inner rotor sleeve 2 is set on the driven shaft 10, and is connected with a key. The inner rotor sleeve 2 is covered with 4 inner friction plates 5, and the inner teeth of the claws on the inner friction plate 5 are connected with the inner rotor sleeve 2. It is connected by spline fit, and there is a thick washer 16 between every two inner friction plates 5, which is used to increase the space distance between the two inner friction plates 5. The outer side of the inner rotor sleeve 2 is covered with an inner rotor baffle plate 17, The outer side of th...

Embodiment 2

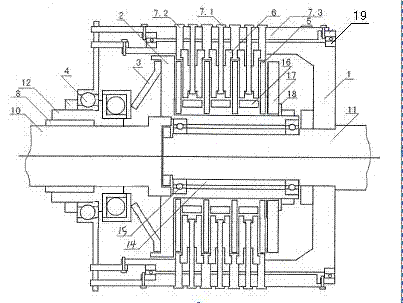

[0034] Friction clutch, the structure of which is as figure 2 with Figure 4 As shown, it includes outer rotor cover 1, inner rotor sleeve 2, release bearing 4, release bearing sliding sleeve 12, fixed bushing 8, inner friction plate 5, outer friction plate 6, thick washer 16, washer 18, inner rotor Disc baffle 17, driving shaft 11, driven shaft 10, diaphragm spring 3 and separation coupling device 7.

[0035] Wherein, the inner moving disk sleeve 2 is set on the thinner end of the driving shaft 11, two small bearings 15 are installed at both ends of the inner hole of the inner moving disk sleeve 2, and a bushing 14 is arranged between the two small bearings 15, and the inner moving disk The disc sleeve 2 is connected with the driven shaft 10 by a spline fit, and the inner drive disc sleeve 2 is covered with 4 inner friction plates 5, and the inner teeth of the protruding claws on the inner friction plates 5 are connected with the inner drive disc sleeve 2 by a spline fit. ...

Embodiment 3

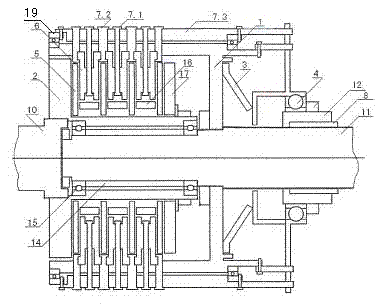

[0038] Friction clutch, the structure of which is as image 3 with Figure 4 As shown, it includes outer rotor cover 1, inner rotor sleeve 2, release bearing 4, release bearing sliding sleeve 12, fixed bushing 8, inner friction plate 5, outer friction plate 6, thick washer 16, washer 18, inner rotor Disc baffle 17, driving shaft 11, driven shaft 10, diaphragm spring 3 and separation coupling device 7.

[0039] Wherein, the inner moving disk sleeve 2 is set on the thinner end of the driving shaft 11, two small bearings 15 are installed at both ends of the inner hole of the inner moving disk sleeve 2, and a bushing 14 is arranged between the two small bearings 15, and the inner moving disk The disc sleeve 2 is connected with the driven shaft 10 by a spline fit, and the inner drive disc sleeve 2 is covered with 4 inner friction plates 5, and the inner teeth of the protruding claws on the inner friction plates 5 are connected with the inner drive disc sleeve 2 by a spline fit. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com