Method for crystallization synthesis of L zeolite molecular sieve with kleit in situ

A technology of kaolin and molecular sieves, applied in the direction of crystalline aluminosilicate zeolite, L-type crystalline aluminosilicate zeolite, etc., can solve the problems of poor flexibility in component modulation, achieve high crystallinity, and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

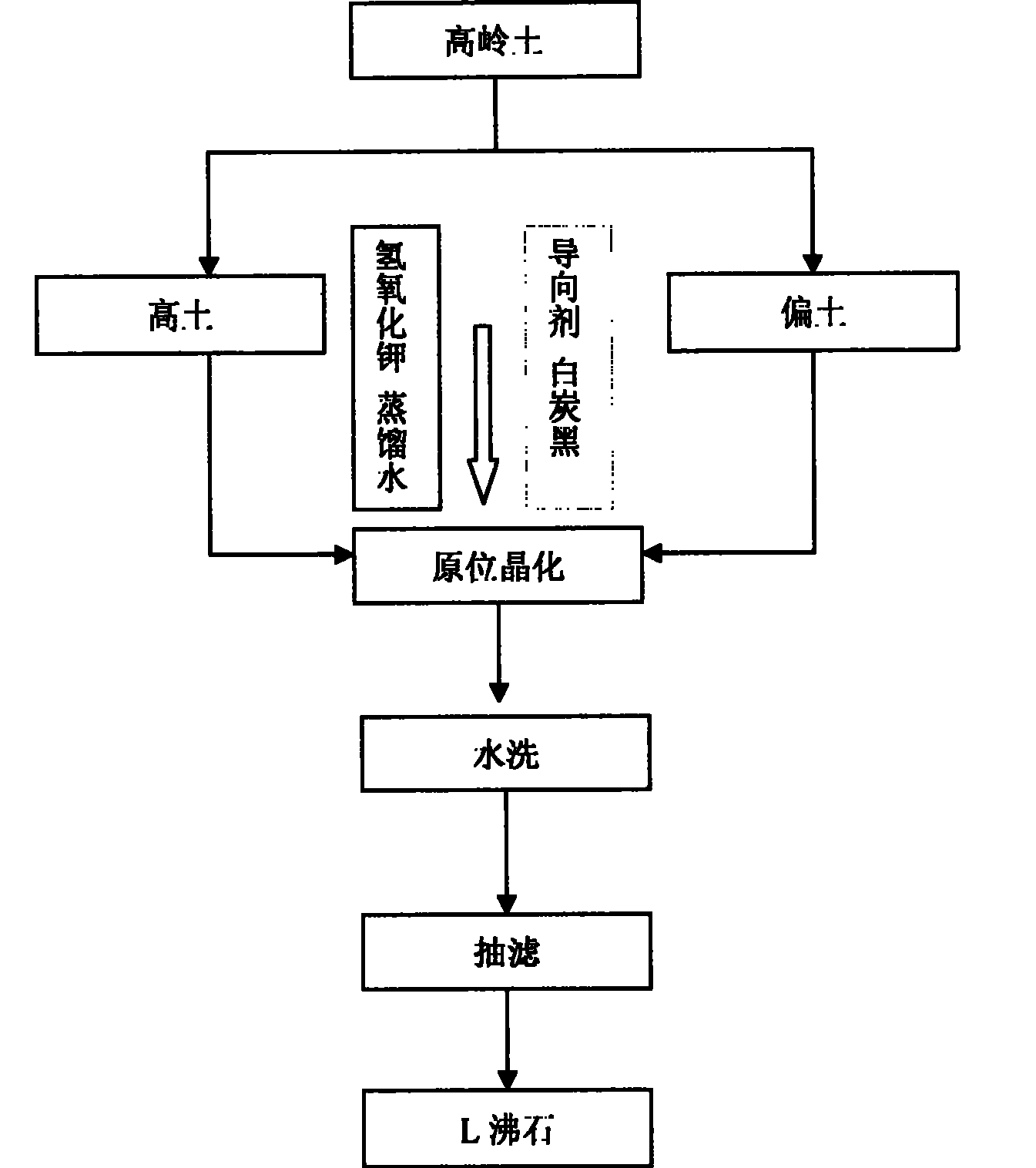

Method used

Image

Examples

example 1

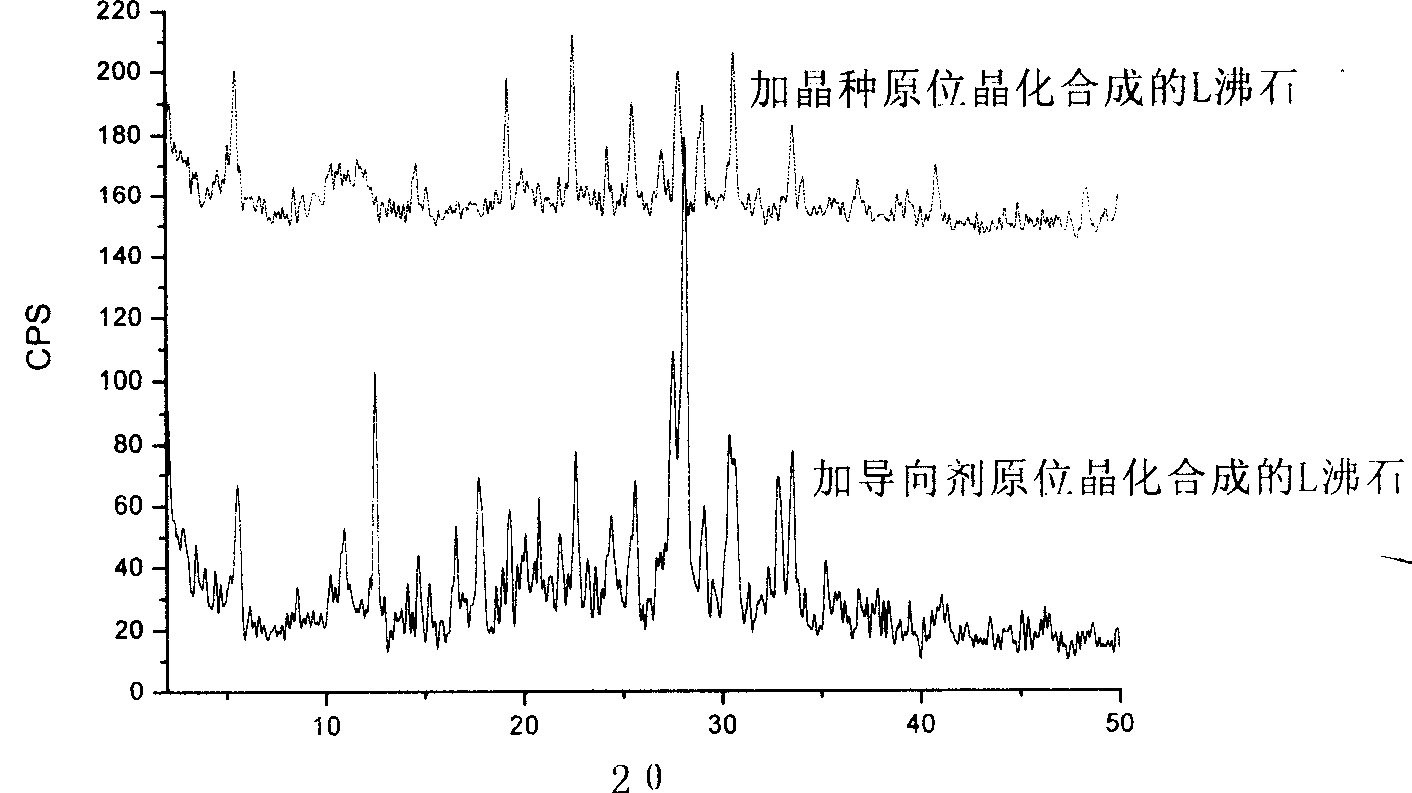

[0024] Take 0.3% (based on the mass of kaolin) L zeolite as a seed crystal, grind it to make it pass through a 0.105mm sample sieve, add distilled water, and disperse with ultrasonic waves for half an hour. Then add 2.6316 grams of white carbon black, 4.5319 grams of potassium hydroxide, 26.8758 grams of distilled water, 2 grams of earth, 8 grams of high earth, stir it evenly, age at room temperature for 24 hours, drop into a stainless steel reactor, heat up to 120°C and stirred at constant temperature for crystallization for 24 hours. After the crystallization is completed, the mother liquor is removed by filtration, washed, and the filter cake is dried to obtain a crystallized product. Its XRD spectrum is attached figure 2 .

example 2

[0026] Get 1 gram of guiding agent, 4.3853 grams of potassium hydroxide, 26.1032 grams of distilled water, 2.8013 grams of white carbon black, 2 grams of partial soil, 8 grams of high soil, stir well and age at room temperature for 24 hours, put it into a stainless steel reaction kettle, and heat up to 120° C. and stirred at constant temperature for 20 hours for crystallization. After the crystallization was completed, the mother liquor was removed by filtration, washed and dried to obtain a crystallized product. Its XRD spectrum is attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com