Preparation method of preformed L-shaped molecular sieve

A pre-forming and molecular sieve technology, applied in the direction of L-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of reducing the effective specific surface area, blocking the pores of molecular sieves, affecting the diffusion of reactive molecules, etc., to avoid filtration difficulties , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

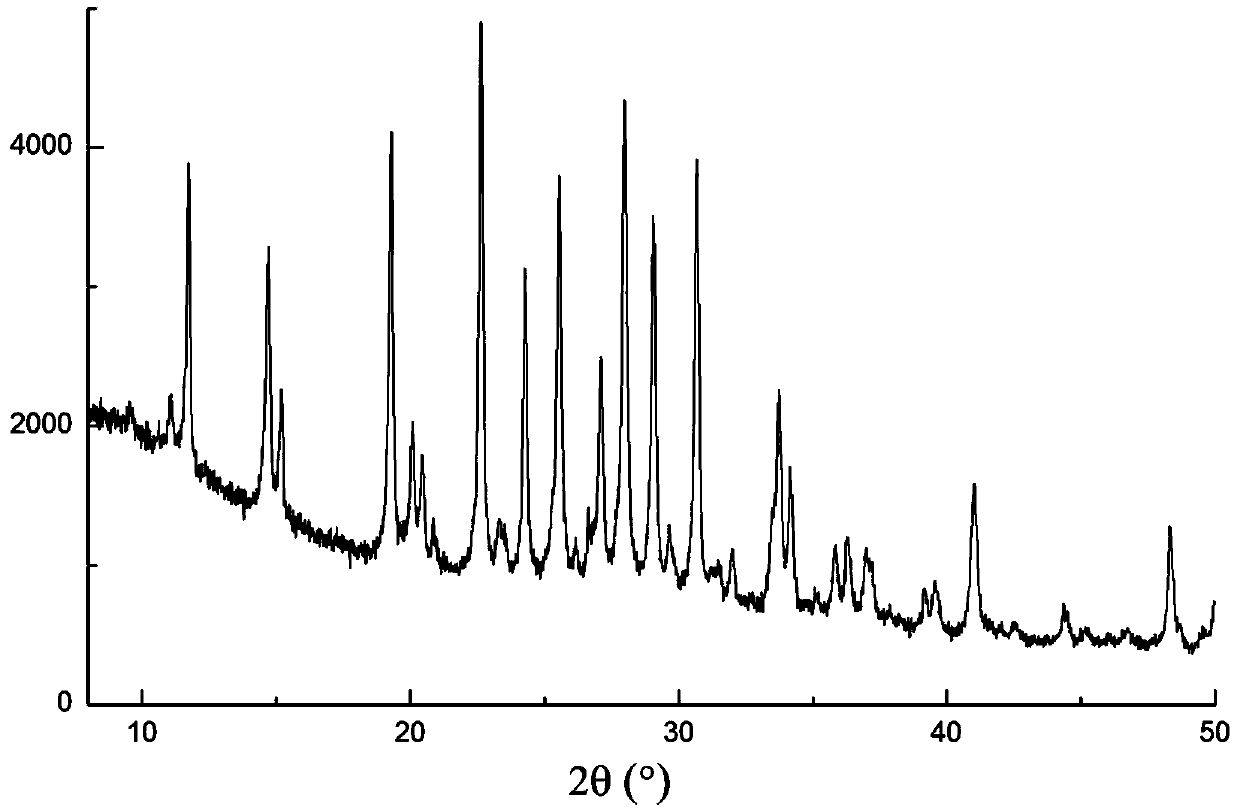

Image

Examples

example 1

[0032] Preforms according to the present invention are prepared.

[0033] Take 100g of kaolin and 5g of methyl cellulose, mix and grind evenly, add 110g of water, knead evenly, and then extrude on an extruder to form a clover-shaped strip with a diameter of 2mm, dry it at 120°C for 12h, and cut it into short pieces with a length of 5-10mm. Rod-shaped, calcined at 900°C for 3 hours to obtain preform K-1, the molar ratio of silica / alumina is 1.7, and the specific surface area is 36m 2 / g, the pore volume is 0.04mL / g.

example 2

[0035] Prepare the preform.

[0036] Take 100g of kaolin and 5g of methyl cellulose, mix and grind evenly, add 110g of water, knead evenly and extrude on the extruder to obtain clover-shaped strips with a diameter of 2mm, dry at 120°C for 12h, and cut into short sticks with a length of 5-10mm , calcined at 550°C for 6h to obtain preform K-2 with a molar ratio of silica / alumina of 1.96 and a specific surface area of 32m 2 / g, the pore volume is 0.032mL / g.

example 3

[0038] In this example, the preform is modified with alkali and steam.

[0039] Take 15g of preform K-1, add it to 20mL KOH solution with a mass fraction of 10%, treat it at 60°C for 2h, then filter, then put the preform into a reaction tube, heat up to 550°C, and pour 500g Steam treatment for 3 hours, take it out, wash it with deionized water, and dry it at 120°C for 12 hours to obtain a modified preform KA-1 with a silica / alumina molar ratio of 4.8 and a specific surface area of 95m 2 / g, the pore volume is 0.15mL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com