Hierarchical pore zeolite molecular sieve preparation method

A technology of zeolite molecular sieve and multi-level pores, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of improved diffusion path and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0015] Step 1: At room temperature, mix 1.28g sodium metaaluminate, 1.89g sodium hydroxide, 18ml silica sol and 54ml distilled water to form a uniform white jelly, put it into a stainless steel reaction kettle, and conduct hydrothermal treatment at 170°C for 24 hours , then vacuum filtration, and retain the filtrate for subsequent use;

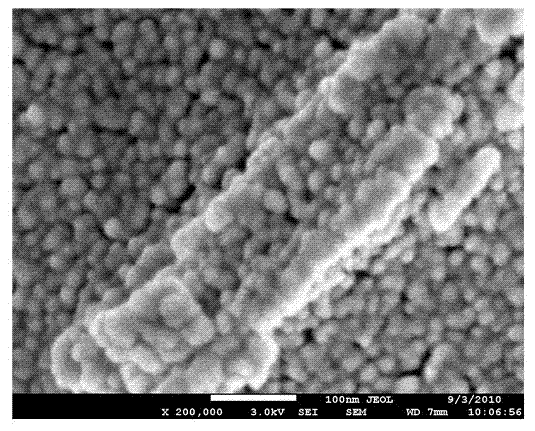

[0016] Step 2: Take 55ml of the above-mentioned filtrate, add 12.5g template agent tetraethylammonium bromide TEABr, 6ml ammonia water and 3ml silica sol to the filtrate, stir evenly, crystallize at 140 degrees Celsius for 7 days, then cool with tap water To room temperature, the product was washed with distilled water until neutral, filtered, dried in an oven at 100°C for 12 hours, and calcined in a muffle furnace at 550°C for 6 hours under the condition of ventilation to obtain the final sample. Analysis by XRD and SEM shows that the obtained sample is a ZSM-12 polycrystalline aggregate of about 10 microns in size composed of nano-sized grai...

Embodiment approach 2

[0019] Step 1: At room temperature, mix 1.28g sodium metaaluminate, 1.89g sodium hydroxide, 18ml silica sol and 54ml distilled water to form a uniform white jelly, put it into a stainless steel reaction kettle, and conduct hydrothermal treatment at 170°C for 24 hours , then vacuum filtration, and retain the filtrate for subsequent use;

[0020] The second step: take 50ml of the above-mentioned filtrate, add 10g template agent tetraethylammonium bromide TEABr, 5ml ammonia water and 15ml silica sol to the filtrate, stir evenly, crystallize at 170 degrees Celsius for 4 days, then cool with tap water to At room temperature, the product was washed with distilled water until neutral, filtered, dried in an oven at 100°C for 12 hours, and calcined in a muffle furnace at 550°C for 4 hours under air ventilation to obtain the final sample. Analysis by XRD and SEM shows that the obtained sample is a ZSM-12 polycrystalline aggregate of about 50 microns overall composed of nano-sized grains...

Embodiment approach 3

[0023] Step 1: At room temperature, mix 1.28g sodium metaaluminate, 1.89g sodium hydroxide, 18ml silica sol and 54ml distilled water to form a uniform white jelly, put it into a stainless steel reaction kettle, and conduct hydrothermal treatment at 170°C for 24 hours , then vacuum filtration, and retain the filtrate for subsequent use;

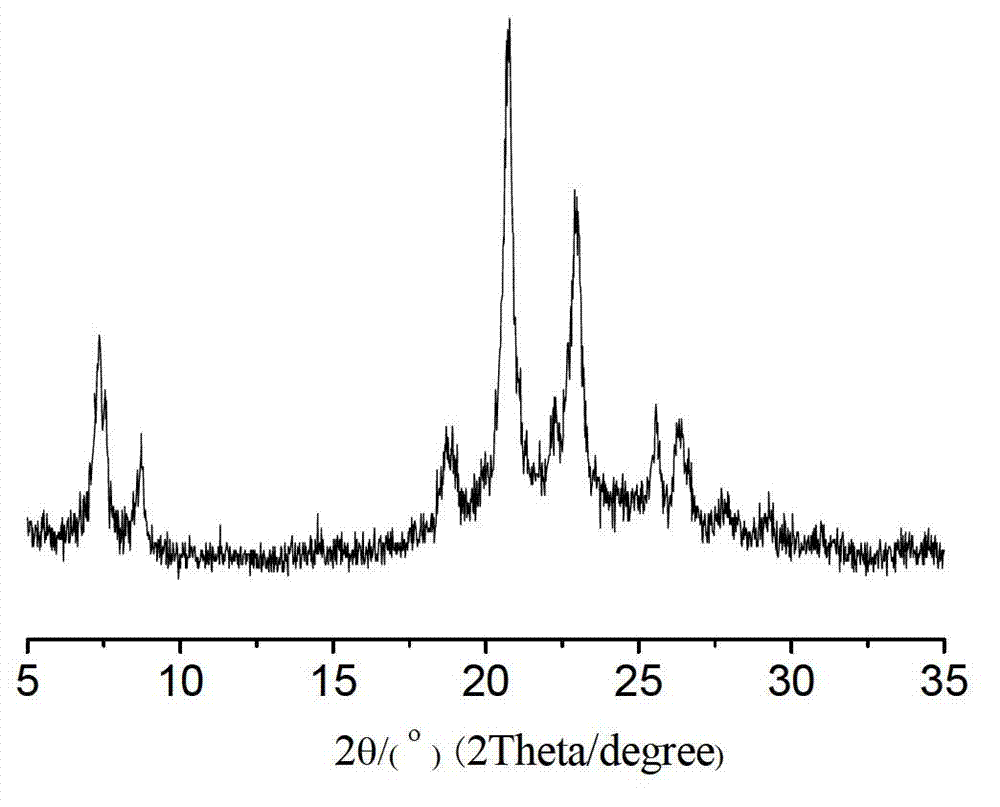

[0024] Step 2: Take 72ml of the above-mentioned filtrate, add 19.3g template agent tetraethylammonium bromide TEABr, 5ml ammonia water and 5ml silica sol to the filtrate, stir evenly, crystallize at 180 degrees Celsius for 5 days, then cool with tap water To room temperature, the product was washed with distilled water until neutral, filtered, dried in an oven at 100°C for 12 hours, and calcined in a muffle furnace at 550°C for 5 hours under the condition of ventilation to obtain the final sample. The XRD characterization results show that the characteristic diffraction peaks of ZSM-12 are obviously broadened, See figure 1 , It is precisel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com