Potassium ion battery negative electrode material, preparation method thereof and potassium ion battery

A battery negative electrode and potassium ion technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of the first coulombic efficiency of the battery, etc., and achieve the effect of taking into account the first coulombic efficiency, taking into account the capacity, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Based on the foregoing, the present invention discloses a negative electrode material for a potassium ion battery, a preparation method thereof, and a potassium ion battery, including:

[0029] S1. Prepare the carbon molecular sieve raw material; the carbon molecular sieve is a carbon raw material with a certain pore structure, which can meet the porosity requirement of the negative electrode material of the potassium ion battery.

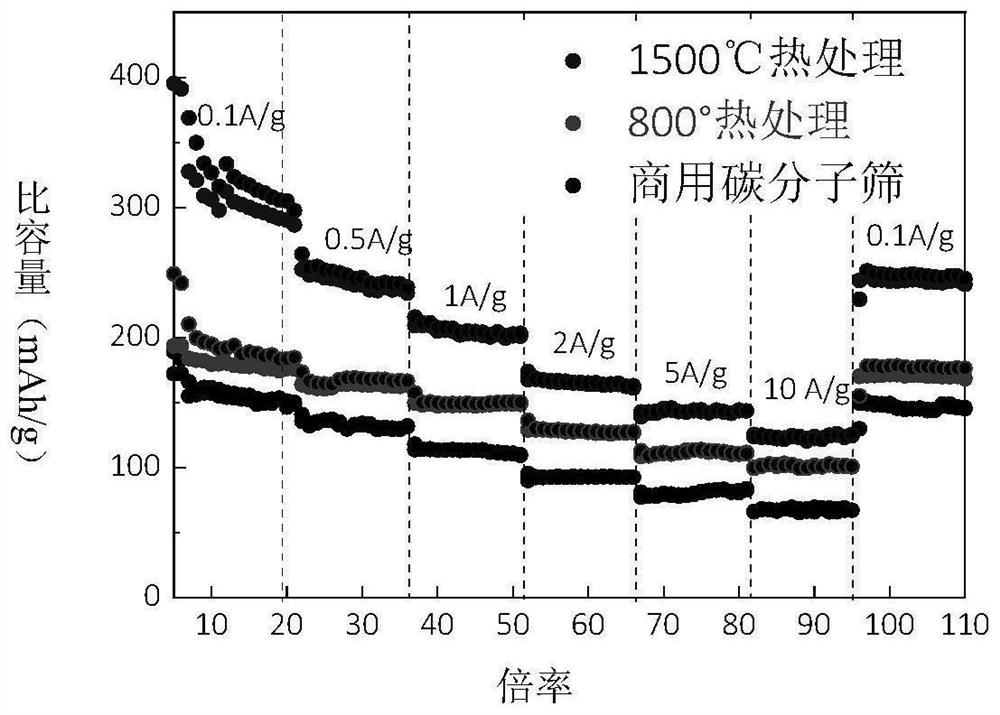

[0030] In a specific embodiment, nitrogen-producing carbon molecular sieves with a micropore diameter of 0.28-0.38nm are directly purchased as the raw material of the carbon molecular sieve. There are many kinds of commercial nitrogen-producing molecular sieves, and the pore size will be slightly different, but the first Coulombic efficiency is the same. Between 65-75%; the first coulombic efficiency after heat treatment at 800°C is 75%; the first coulombic efficiency after heat treatment at 1500°C can be greater than 85%, and the capacity is...

