Dynamically synthesized KL molecular sieve without structure-directing agent, and preparation method thereof

A synthesis method and technology of directing agent, applied in the field of molecular sieves, can solve the problems of increased synthesis cost and increased processing difficulty, achieve good purity and crystallinity, easy industrial scale-up, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

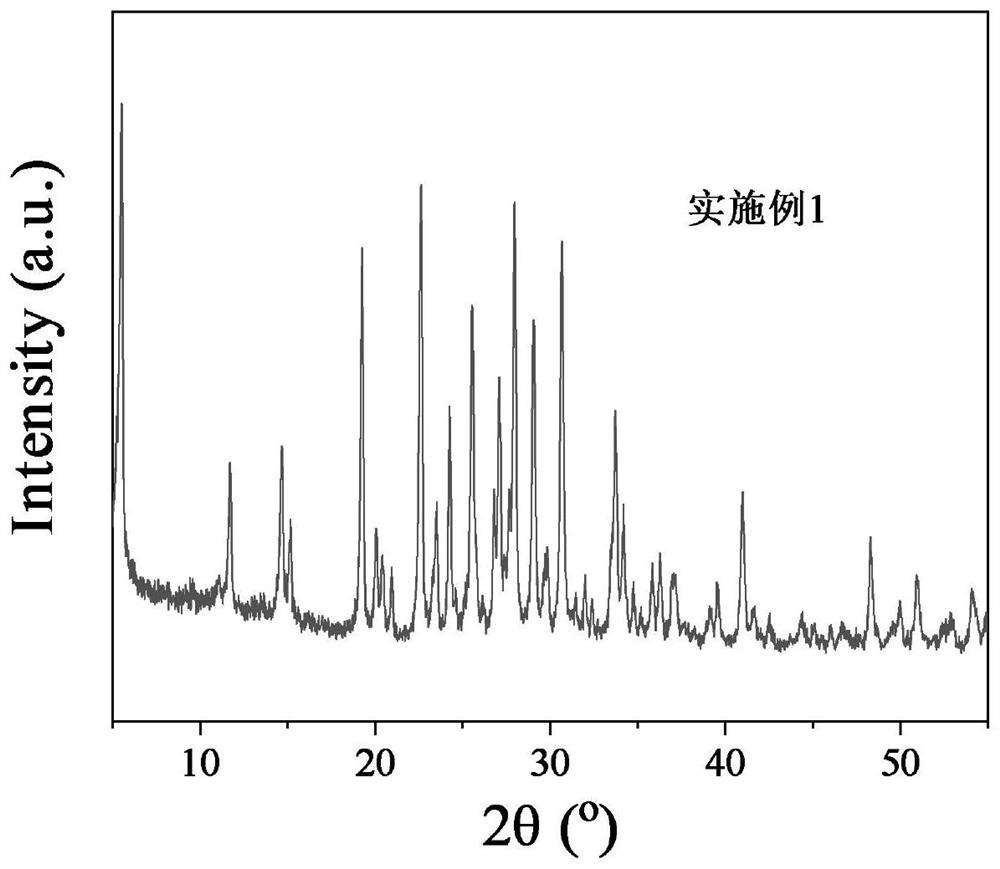

Embodiment 1

[0036] A non-zeolite structure directing agent KL dynamic synthesis method comprising the steps of: Weigh 19.52g KOH was dissolved in a small amount of water, followed by addition 4.50gAl (OH) 3 And heated to 100 deg.] C in a three-necked flask and stirred at reflux for 2h, Al (OH) 3 Complete dissolution, the solution is clear; until the solution was cooled to room temperature and transferred to a beaker, add the remaining water, stir, and then weighed 88.84g of silica sol (SiO 2 Content of 30wt.%) Was slowly added dropwise to the above solution, stirred at room temperature for 20 h aging, to obtain a sol-synthesized zeolite KL, the initial molar ratio of synthetic material to each sol 5.0K 2 O: 15.0SiO 2 : 1.0Al 2 O 3 : 292.65H 2 O. The above-synthesized sol was transferred to a PTFE lined 200mL, into a stainless steel crystallization autoclave, in a homogeneous reactor to speed 10r / min in 175 ℃ dynamic hydrothermal crystallization 24h, the resulting product was filtered off wi...

