Submicron SAPO-5/SAPO-18 composite molecular sieve and preparation method thereof

A SAPO-18, SAPO-5 technology, applied in the field of sub-micron SAPO-5/SAPO-18 composite molecular sieve and its preparation, can solve the problems of total olefin yield and service life that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preferably, the preparation method of the submicron composite molecular sieve chemically compounded by SAPO-5 molecular sieve and SAPO-18 molecular sieve of the present invention comprises the following steps in sequence:

[0043] (1) Mix the aluminum source, phosphorus source, silicon source, templating agent and water uniformly in proportion at a suitable temperature, for example, at a temperature of 20°C-90°C, to obtain an aluminum source, phosphorus source, silicon source, template agent and The mixed solution of water, in above-mentioned mixed solution, templating agent: SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 The molar ratio of O is (0.2-5.0): (0.1-0.6): 1: (0.7-1.3): 30-200;

[0044] (2) Aging the above mixed solution until a mixed gel is formed;

[0045] (3) Add SAPO-5 / SAPO-18 composite molecular sieve seed crystals to the above mixed gel in proportion to obtain aluminum source, phosphorus source, silicon source, template agent, water and SAPO-5 / SAPO-18 composite mo...

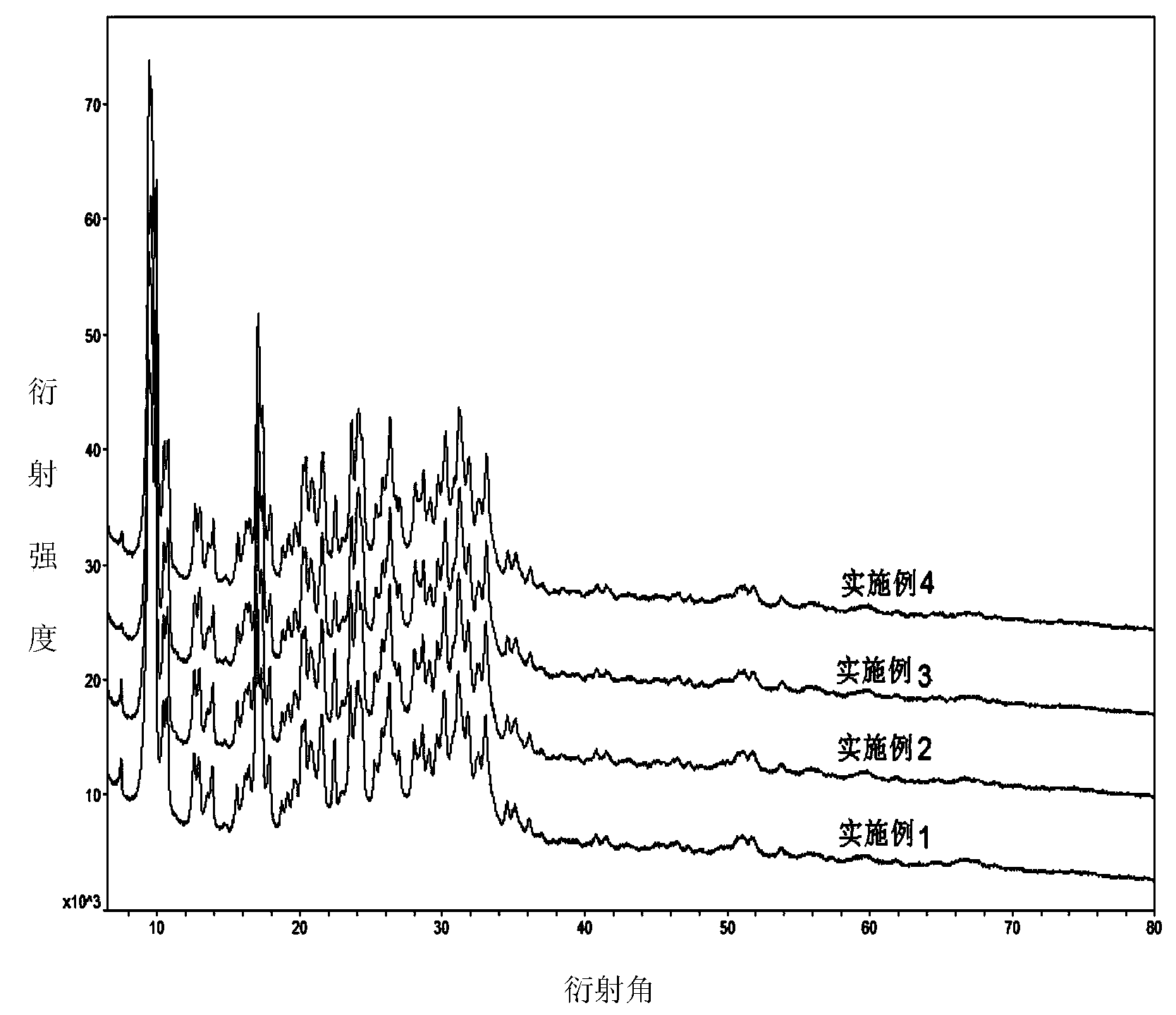

Embodiment 1

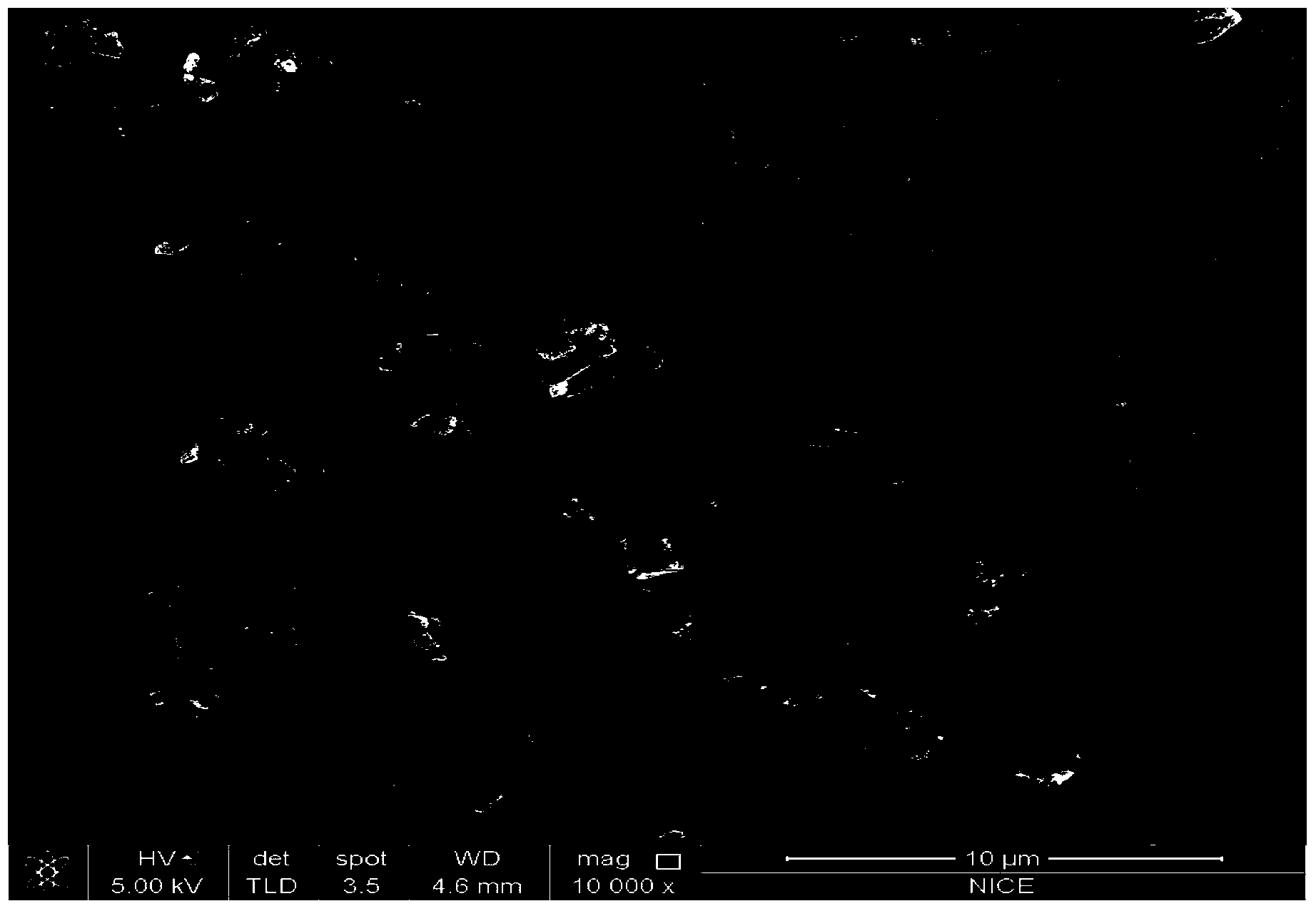

[0058] Embodiment 1: Preparation of submicron SAPO-5 / SAPO-18 chemical composite molecular sieve

[0059] 17.6 grams of pseudo-boehmite and 20.0 grams of deionized water are mixed and stirred to form an aluminum source solution, and 20.0 grams of phosphoric acid with a concentration of 85% by weight are mixed and stirred with 10.0 grams of deionized water to form a phosphorus source solution. The concentration of 2.9 grams is 40% by weight of silica sol and 4.5 grams of deionized water were mixed and stirred to form a silicon source solution.

