Production device and production process for producing linear alpha-olefin through ethylene selective oligomerization

A production device and selective technology, applied in the production of bulk chemicals, hydrocarbons, hydrocarbons, etc., can solve the problems of difficult long-term continuous operation, low latent heat removal capacity, low reaction temperature, etc., to avoid wall hanging glue And coil bonding oligomer or pipeline blockage, which is conducive to continuous long-term operation and simplifies the effect of separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

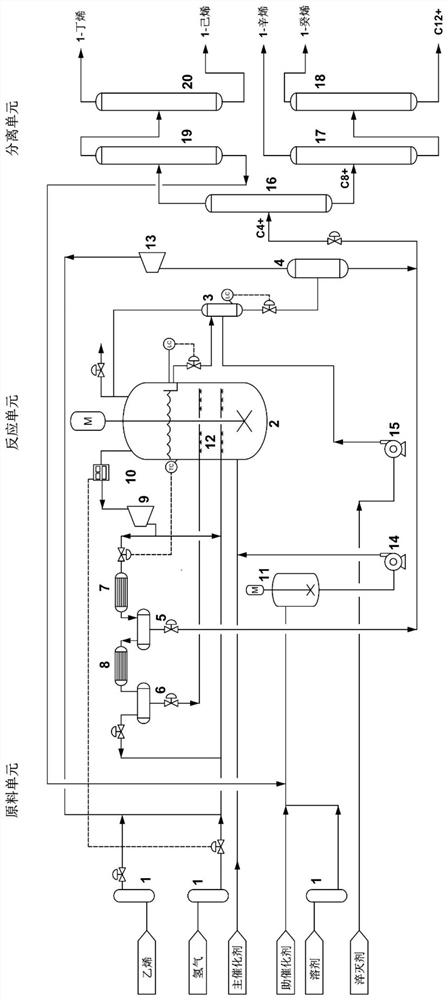

[0065] Such as figure 1 As shown, the oxygen content of ethylene after deoxygenation and dehydration treatment is less than 2ppm, and the water content is less than 2ppm. The feed is fed to the recycle gas inlet of the reactor. The ethylene feed rate is 100kg / h, and the oxygen content of the solvent cyclohexane is less than 2ppm after deoxygenation and dehydration pretreatment. , water content is less than 2ppm, feed to the reactor after saturated ethylene, the solvent feed rate is 200kg / h, the cocatalyst modified methyl aluminoxane is mixed with the solvent cyclohexane to prepare a 10wt.% solution and then directly fed to Reactor, the feed rate of the catalytic solution is 1.0kg / h.

[0066] The main catalyst is the chromium complex described in Example 1 of Chinese Invention Patent 202010718125.3, which is prepared into a 1 μmol / mL solution with the solvent cyclohexane and then directly fed to the reactor. The feed rate of the main catalyst solution is 8.0 kg / h. The regulato...

Embodiment 2

[0084] Refer to Example 1 for the device for selective oligomerization of ethylene. Catalyst selection CN201910966821.3 PNP-type ligands, chromium acetylacetonate complexes and their proportions used in Example 1.

[0085] After ethylene is deoxygenated and dehydrated, the oxygen content is less than 2ppm, and the water content is less than 2ppm. The feed rate of ethylene is 180kg / h, the solvent methylcyclohexane is pretreated by deoxygenation and dehydration, and the oxygen content is less than 2ppm, and the water content is less than 2ppm, and it is directly fed to the tank reactor. The aluminoxane and the solvent methylcyclohexane are mixed and formulated into a 10wt.% solution, and then directly fed into a reaction kettle, and the feeding amount of the catalytic solution is 1.5kg / h. The main catalyst acetylacetonate and the PNP ligand are mixed according to 1:2, and the solvent methylcyclohexane is used to prepare a solution of 1 μmol / mL and then directly fed to the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com