High-silica octagonal zeolite and synthesizing method thereof

A faujasite and zeolite technology are applied in the field of faujasite and its preparation, can solve the problems of low production efficiency, long crystallization time and the like, and achieve the effects of short synthesis time, low sodium content and reduction of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

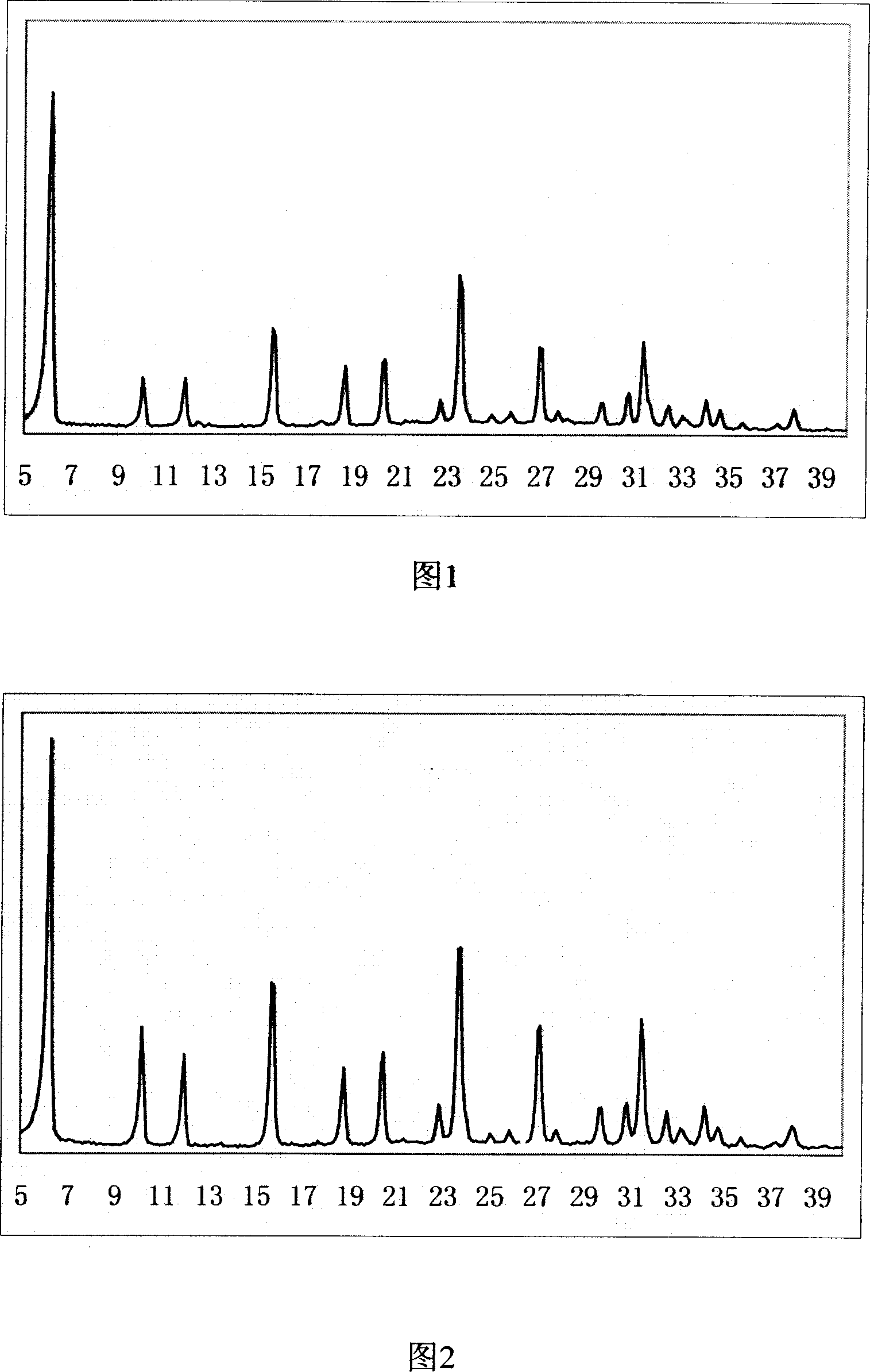

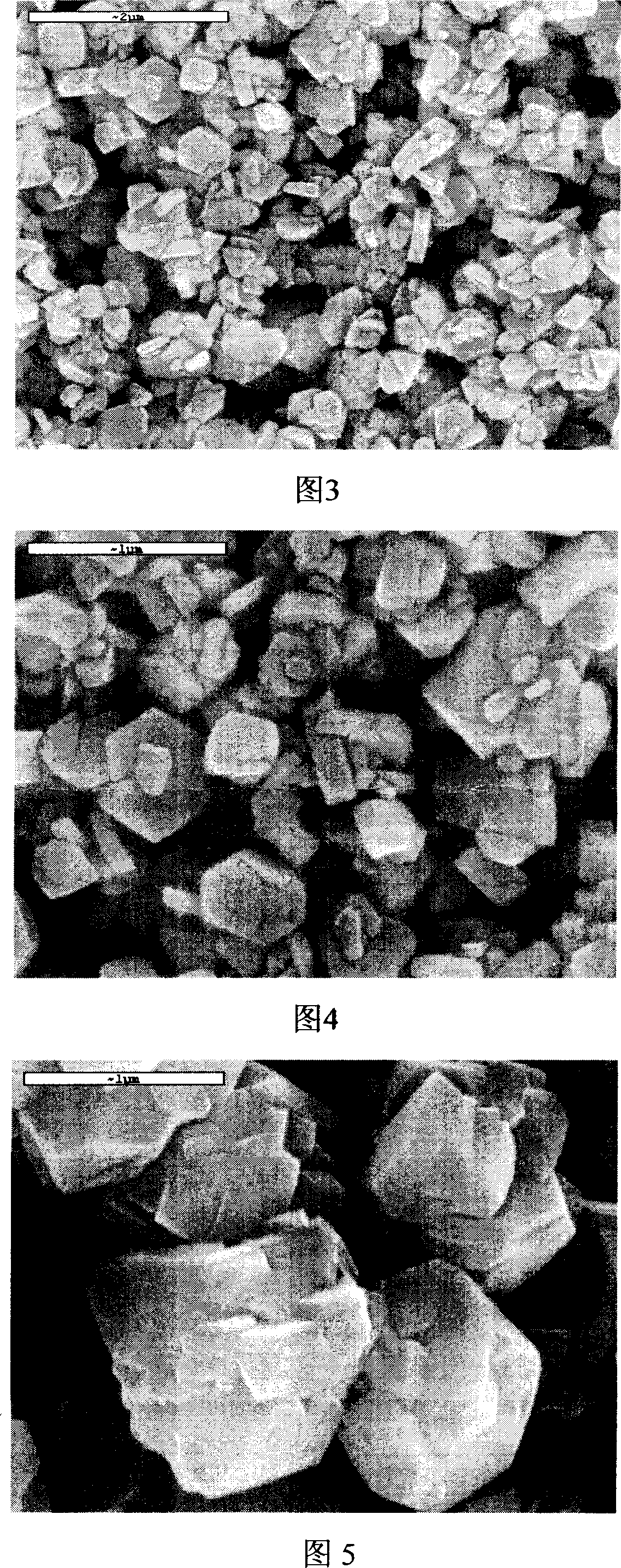

[0033] Using silica sol as a silicon source, sodium aluminate as an aluminum source, and tetraethylammonium hydroxide as a template, the zeolite of the invention is synthesized by hydrothermal crystallization. Reactant ingredients molar ratio: n(SiO 2 ):n(template):n(Na 2 O):n(Al 2 o 3 ):n(H 2 (0)=8:0.8:3.5:1:140. Synthesis method: add sodium hydroxide and sodium aluminate into 20% tetraethylammonium hydroxide solution according to the proportion of reactants, mix well and then add silica sol. The above mixture was stirred at 40°C for 6 hours, then aged at room temperature for 24 hours, moved into an autoclave, sealed, and statically crystallized at 110°C for 120h. After crystallization, the product was filtered, washed with water, dried at 110°C, and then calcined at 550°C to remove the template agent to obtain sample A. A SiO 2 / Al 2 o 3 The molar ratio is 7.2, the XRD diagram is shown in Figure 1, and the electron microscope diagram is shown in Figure 3.

Embodiment 2

[0035] The zeolite of the invention is synthesized by hydrothermal crystallization with water glass as silicon source, sodium aluminate as aluminum source and polyethylene glycol 6000 as template. Reactant ingredients molar ratio: n(SiO 2 ):n(template):n(Na 2 O):n(Al 2 o 3 ):n(H 2 (0)=6:0.16:2.0:1:130. Synthesis method: according to the molar ratio of reactants, dissolve sodium hydroxide and sodium aluminate in water, stir for 30 minutes, add polyethylene glycol 6000, continue stirring until dissolved, and then add silica sol. After the above mixture was stirred at 30°C for 12 hours, it was placed at room temperature overnight and then transferred into an autoclave with polytetrafluoroethylene, sealed and crystallized at 110°C for 120h under stirring (100 rpm). After crystallization, the product was filtered, washed with water, dried at 110°C, and then calcined at 550°C to remove the template to obtain sample B. B SiO 2 / Al 2 o 3 The molar ratio is 10.6, the XRD diagr...

Embodiment 3

[0037] The zeolite of the invention is synthesized by hydrothermal crystallization with water glass as silicon source, aluminum chloride as aluminum source and tetraethylammonium hydroxide as template. Reactant ingredients molar ratio: n(SiO 2 ):n(template):n(Na 2 O):n(Al 2 o 3 ):n(H 2 (0) = 15:0.5:6.0:1:170. Synthesis method: Add sodium hydroxide and sodium aluminate into 20% tetrapropyl ammonium hydroxide solution according to the molar ratio of reactants, mix well and then add silica sol. The above mixture was stirred at 40°C for 6 hours, then aged at room temperature for 24 hours, moved into an autoclave, sealed, first crystallized at 110°C at static state for 24h, and then crystallized at 110°C at dynamic state for 48h (stirring speed 200 rpm Minute). After crystallization, the product was filtered, washed with water, dried at 110°C, and then calcined at 550°C to remove the template agent to obtain sample C. C SiO 2 / Al 2 o 3 The molar ratio was 9.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com