A kind of preparation method of metal organic framework material mil-100 (fe)

A metal organic framework and organic ligand technology, applied in the direction of iron organic compounds, can solve the problems of low product yield, difficult industrial production, harsh synthesis conditions, etc., to overcome low yield, reduce synthesis energy consumption, quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 2.02g Fe(NO 3 ) 3 .9H 2 O. Add 0.70g of 1,3,5-benzenetricarboxylic acid into a three-necked flask filled with 5mL of deionized water, stir it magnetically for about 30 minutes, reflux and condense, raise the temperature to 95°C and keep it at a constant temperature for 12 hours. The selected reactor is a three-necked flask Add a reflux condenser. After the reaction, the sample was filtered, washed with a sufficient amount of deionized water, and placed in a drying oven for constant temperature drying for 5 hours.

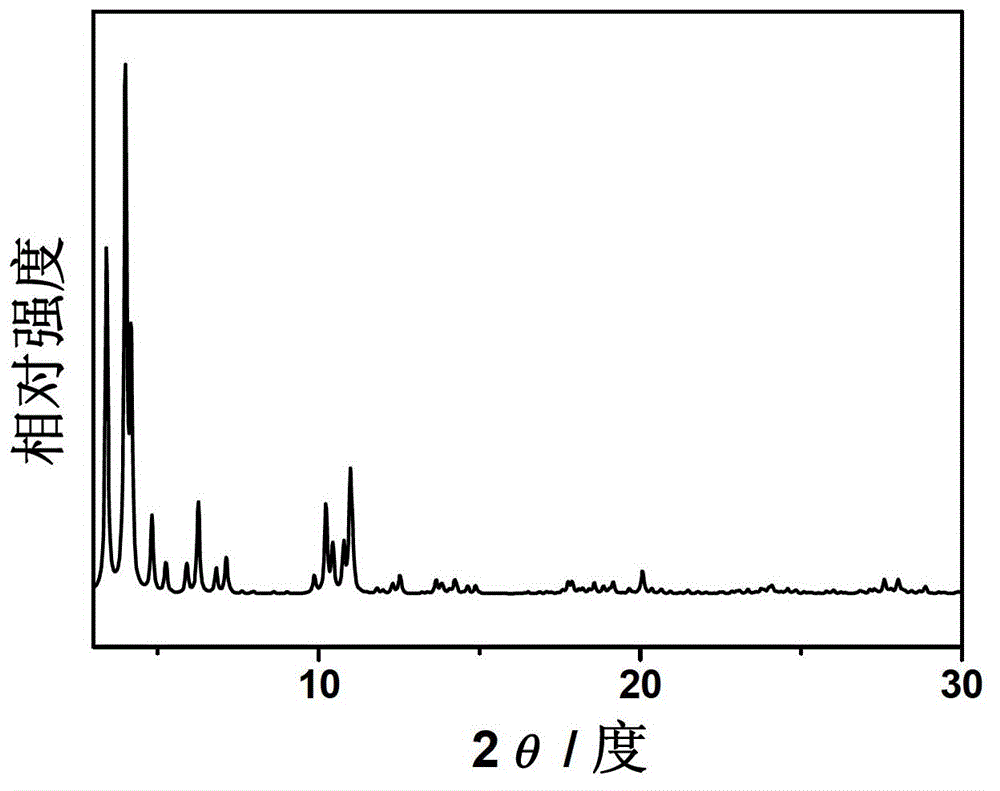

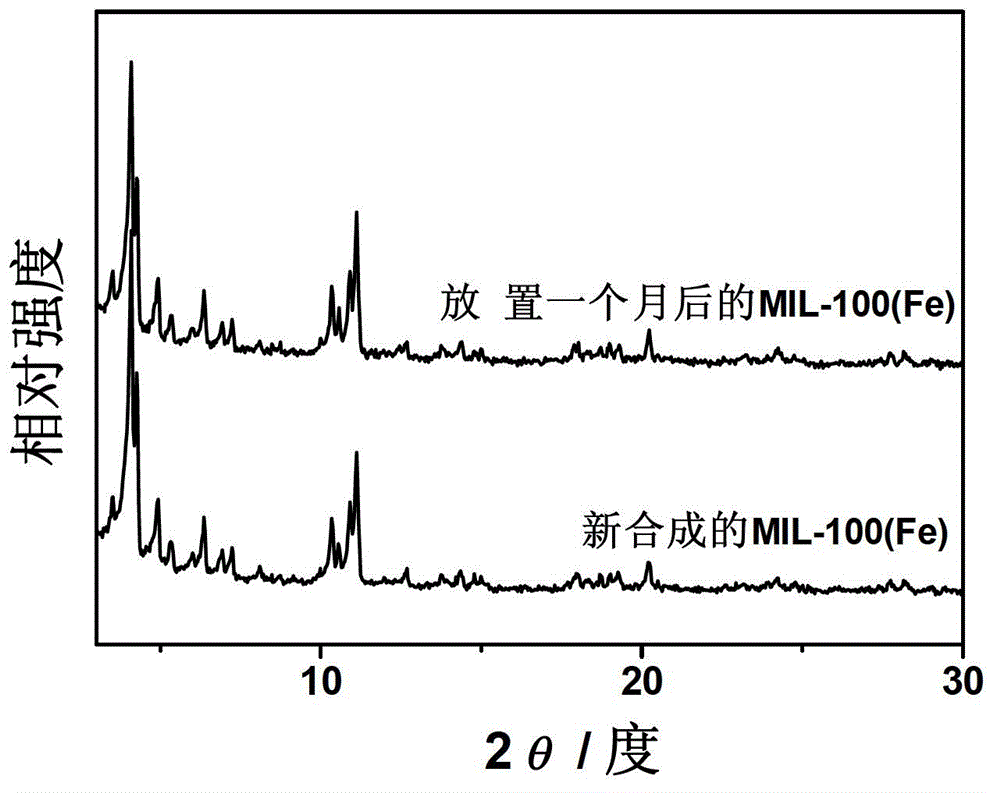

[0021] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 70°C for 10h, then treat with 30mmol / L ammonium fluoride solution at 80°C for 10h, and finally wash fully with deionized water. The drying temperature was 150°C, and the drying time was 10 hours to obtain a light orange powder. Through XRD analysis, its characteristic peak is consistent with the fitted MIL-100 (Fe) charac...

Embodiment 2

[0023] Sequentially add 0.81g FeCl 3 .6H 2 O. Add 0.51g of 1,3,5-trimethylbenzenetricarboxylate into a three-necked flask filled with 15mL of deionized water, stir it magnetically for about 30 minutes, reflux and condense, raise the temperature to 95°C and keep it at a constant temperature for 12 hours. The selected reactor Add a reflux condenser to the three-necked flask. After the reaction, the sample was filtered, washed with a sufficient amount of deionized water, and placed in a drying oven for constant temperature drying for 5 hours.

