A medium speed coal mill

A coal mill, medium-speed technology, applied in the field of coal grinding equipment in coal-fired thermal power plants, can solve the problems of reducing the service life of the grinding parts, increasing the external wear of the grinding roller sleeve, affecting the output of the coal mill, etc. The effect of increasing the grinding area, improving the service life and increasing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

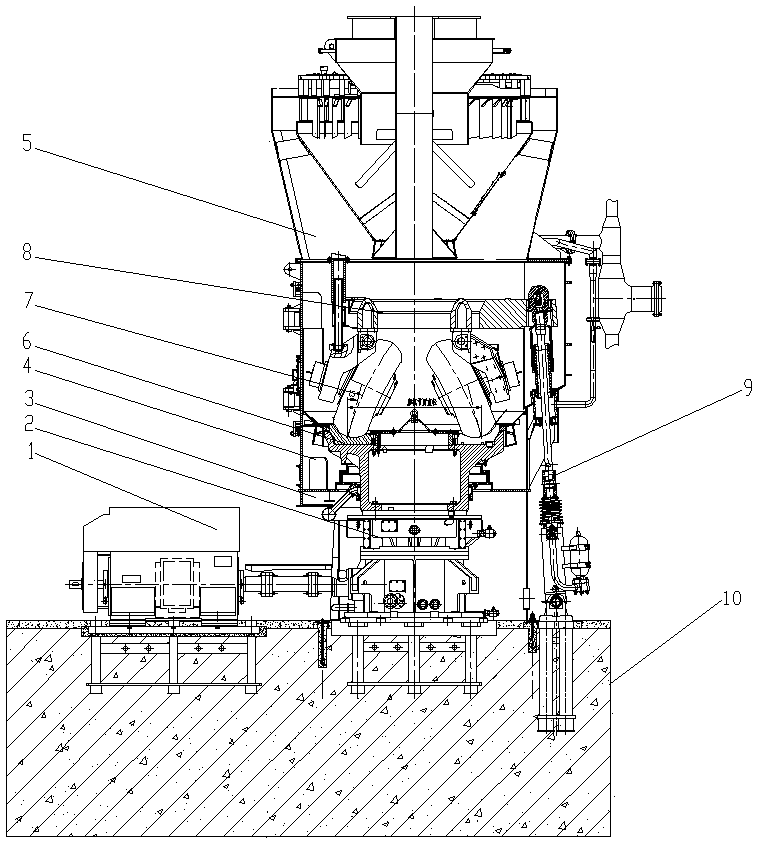

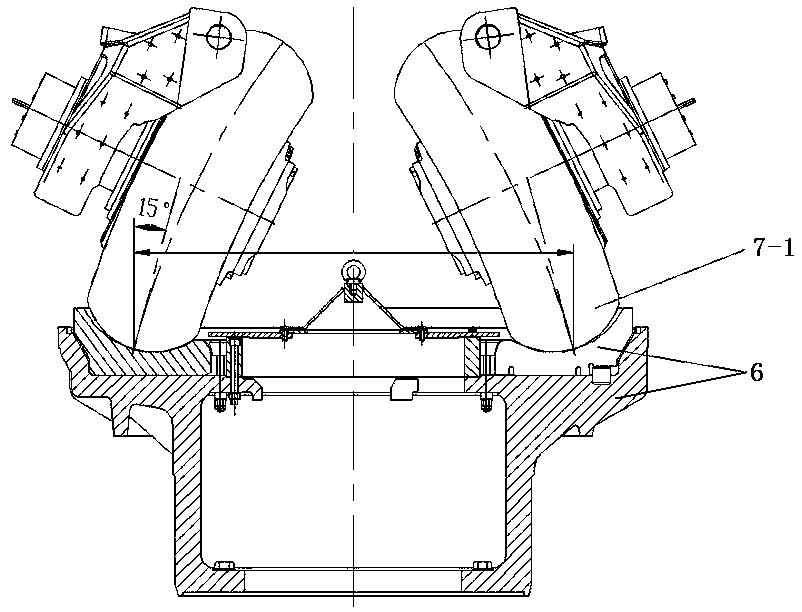

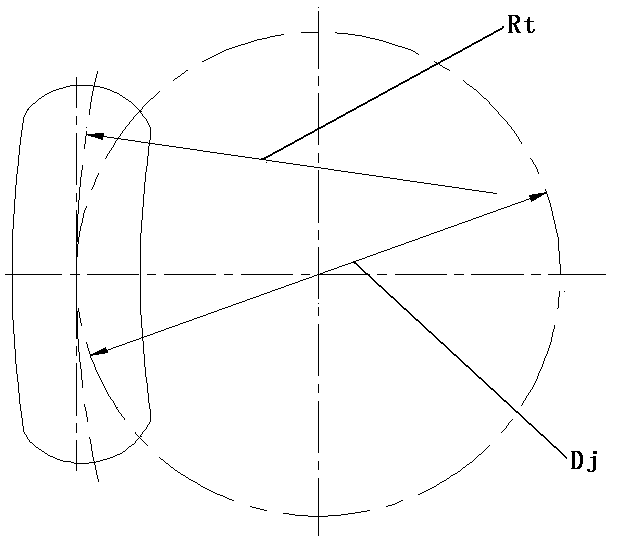

[0013] refer to figure 1 , figure 2 , image 3 , the medium-speed coal mill of the present invention includes a main motor 1, a reducer 2, a lower frame body 3, a middle frame body 4, a separator 5, a grinding disc assembly 6, a grinding roller assembly 7, a pressurizing device 8, a pull rod mechanism 9, a base 10. Hydraulic system (not shown), slag discharge device (not shown), lubrication system (not shown). The improvement made is that the shape of the grinding roller sleeve 7-1 assembled by the grinding roller is tire-shaped and centripetal arc bowl-shaped (the grinding line is still arc-shaped), and the curvature radius of the middle diameter Rt of the grinding roller sleeve is taken as The pitch circle diameter Dj is 3000 times, and the running track of the grinding roller is consistent with the middle diameter of the grinding track of the grinding disc.

Embodiment 2

