Dish-shaped parts rotary end surface supporting roller differential mechanism

A technology of disc parts and differential mechanisms, applied in the direction of support, metal processing machinery parts, clamping, etc., can solve the problems of large driving torque, surface wear of drag rollers, poor motion stability, etc., to reduce surface wear and reduce Sliding friction and the effect of reducing the difference in linear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

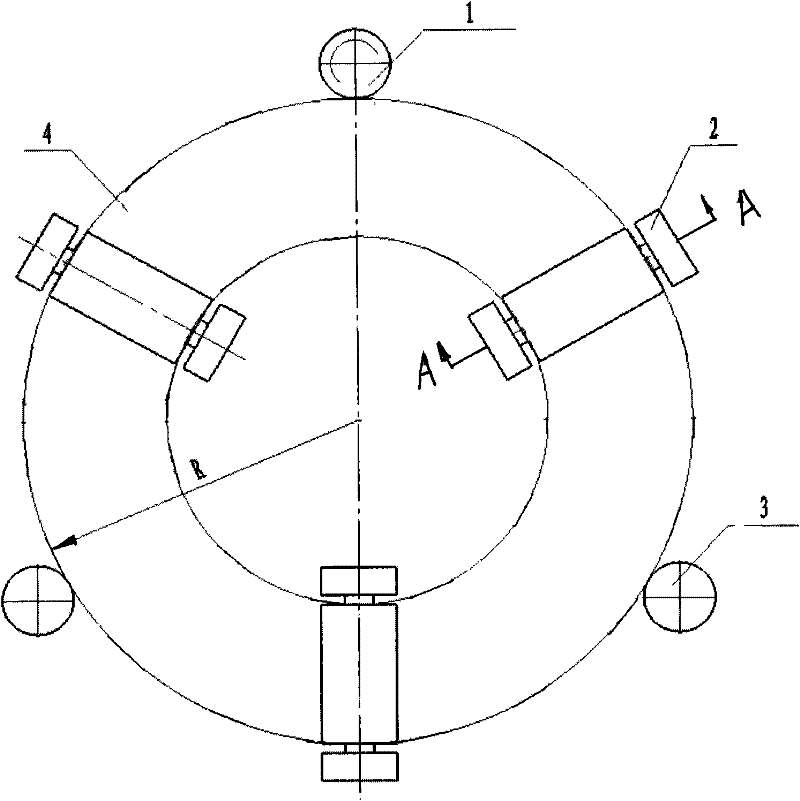

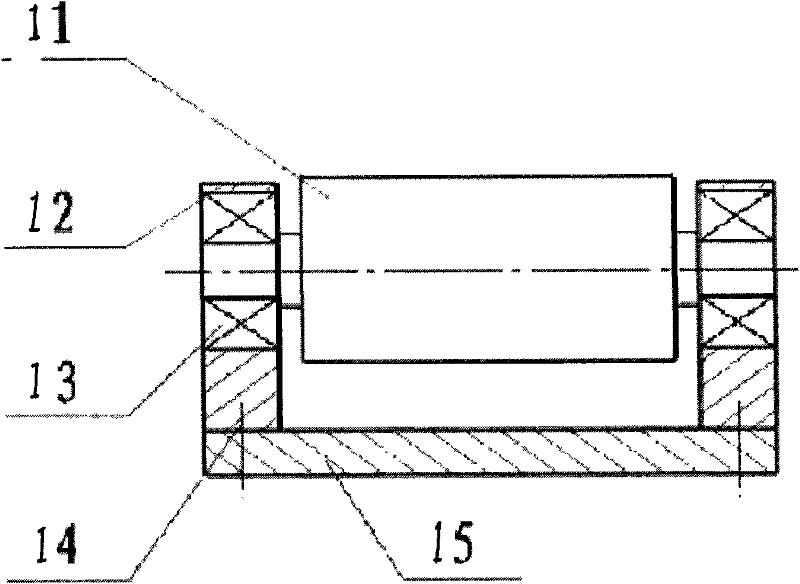

[0014] The invention is in figure 1 It is realized by replacing the dragging roller mechanism in the existing disc-type parts rotating end support mechanism shown. The specific implementation is as follows:

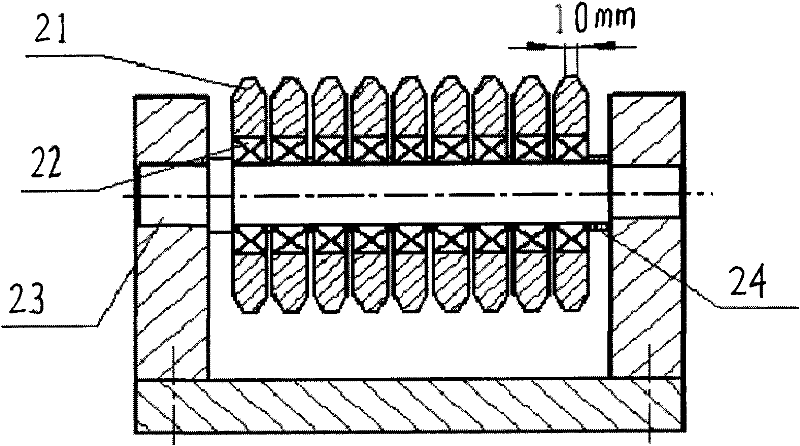

[0015] The rotating end support mechanism of disk parts includes: the main driving wheel for driving the rotation of the disk parts, which drives the rotation of the disk parts through the friction with the outer peripheral surface of the disk parts; Function; the drag roller mechanism is located under the end face of the disc parts and plays a supporting role. The number of the drag roller mechanisms is 3 and is evenly distributed; the drag roller mechanism includes: a bottom plate, a bracket fixedly connected to the bottom plate, and a fixed bracket in the middle of the bracket. The shaft and the fixed shaft are fixedly connected with the support; the rolling bearings arranged side by side on the fixed bearings, the number of rolling bearings is 9; the spacers are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com