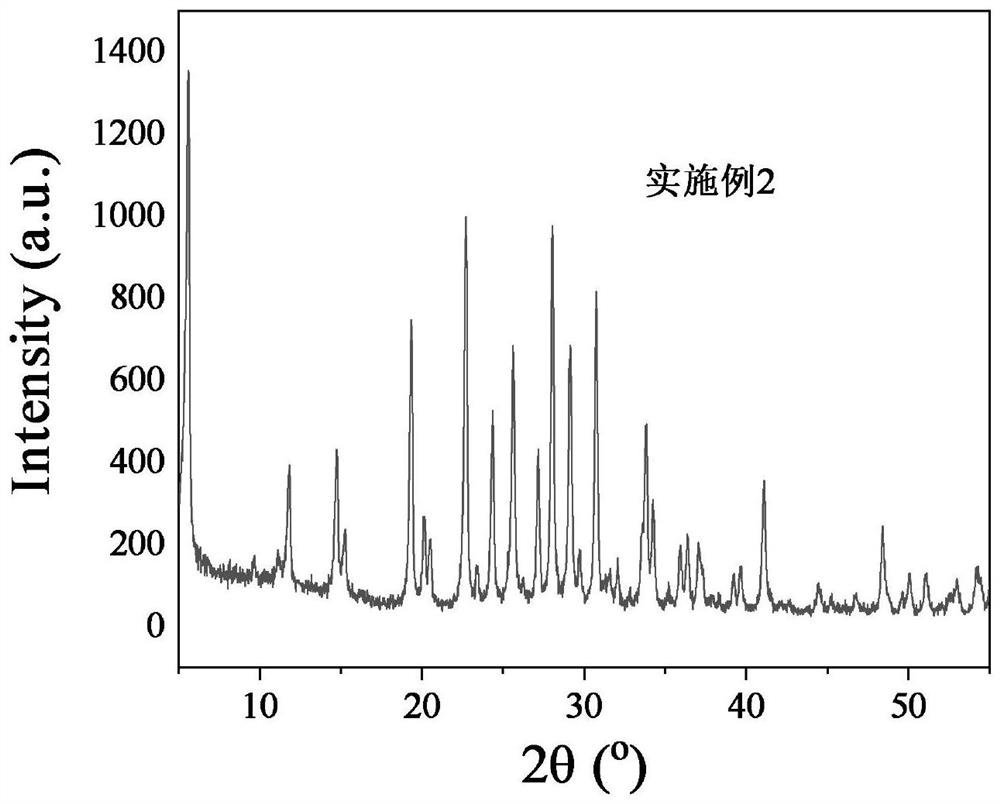

Embodiment 2

[0039] A non-zeolite structure directing agent KL dynamic synthesis method comprising the steps of: Weigh 21.47g KOH was dissolved in a small amount of water, followed by addition 4.50gAl (OH) 3 And heated to 100 deg.] C in a three-necked flask and stirred at reflux for 2h, Al (OH) 3 Complete dissolution, the solution is clear; until the solution was cooled to room temperature and transferred to a beaker, add the remaining water, stir, and then weighed 88.84g of silica sol (SiO 2 Content of 30wt.%) Was slowly added dropwise to the above solution, stirred at room temperature for 16 h aging, to obtain a sol-synthesized zeolite KL, the initial molar ratio of synthetic material to each sol 5.5K 2 O: 15.0SiO 2 : 1.0Al 2 O 3 : 292.65H 2 O. The above-synthesized sol was transferred to a PTFE lined 200mL, into a stainless steel crystallization autoclave, in a homogeneous reactor to speed 15r / min in 175 ℃ dynamic hydrothermal crystallization 24h, the resulting product was centrifuged to ...

Embodiment 3

[0044] A non-zeolite structure directing agent KL dynamic synthesis method comprising the steps of: Weigh 23.42g KOH was dissolved in a small amount of water, followed by addition 4.50gAl (OH) 3And heated to 100 deg.] C in a three-necked flask and stirred at reflux for 2h, Al (OH) 3 Complete dissolution, the solution is clear; until the solution was cooled to room temperature and transferred to a beaker, add the remaining water, stir, and then weighed 88.84g of silica sol (SiO 2 Content of 30wt.%) Was slowly added dropwise to the above solution, stirred at room temperature for 20 h aging, to obtain a sol-synthesized zeolite KL, the initial molar ratio of synthetic material to each sol 6.0K 2 O: 15.0SiO 2 : 1.0al 2 O 3 : 292.65H 2 O. The above-synthesized sol was transferred to a PTFE lined 200mL, into a stainless steel crystallization autoclave, in a homogeneous reactor to speed 15r / min in 175 ℃ dynamic hydrothermal crystallization 24h, the resulting product was filtered off wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com