[0015] refer to figure 1 , figure 2 , image 3 , the medium-speed coal mill of the present invention includes a main motor 1, a reducer 2, a lower frame body 3, a middle frame body 4, a separator 5, a grinding disc assembly 6, a grinding roller assembly 7, a pressurizing device 8, a pull rod mechanism 9, a base 10. Hydraulic system (not shown), slag discharge device (not shown), lubrication system (not shown). The improvement made is that the shape of the grinding roller sleeve 7-1 assembled by the grinding roller is tire-shaped and centripetal arc bowl-shaped (the grinding line is still arc-shaped), and the curvature radius of the middle diameter Rt of the grinding roller sleeve is taken as The pitch circle diameter Dj is 2000 times, and the running track of the grinding roller is consistent with the middle diameter of the grinding track of the grinding disc.

Embodiment 3

[0017] refer to figure 1 , figure 2 , image 3 , the medium-speed coal mill of the present invention includes a main motor 1, a reducer 2, a lower frame body 3, a middle frame body 4, a separator 5, a grinding disc assembly 6, a grinding roller assembly 7, a pressurizing device 8, a pull rod mechanism 9, a base 10. Hydraulic system (not shown), slag discharge device (not shown), lubrication system (not shown). The improvement made is that the shape of the grinding roller sleeve 7-1 assembled by the grinding roller is tire-shaped and centripetal arc bowl-shaped (the grinding line is still arc-shaped), and the curvature radius of the middle diameter Rt of the grinding roller sleeve is taken as The pitch circle diameter Dj is 5000 times, and the running track of the grinding roller is consistent with the middle diameter of the grinding track of the grinding disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com