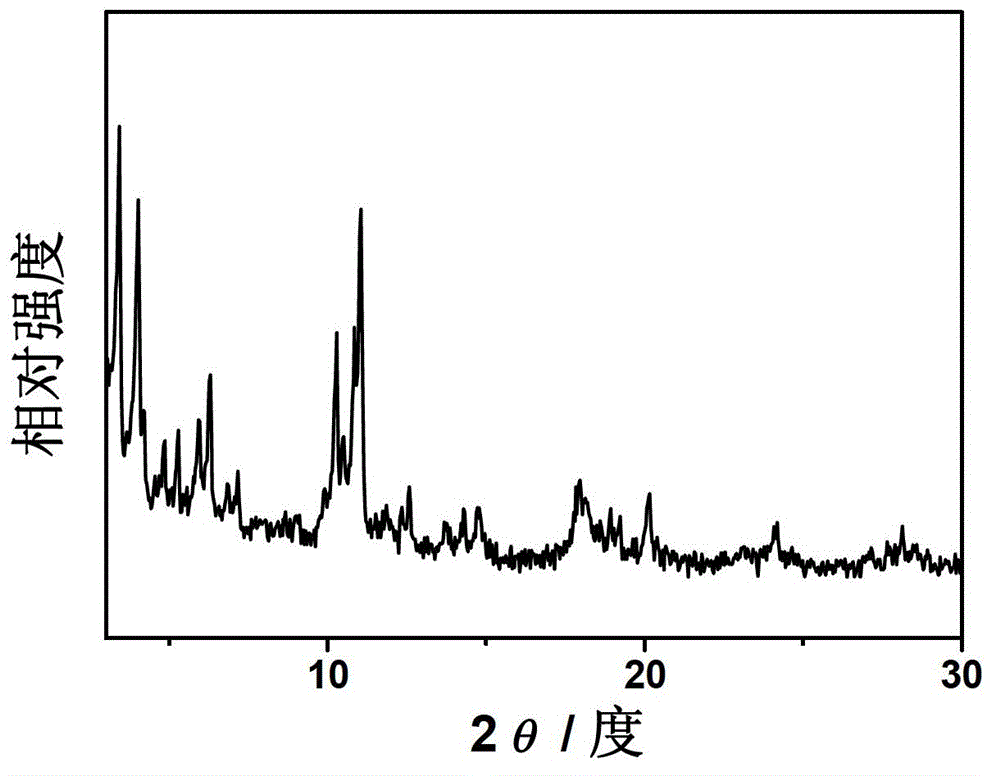

[0024] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 60°C for 15h, then treat with 40mmol / L ammonium fluoride solution at 70°C for 15h, and finally wash fully with deionized water. The drying temperature was 100°C, and the drying time was 10 hours to obtain a light orange powder. Through XRD analysis, its characteristic peak is consistent with the fitted ...

Embodiment 3

[0026] 2.02g Fe(NO 3 ) 3 .9H 2 O. Add 0.63g of 1,3,5-trimethylbenzenetricarboxylate into a three-necked flask filled with 5mL of deionized water, stir magnetically for about 30min, reflux and condense, heat up to 80°C and keep at constant temperature for 20h, the selected reactor Add a reflux condenser to the three-necked flask. After the reaction, the sample was filtered, washed with a sufficient amount of deionized water, and placed in a drying oven for constant temperature drying for 5 hours.

[0027] The dried samples were further purified with ethanol and ammonium fluoride, respectively. First, treat with absolute ethanol at 80°C for 20h, then treat with 50mmol / L ammonium fluoride solution at 60°C for 10h, and finally wash fully with deionized water. The drying temperature was 150°C, and the drying time was 5 hours to obtain a light orange powder. According to XRD analysis, its characteristic peaks are consistent with the fitted MIL-100(Fe) characteristic peaks, indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com