Method for preparing ethanol from cellulose-containing raw material

A technology of cellulose and cellulase, applied in the direction of microorganism-based methods, biochemical equipment and methods, biofuels, etc., can solve the problems of low ethanol yield, achieve increased ethanol yield, increase yield, and improve equipment The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

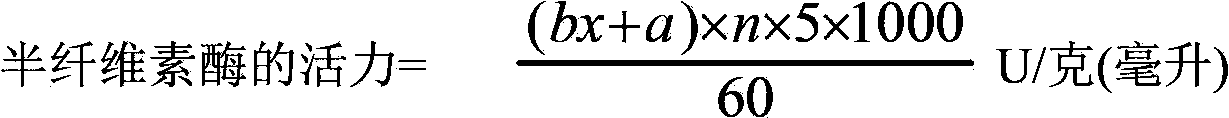

Method used

Image

Examples

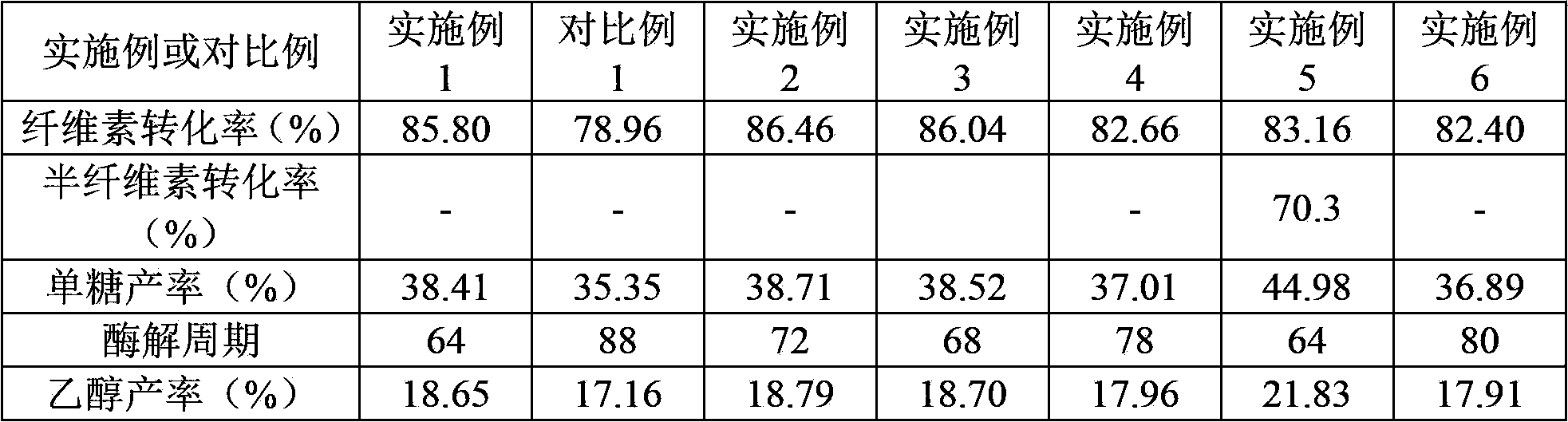

Embodiment 1

[0062] This example is used to illustrate the method of the present invention for producing ethanol using cellulose-containing raw materials.

[0063] (1) Pretreatment of cellulose-containing raw materials

[0064] Cut 1000 kg of corn stalks without impurities (moisture content 10% by weight) into small pieces not exceeding 1.2 cm × 0.5 cm × 1.0 cm, maintain a pressure of 1.0 MPa at 180 ° C for 5 minutes, and then release the pressure to complete steam explosion . A total of 1800 kg of steam explosion waste (with a water content of 50% by weight) was obtained.

[0065] Determination of the total weight of cellulose and the total weight of hemicellulose in the resulting solid steam explosion product:

[0066] Take 10 grams of the above-mentioned steam explosion product and dry it at 45° C. to a constant weight of 5 grams, weigh 300.0 mg of the dried steam explosion product, and place it in a 100-milliliter dry Erlenmeyer flask weighing 80 grams. Add 3.00 ml of sulfuric acid ...

Embodiment 2

[0077] This example is used to illustrate the method of the present invention for producing ethanol using cellulose-containing raw materials.

[0078] Prepare ethanol according to the method of Example 1, the difference is that in the enzymolysis step (2), in the main enzymolysis stage, the steam explosion product is adjusted to a pH value of 5, and after heating to 52°C, the main enzyme is continuously added In the first enzymolysis tank of the enzymolysis stage, the addition of the steam explosion product is 25 kg / hour, and the cellulase is continuously added to the enzymolysis tank of the first enzymolysis stage of the main enzymolysis stage. When the enzymatic hydrolysis product in the first enzymatic hydrolysis tank starts to flow into the enzymatic hydrolysis tank of the second enzymatic hydrolysis stage connected in series with the first place, and at 52°C, add cellulase continuously to the enzymatic hydrolysis of the second enzymatic hydrolysis stage In the tank, the a...

Embodiment 3

[0082] This example is used to illustrate the method of the present invention for producing ethanol using cellulose-containing raw materials.

[0083] Prepare ethanol according to the method of Example 1, the difference is that in the enzymolysis step (2), in the main enzymolysis stage, the steam explosion product is adjusted to a pH value of 5, and after heating to 52°C, the main enzyme is continuously added In the first enzymolysis tank of the enzymolysis stage, the addition of the steam explosion product is 26.47 kg / hour, and the cellulase is continuously added to the enzymolysis tank of the first enzymolysis stage of the main enzymolysis stage. When the enzymatic hydrolysis product in the first enzymatic hydrolysis tank starts to flow into the enzymatic hydrolysis tank of the second enzymatic hydrolysis stage connected in series with the first place, and at 52°C, add cellulase continuously to the enzymatic hydrolysis of the second enzymatic hydrolysis stage In the tank, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com