Embodiment 1

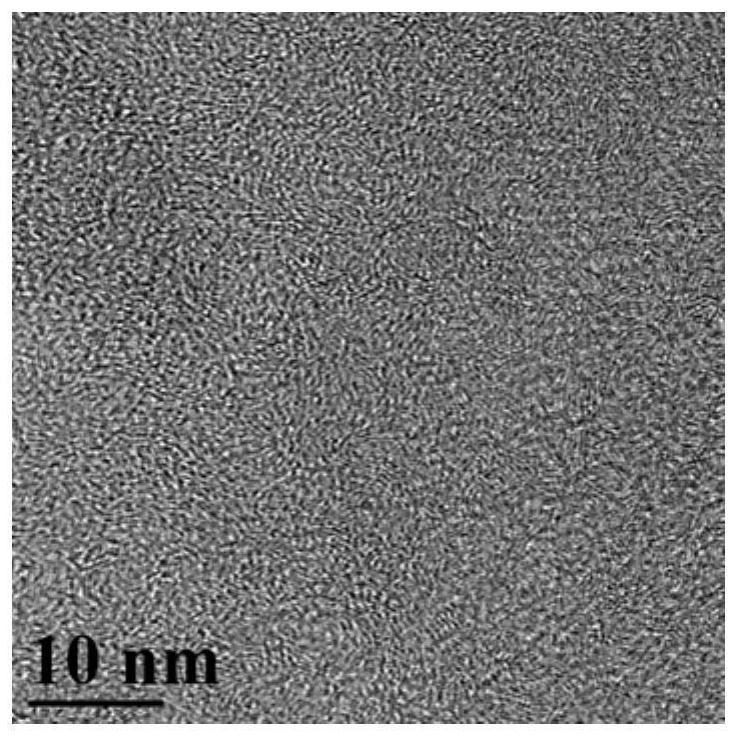

[0050] Direct purchase of nitrogen-making carbon molecular sieves with a micropore diameter of 0.28 to 0.38nm is used as the carbon molecular sieve raw material as the potassium ion negative electrode material, and the TEM diagram of the potassium ion negative electrode material is as follows figure 2 shown.

Embodiment 2

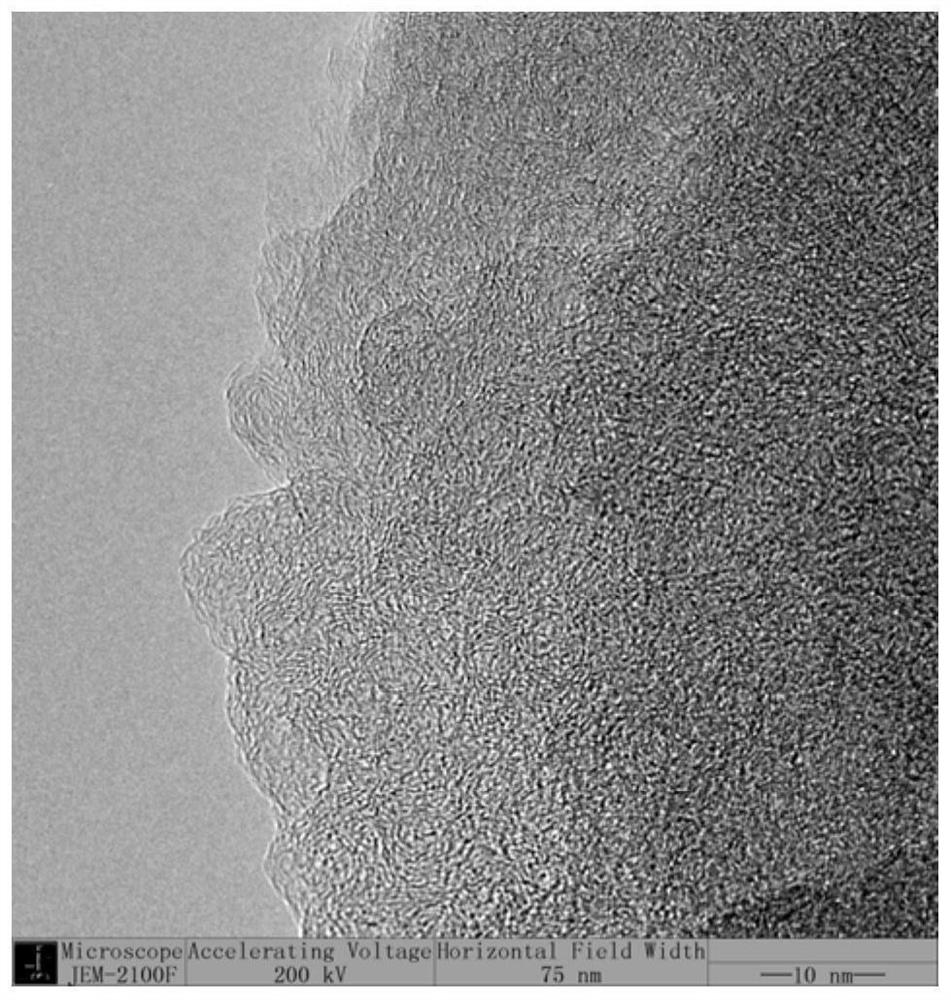

[0052] Directly purchase nitrogen-producing carbon molecular sieves with a micropore diameter of 0.28-0.38nm as the carbon molecular sieve raw material, heat the carbon molecular sieve raw material to 800°C in an atmosphere of nitrogen with a purity of 99.99%, and keep it warm for 2 hours to obtain the potassium Ionic anode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com