[0060]Then, the phosphorus source solution is slowly added dropwise to the aluminum source solution to form a mixed solution of the aluminum source and the phosphorus source, and then the silicon source solution is added to the mixed solution of the aluminum source and the phosphorus source. Stir evenly for 1 hour to form a mixed solution of aluminum source, phosphorus source and silicon source, then add 18.8 grams of N,N-diisopropylethy...

Embodiment 2

[0066] Embodiment 2: Preparation of submicron SAPO-5 / SAPO-18 chemical composite molecular sieve

[0067] Except adding 0.5 gram in the mixed solution, instead of the mol ratio of 0.2 gram SAPO-5 molecular sieve / SAPO-18 molecular sieve being the SAPO-5 / SAPO-18 composite molecular sieve seed crystal of 0.3, repeat the process of implementing Lee 1, obtain sub Micron SAPO-5 / SAPO-18 composite molecular sieve, this composite molecular sieve is labeled as molecular sieve B.

[0068] In the above-mentioned preparation process, in the above-mentioned mixed solution, template agent: SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 The mol ratio of O is 1.6:0.2:1:0.95:50; In the above-mentioned mixed gel, take the weight of effective solid content in the mixed gel as a basis, the add-on of SAPO-5 / SAPO-18 compound molecular sieve crystal seed is 2.8%.

[0069] The SAPO-5 / SAPO-18 composite molecular sieve seed crystal whose molar ratio of SAPO-5 molecular sieve / SAPO-18 molecular sieve is 0.3 is SAPO-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com