Escherichia coli fermentation medium and fermentation technology for producing succinic acid

A fermentation medium, Escherichia coli technology, applied in fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of reducing the production cost of succinic acid, low sugar-acid conversion rate, long fermentation time, etc., to achieve rich carbon sources and Effects of nitrogen source, shortened culture time, and increased cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

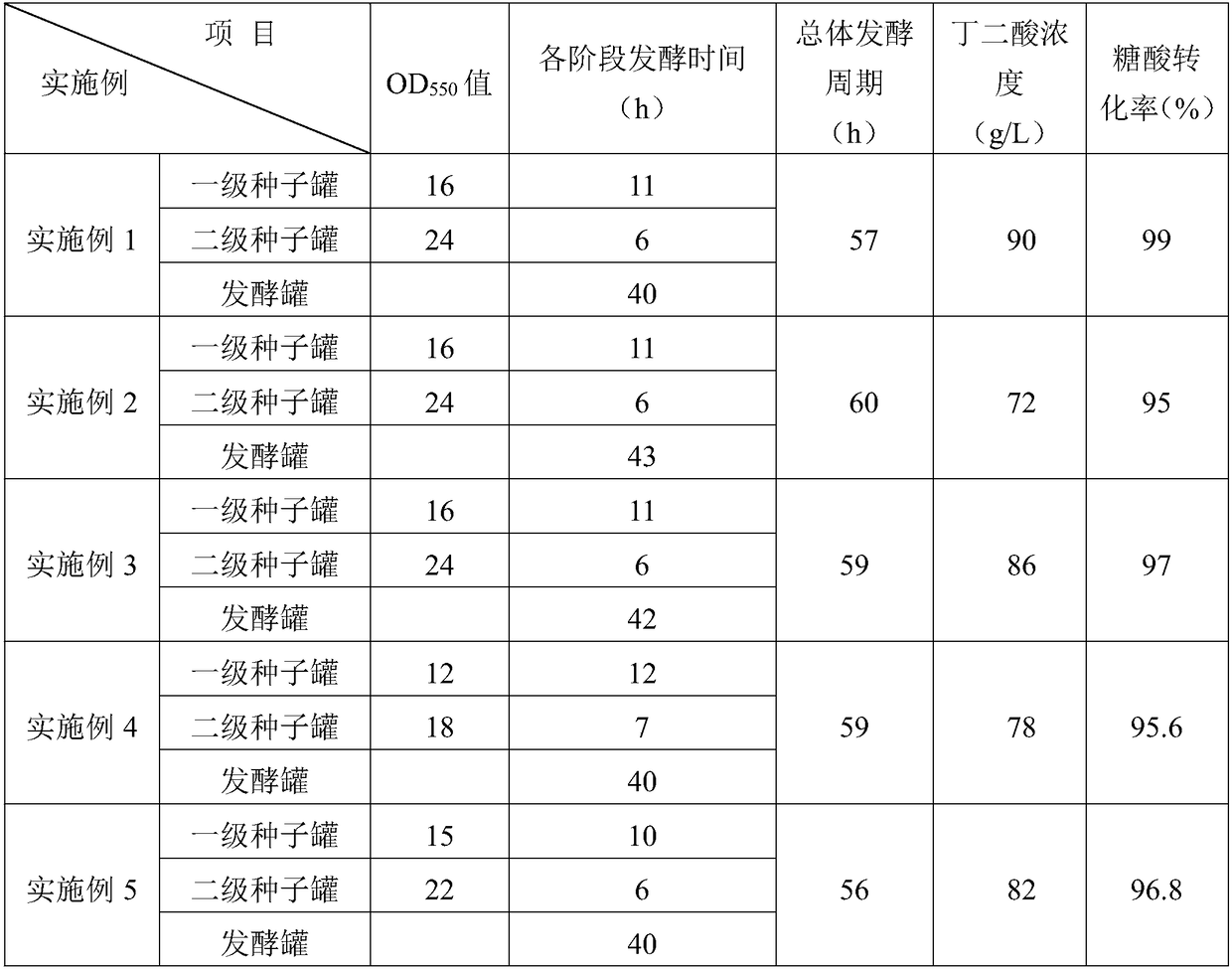

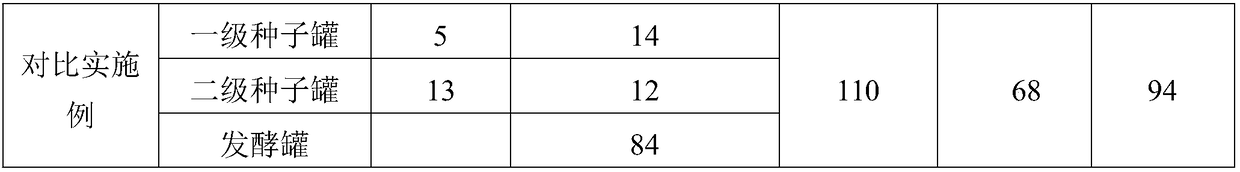

Embodiment 1

[0041] After Escherichia coli (E.coli) was activated, it was transferred into a primary seed tank (1m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 0.85vvm, the DO is controlled at 25%, the stirring speed is 350r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 11h;

[0042] Escherichia coli (E.coli) was transferred to the secondary seed tank (20m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 1.1vvm, the DO is controlled at 15%, the stirring speed is 200r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 6h;

[0043] The seed medium components in the primary seed tank and the secondary seed tank are: glucose: 20g / L, peptone: 10g / L, KH 2 PO 4 : 1g / L, MgSO 4 ·7H 2 O: 0.5g / L, add 5mol / LNaOH external source flow to adjust the pH value of the culture medium to 7.0, the culture medium in the primary seed tank is adjusted to half the volume of the p...

Embodiment 2

[0047] The only difference between this embodiment and embodiment 1 is that the formula ratio of the fermentation medium in the fermenter is adjusted.

[0048] After Escherichia coli (E.coli) was activated, it was transferred into a primary seed tank (1m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 0.85vvm, the DO is controlled at 25%, the stirring speed is 350r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 11h;

[0049] Escherichia coli (E.coli) was transferred to the secondary seed tank (20m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 1.1vvm, the DO is controlled at 15%, the stirring speed is 200r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 6h;

[0050] The seed medium components in the primary seed tank and the secondary seed tank are: glucose: 20g / L, peptone: 10g / L, KH 2 PO 4 : 1g / L, MgSO 4 ·7H 2 O: 0.5g / L, add 5mol / LNaOH ext...

Embodiment 3

[0054] The only difference between this embodiment and embodiment 1 is that the formula ratio of the fermentation medium in the fermenter is adjusted.

[0055] After Escherichia coli (E.coli) was activated, it was transferred into a primary seed tank (1m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 0.85vvm, the DO is controlled at 25%, the stirring speed is 350r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 11h;

[0056] Escherichia coli (E.coli) was transferred to the secondary seed tank (20m 3 ) in the seed medium, the temperature is controlled at 31°C, the air volume is controlled at 1.1vvm, the DO is controlled at 15%, the stirring speed is 200r / min, the tank pressure is 0.05Mpa, and the aerobic fermentation is 6h;

[0057] The seed medium in the primary seed tank and the secondary seed tank is: glucose: 20g / L, peptone: 10g / L, KH 2 PO 4 : 1g / L, MgSO 4 ·7H 2 O: 0.5g / L, add 5mol / LNaOH external source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com