KL molecular sieve and morphology regulation synthesis method thereof

A synthesis method and technology of molecular sieves, applied in the field of molecular sieves, can solve the problems of increased production costs of KL molecular sieves, and achieve the effects of synthesis and cost advantages, high yield and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

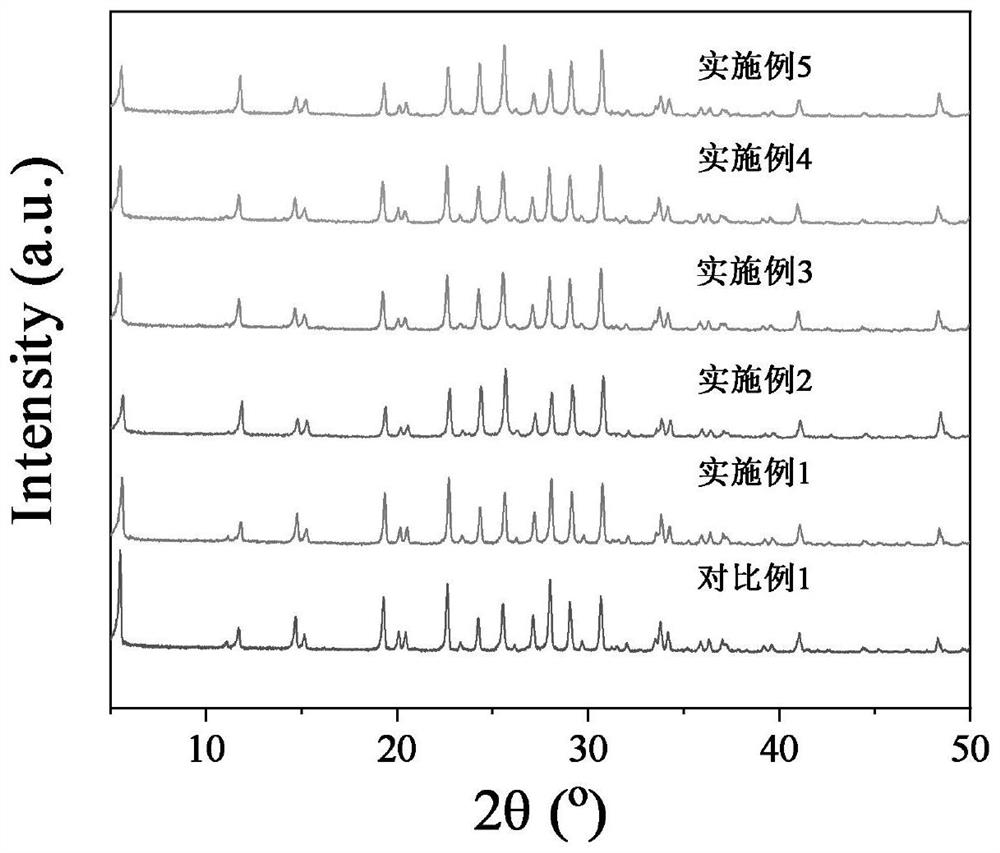

[0036] Weigh 13.66g KOH and dissolve in appropriate amount of water, then weigh 4.50g Al(OH) 3 Add, stir and heat to reflux in a three-necked flask until Al(OH) 3 Dissolve completely to make the solution clear; after the solution is cooled, transfer it to a beaker, add 8.82g KCl and the remaining water and stir evenly, then weigh 68.11g of silica sol (SiO 2 content 30wt.%) was slowly added dropwise to the above solution, stirred and aged at room temperature for 20 hours to obtain a synthetic liquid of KL molecular sieve, and the molar ratio of each material in the synthetic liquid was 4.0KCl: 3.5K 2 O: 11.5SiO 2 : 1.0Al 2 o 3 : 292.65H 2 O. Transfer the above synthetic solution to a polytetrafluoroethylene-lined crystallization kettle, and conduct static hydrothermal crystallization at 175°C for 24 hours. The resulting product is filtered by suction, washed with deionized water until neutral, and then dried at 120°C for 24 hours to obtain KL molecular sieve. Raw powder, ...

Embodiment 2

[0039] Weigh 13.66g KOH and dissolve in appropriate amount of water, then weigh 4.50g Al(OH) 3 Add, stir and heat to reflux in a three-necked flask until Al(OH) 3 Dissolve completely to make the solution clear; after the solution is cooled, transfer it to a beaker, add 17.64g KCl and the remaining water and stir evenly, then weigh 68.11g of silica sol (SiO2 content 30wt.%) was slowly added dropwise to the above solution, stirred and aged at room temperature for 20h to obtain a KL molecular sieve synthetic liquid, and the molar ratio of each material in the synthetic liquid was 8.0KCl: 3.5K 2 O: 11.5SiO 2 : 1.0Al 2 o 3 : 292.65H 2 O. Transfer the above synthetic solution to a polytetrafluoroethylene-lined crystallization kettle, and conduct static hydrothermal crystallization at 175°C for 24 hours. The resulting product is filtered by suction, washed with deionized water until neutral, and then dried at 120°C for 24 hours to obtain KL molecular sieve. Raw powder, the yield...

Embodiment 3

[0042] Weigh 13.66g KOH and dissolve in appropriate amount of water, then weigh 4.50g Al(OH) 3 Add, stir and heat to reflux in a three-necked flask until Al(OH) 3 Dissolve completely to make the solution clear; after the solution is cooled, transfer it to a beaker, add 26.46g KCl and the remaining water and stir evenly, then weigh 68.11g of silica sol (SiO 2 content 30wt.%) was slowly added dropwise to the above solution, stirred and aged at room temperature for 20h to obtain a KL molecular sieve synthetic liquid, and the molar ratio of each material in the synthetic liquid was 12.0KCl: 3.5K 2 O: 11.5SiO 2 : 1.0Al 2 o 3 : 292.65H 2 O. Transfer the above synthetic solution to a polytetrafluoroethylene-lined crystallization kettle, and conduct static hydrothermal crystallization at 175°C for 24 hours. The resulting product is filtered by suction, washed with deionized water until neutral, and then dried at 120°C for 24 hours to obtain KL molecular sieve. Raw powder, the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com