Plate feeding table

A technology for feeding plates and worktables, applied in conveyors, mechanical conveyors, object supply and other directions, can solve problems such as troublesome left and right adjustment, laborious plates, etc., and achieve the effects of convenient replacement, reduced surface wear and low friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

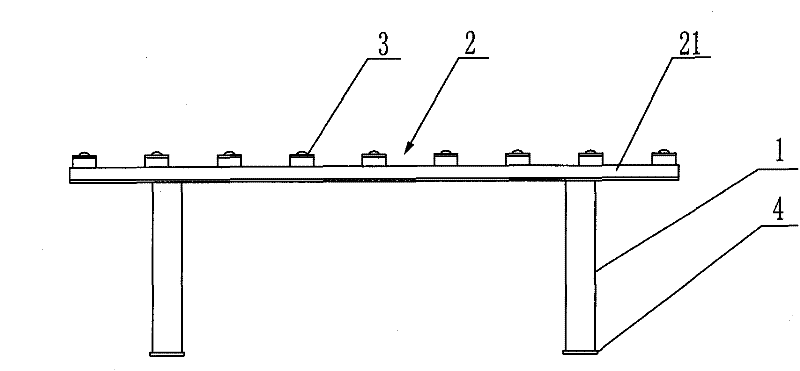

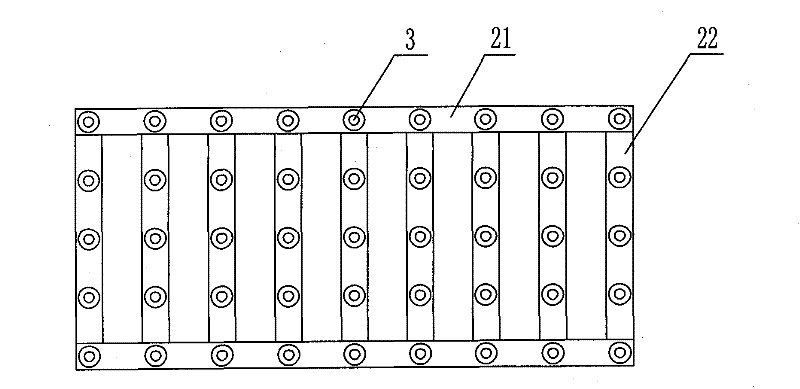

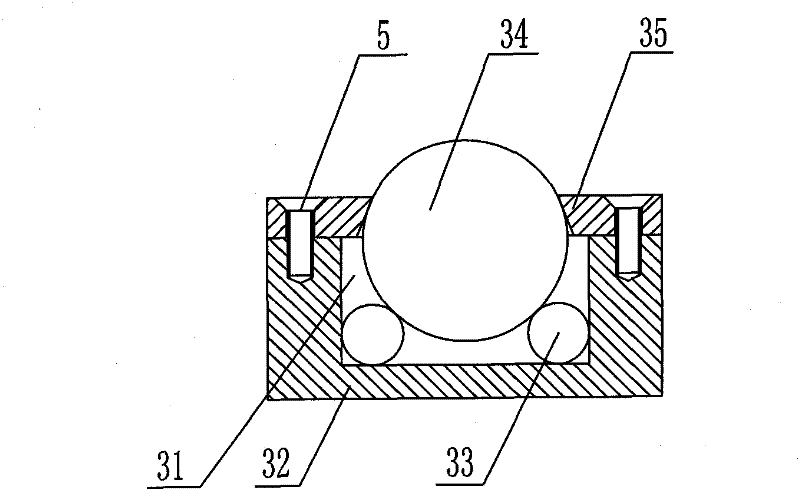

[0019] Such as figure 1 , 2 As shown in , 3, a board delivery platform includes a bracket 1, and a workbench 2 is set on the bracket 1. The workbench 2 is composed of two beams 21 and several longitudinal beams 22, and the several longitudinal beams 22 are welded in parallel to each other. Between the two beams, all the longitudinal beams 22 are welded and fixed vertically to the beam 21; the beams 21 and the longitudinal beams 22 can be channel steel or steel plates. Of course, the workbench can also be replaced by steel plates; the workbench 2 is provided with a supporting transmission device 3, which includes a ball seat 32 with a mounting groove 31, and a supporting transmission ball 33 is set in the mounting groove 31. There are four balls 33, which are installed in the four inner corners of the mounting groove 31 of the ball seat 32 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com